A cable strengthening line

A technology for reinforcing wires and cables, applied in the field of cable reinforcing wires, can solve the problems of easy to disperse, affect the tensile force of fibers, affect the electrical properties of cables, etc., to increase wear resistance and toughness, reduce wire breakage, Improve the effect of solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

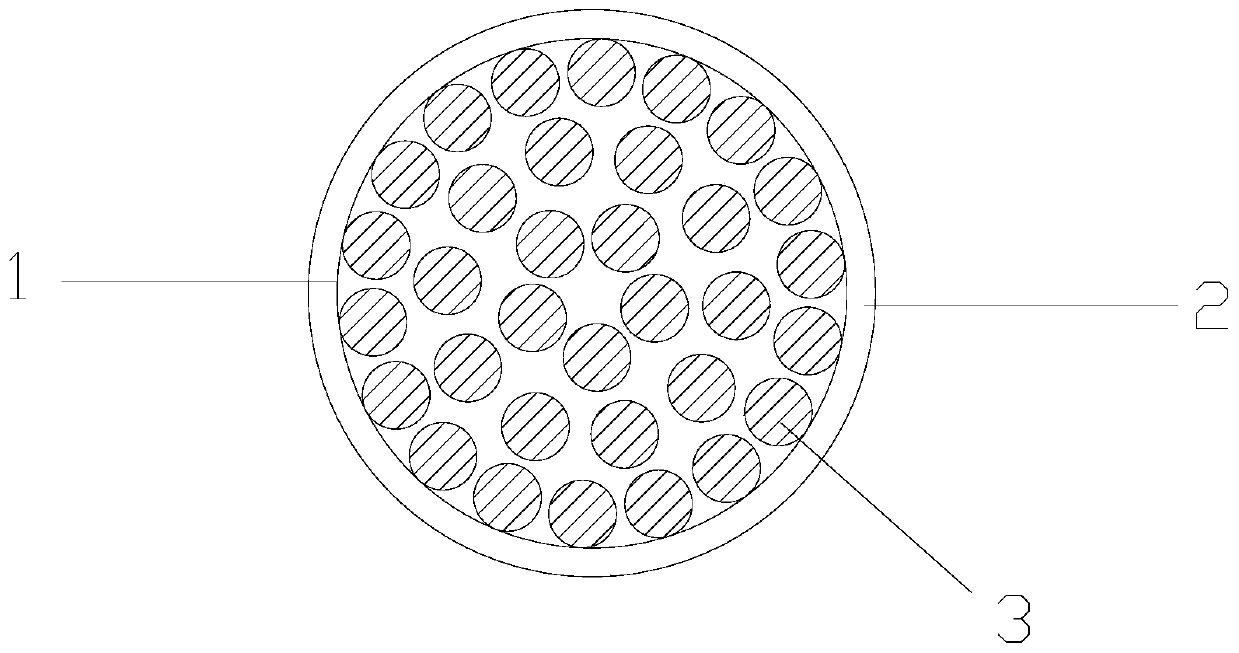

[0018] like figure 1 As shown, a cable reinforcing wire includes a fiber tow 1 and a colloidal coating 2. The fiber tow 1 is formed by twisting 72 fiber filaments 3, and the twisting direction is S. The fiber tow 3 is a polyester fiber filament with a diameter of 3.5 μm; colloidal adhesive is filled between the fiber filaments 3, and the colloidal adhesive is a flexible adhesive; the colloidal coating 2 is compounded on On the outside of the fiber tow 1, the colloidal coating 2 is a colloidal coating 2 made of a flexible adhesive, which is a water-based product of NeoRezR-972 produced by DSM Co., Ltd. polyurethane emulsion.

Embodiment 2

[0020] like figure 1 As shown, a cable reinforcing wire includes a fiber tow 1 and a colloidal coating 2. The fiber tow 1 is formed by twisting 100 fiber filaments 3, and the twisting direction is in the Z direction. The fiber tow 3 is The liquid crystal polyarylate fiber filament has a diameter of 5 μm; the fiber filament 3 is filled with a colloidal adhesive, and the colloidal adhesive is a flexible adhesive; the colloidal coating 2 is compounded on the The outside of above-mentioned fiber tow 1, this colloid coating 2 is the colloid coating 2 that is made by flexible adhesive, and this flexible adhesive is the Bondi glue that brand is Verich, model is VRH-101. White carbon black is added to the flexible adhesive, and the amount of white carbon black added is 3% of the weight of the flexible adhesive.

Embodiment 3

[0022] like figure 1 As shown, a cable reinforcing wire includes a fiber tow 1 and a colloidal coating 2. The fiber tow 1 is formed by twisting 133 fiber filaments 3, and the twisting direction is S-direction. The fiber filaments 3 are Aramid filaments with a diameter of 1.5 μm; colloidal binders are filled between the fiber filaments 3, and the colloidal binders are flexible binders; the colloidal coating 2 is compounded on the fibers The outer side of tow 1, this colloid coating 2 is the colloid coating 2 that is made by flexible adhesive, and this flexible adhesive is polyvinyl butyral adhesive, and it is by weight fraction Made of the following components: polyvinyl butyral 10%, ethanol 90%. White carbon black and graphene powder are added in the flexible adhesive, and the addition amounts of white carbon black and graphene powder are respectively 3% and 30% of the weight of the flexible adhesive.

[0023] Compared with the existing cable reinforcing wire, the cable rein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com