Preparation method of alloy ceramic thin film, mobile terminal shell and mobile terminal

A technology of alloy ceramics and mobile terminals, which is applied in the coating process and coating of metal materials, etc., can solve the problems of poor texture, environmental pollution, and cumbersome pretreatment procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

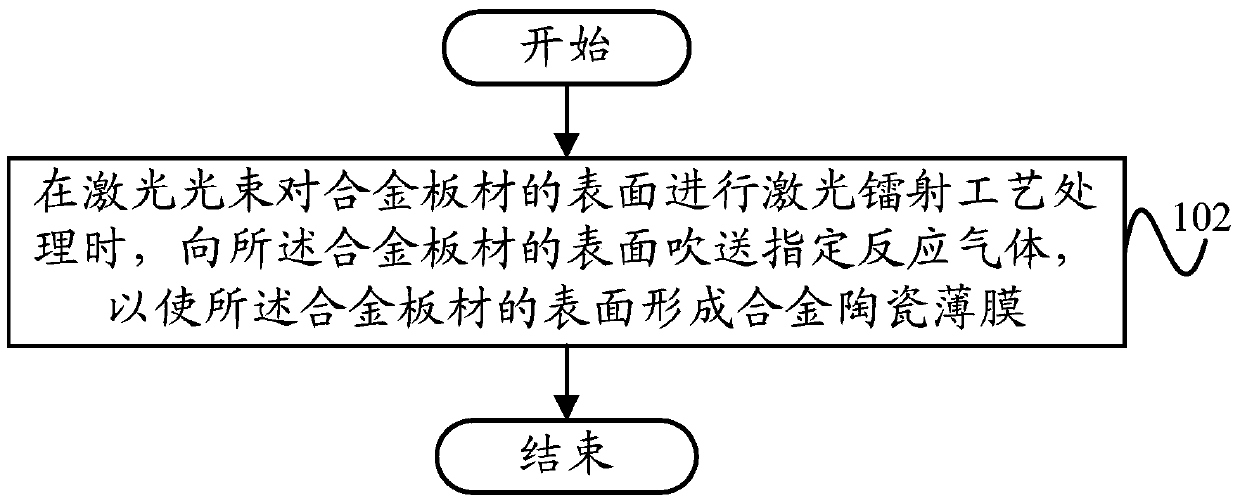

[0029] like figure 1As shown, the present invention proposes a method for preparing an alloy ceramic thin film, including: step 102, when the laser beam performs laser laser process on the surface of the alloy plate, blowing a designated reaction gas to the surface of the alloy plate, so that An alloy ceramic thin film is formed on the surface of the alloy plate.

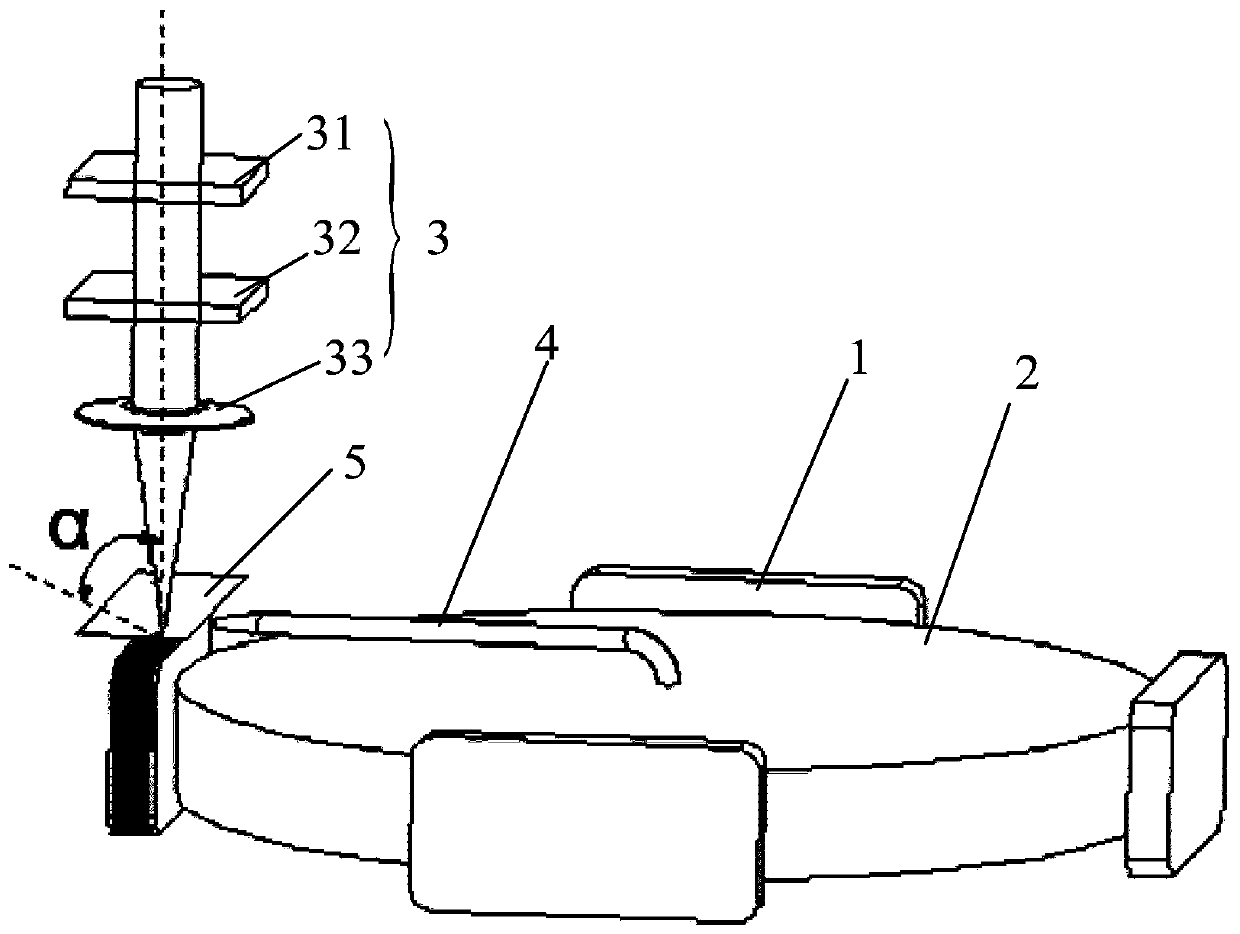

[0030] Specifically, such as figure 2 and image 3 As shown, the alloy plate 1 is selected as the base material, and the alloy plate 1 is processed into the shape of the mobile phone shell, and in order to realize continuous laser coloring of multiple mobile phone shells, multiple mobile phone shells can be rotated according to the computer control program. The body is installed on the assembly line, the assembly line 2 is preferably a rotating disk assembly line, and the mobile phone housing body is located under the laser ablation plasma generator 3, wherein the laser ablation plasma generator 3 emits a laser b...

Embodiment 1

[0047] Select the aluminum alloy with the model number Al7075 as the alloy plate, shape the alloy plate according to the structural design requirements of the mobile phone appearance parts, then polish and clean it, and then make a milky white alloy ceramic film on the surface of the alloy plate, specifically ground, use as figure 2 and image 3 For the shown equipment, the method for preparing the alloy ceramic thin film is as follows: first, oxygen with a purity higher than 3N and nitrogen with a purity higher than 4N are used as the designated reaction gas (wherein, 3N means that the mass purity is 99.9%, and 4N means that the mass purity is 99.9%) 99.99%), and the volume content of oxygen in the mixed gas is not less than 85%, and the flow rate of the mixed gas ranges from 30 milliliters per minute to 40 milliliters per minute; secondly, the chemical composition of the alloy based on Al7075 and the alloy ceramic thin film For the process conditions of the preparation met...

Embodiment 2

[0051] Select titanium alloy with model TC4 or titanium alloy with model TB6 as the alloy plate, shape and process the alloy plate according to the structural design requirements of mobile phone appearance parts, then polish and clean it, and then manufacture on the surface of the alloy plate Royal blue alloy ceramic film, using such as figure 2 and image 3The equipment shown, specifically, the method for preparing the alloy ceramic film is as follows: first, oxygen and acetylene with a purity higher than 3N are used as the designated reaction gas, and the volume content of oxygen in the mixed gas is not less than 95%, and the mixed gas The gas flow rate ranges from 10 ml to 50 ml per minute; clean air can also be used as the designated reaction gas, and the gas flow rate ranges from 10 ml to 50 ml per minute; secondly, based on titanium alloy TC4 or titanium alloy The chemical composition of TB6 and the technological condition of the preparation method of alloy ceramic thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com