Novel high-strength corrosion-resistant aluminum alloy video monitoring unit

A video monitoring, high-strength technology, applied in the direction of metal material coating process, coating, etc., can solve the problem that aluminum alloy does not have the strength and formability of steel, and achieve the effect of saving resources, reducing melting temperature, and enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

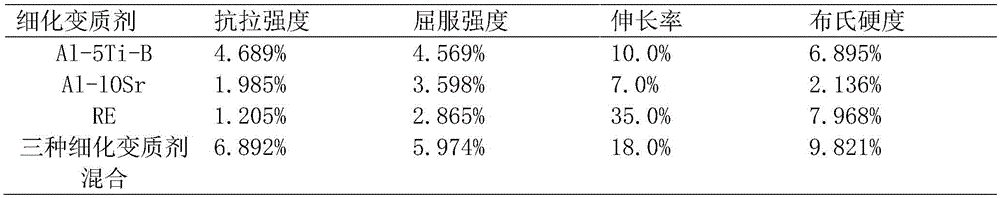

Image

Examples

Embodiment 1

[0017] A new type of high-strength anti-corrosion aluminum alloy video surveillance equipment, including a protective shell, the protective shell includes Mg0.2%, Si2.0%, Cu4.0%, Mn0.2%, Fe0.2%, by weight percentage, Zr0.1%, Er0.1%, Cr0.01%, Ni0.01%, Ti0.1%, Al balance.

[0018] A method for preparing a novel high-strength anti-corrosion aluminum alloy video monitoring device, the protective shell is a shell made by the following steps:

[0019] (1) Preheat the heating furnace and pure aluminum used in smelting at 300°C for 1 to 2 hours; (2) After the preheated pure aluminum is completely melted in a heating furnace with a melting temperature of 750°C under reduced pressure, add single Crystalline silicon particles and single crystal silicon particles are melted and then added with aluminum-copper master alloy, aluminum-manganese master alloy, aluminum-chromium master alloy, aluminum-nickel master alloy, aluminum-iron master alloy, aluminum-zirconium master alloy and a small a...

Embodiment 2

[0030] A new type of high-strength anti-corrosion aluminum alloy video surveillance equipment, including a protective shell, the protective shell includes Mg0.6%, Si3.5%, Cu6.0%, Mn0.3%, Fe0.3%, Zr0.5%, Er0.5%, Cr0.02%, Ni0.02%, Ti0.2%, Al balance.

[0031] A method for preparing a novel high-strength anti-corrosion aluminum alloy video monitoring device, the protective shell is a shell made by the following steps:

[0032] (1) Preheat the heating furnace and pure aluminum used in smelting at 320 for 1 to 2 hours; (2) After the preheated pure aluminum is completely melted in a heating furnace with a melting temperature of 750°C under reduced pressure, add single crystal Silicon particles, single crystal silicon particles are melted and then added with Al-Cu master alloy, Al-Mn master alloy, Al-Cr master alloy, Al-Ni master alloy, Al-Fe master alloy, Al-Zr master alloy and a small amount of rare earth element erbium, and keep warm for a period of time until The master alloy is...

Embodiment 3

[0044] A new type of high-strength anti-corrosion aluminum alloy video monitoring equipment, including a protective shell, the protective shell includes Mg0.6%, Si2.0%, Cu5.0%, Mn0.25%, Fe0.25%, by weight percentage, Zr0.3%, Er0.3%, Cr0.015%, Ni0.015%, Ti0.015%, Al balance.

[0045] A method for preparing a novel high-strength anti-corrosion aluminum alloy video monitoring device, the protective shell is a shell made by the following steps:

[0046] (1) Preheat the heating furnace and pure aluminum used in smelting at 330°C for 1 to 2 hours; (2) After the preheated pure aluminum is completely melted in a heating furnace with a melting temperature of 750°C under reduced pressure, add single Crystalline silicon particles and single crystal silicon particles are melted and then added with aluminum-copper master alloy, aluminum-manganese master alloy, aluminum-chromium master alloy, aluminum-nickel master alloy, aluminum-iron master alloy, aluminum-zirconium master alloy and a sma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current density | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com