Method for preparing carbon covered nickel nano grain enhanced silver based composite material

A nano-particle, carbon-coated nickel technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve problems such as uneven dispersion of reinforcement phase, achieve a simple and convenient preparation method, and is conducive to comprehensive performance , the effect of good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The first step, preparation of Ni+Ag catalyst precursor NiO+Ag by deposition-precipitation method 2 o

[0031] Add nickel nitrate hexahydrate and silver nitrate into deionized water at a mass ratio of 0.03:1 to prepare an aqueous solution with a molar concentration of nickel nitrate of 0.01mol / L and simultaneously contain nickel ions and silver ions, and add dropwise to the solution Molar concentration is 1.25mol / L sodium hydroxide solution to pH value is 10, and is precipitated, makes the Ni(OH) of mass ratio Ni:Ag=0.01:1 2 +Ag 2 O binary colloid, the Ni(OH) 2 +Ag 2 The O binary colloid was put into an electric constant temperature drying oven, dehydrated to complete dryness at 250 °C and nitrogen atmosphere, and then placed in a tube furnace for calcination at 300 °C for 3 hours to obtain the Ni+Ag catalyst precursor NiO+Ag 2 O powder;

[0032] The second step is to prepare carbon-coated nickel nanoparticles + silver in-situ composite powder by chemical vapor dep...

Embodiment 2

[0037] The first step, preparation of Ni+Ag catalyst precursor NiO+Ag by deposition-precipitation method 2 o

[0038] With embodiment 1;

[0039] The second step is to prepare carbon-coated nickel nanoparticles + silver in-situ composite powder by chemical vapor deposition

[0040] Except that the catalytic cracking reaction time is 2h, the carbon-coated nickel nanoparticles + silver in-situ composite powder with an average particle size of 28nm is obtained, and the yield of carbon-coated nickel nanoparticles is 0.31%, other processes, conditions and results Same as embodiment 1;

[0041] The third step is to prepare carbon-coated nickel nanoparticles reinforced silver-based composites

[0042] With embodiment 1.

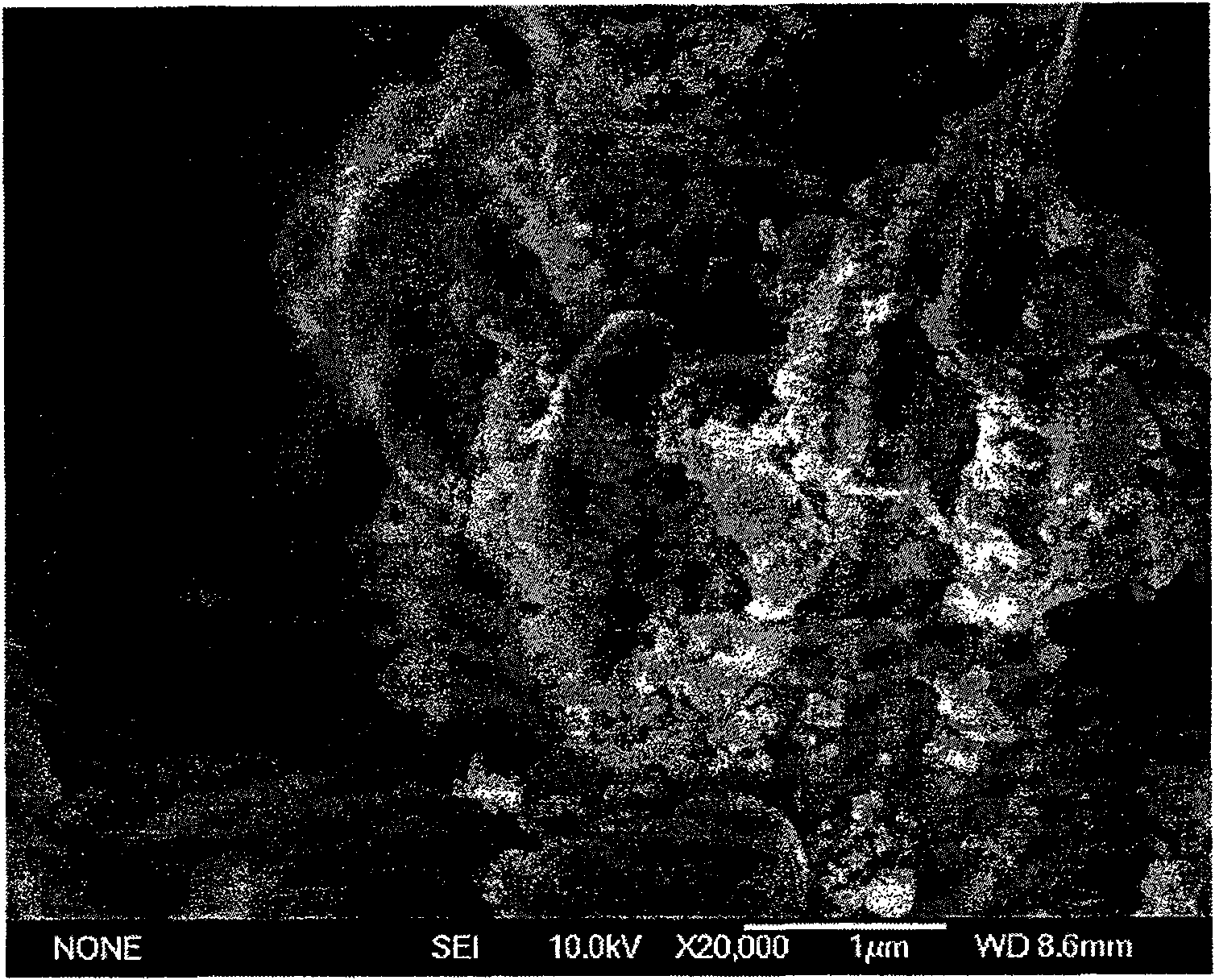

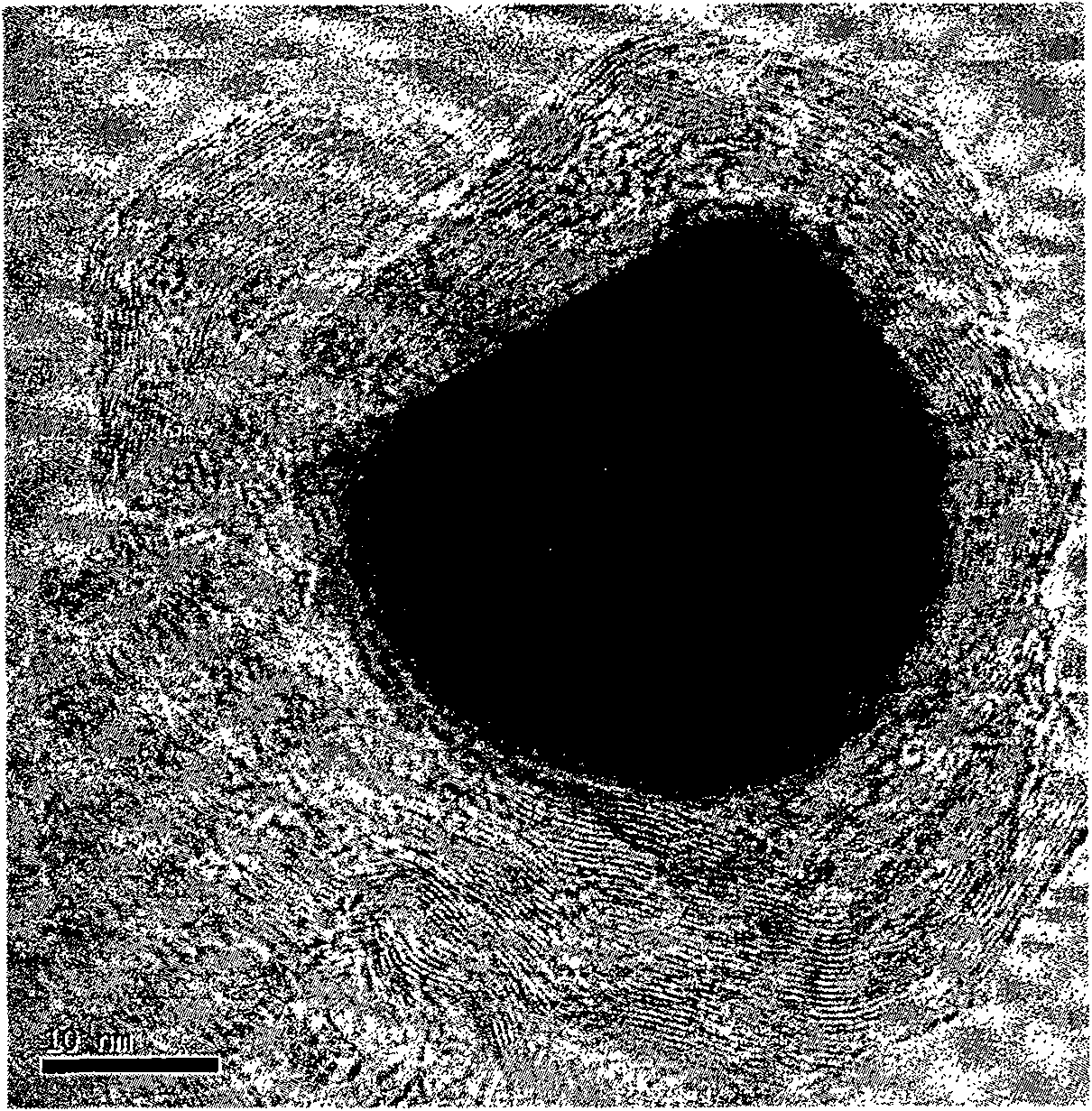

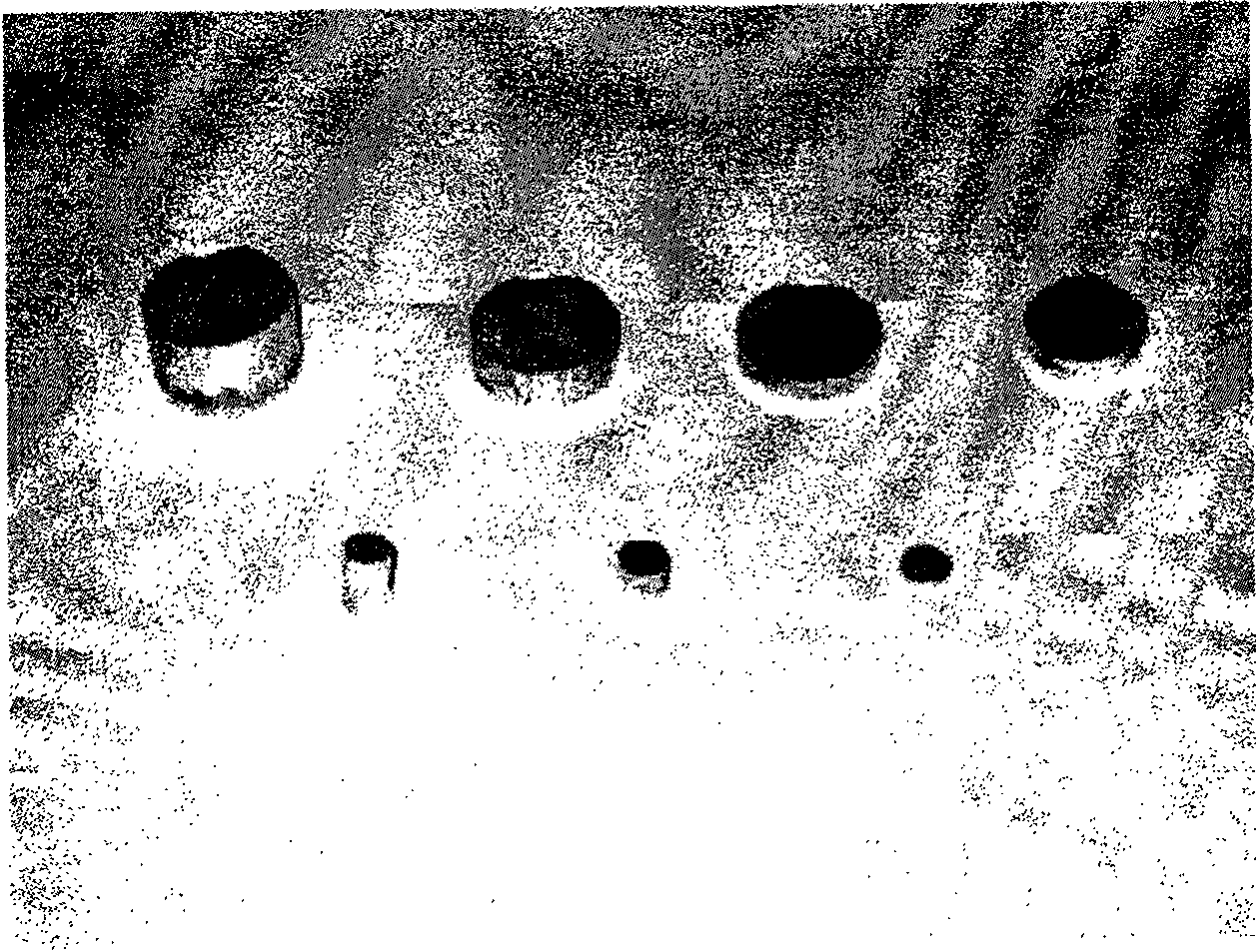

[0043] The high-resolution scanning electron micrograph of the carbon-coated nickel nanoparticles + silver in-situ composite powder obtained in this example is shown in figure 1 , where the high-resolution transmission electron micrographs of carbon-coated nick...

Embodiment 3

[0046] The first step, preparation of Ni+Ag catalyst precursor NiO+Ag by deposition-precipitation method 2 o

[0047] Add nickel nitrate hexahydrate and silver nitrate into deionized water at a mass ratio of 0.17:1 to prepare an aqueous solution containing nickel ions and silver ions with a molar concentration of nickel nitrate of 0.04 mol / L, and add dropwise to the solution Molar concentration is 1.25mol / L sodium hydroxide solution to pH value is 10, and is precipitated, makes the Ni(OH) of mass ratio Ni:Ag=0.05:1 2 +Ag 2 O binary colloid, the Ni(OH) 2 +Ag 2 The O binary colloid was put into an electric constant temperature drying oven, dehydrated to complete dryness at 150 °C and nitrogen atmosphere, and then placed in a tube furnace for calcination at 400 °C for 2 hours to obtain the Ni+Ag catalyst precursor NiO+Ag 2 O powder;

[0048] The second step is to prepare carbon-coated nickel nanoparticles + silver in-situ composite powder by chemical vapor deposition

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com