A kind of magnesium alloy solder used for rare earth magnesium alloy brazing and preparation method

A technology of magnesium alloy and rare earth magnesium, which is applied in the field of magnesium alloy solder and preparation, can solve the problems of less element burning loss and poor control of temperature changes, and achieve good composition control, no composition pollution, and easy process control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

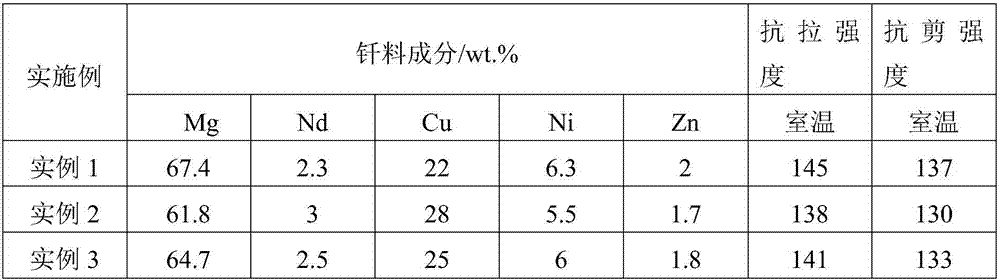

example 1

[0021] Mg-Nd-Cu-Ni-Zn magnesium alloy solder, the solder alloy contains the following components (by weight): 2.3% Nd, 67.4% Mg, 22% Cu, 6.3% Ni, 2% Zn.

[0022] (1) According to the alloy composition 2.3% Nd, 67.4% Mg, 22% Cu, 6.3% Ni, 2% Zn to prepare raw materials, the raw materials used are Cu, Ni and Zn with a purity of more than 99.9% and 95.9% Mg and 3.22% Rare earth magnesium alloys with Nd and trace amounts of other alloying elements;

[0023] (2) Put the prepared raw materials into a graphite crucible, heat and smelt them in a resistance furnace, and use a mixture of potassium chloride and lithium chloride with a mass ratio of 3:1 as a protective agent to cover the raw materials in the smelting process;

[0024] (3) Put the crucible into a resistance furnace, set the temperature to 800°C, and heat it. When the temperature rises to 800°C, stir evenly with a graphite rod and keep warm for 10 minutes. Then the temperature was lowered to 600°C for 10 minutes. Take out...

example 2

[0027] Mg-Nd-Cu-Ni-Zn magnesium alloy solder, the solder alloy contains the following components (by weight): 3% Nd, 61.8% Mg, 28% Cu, 5.5% Ni, 1.7% Zn.

[0028] (1) According to the alloy composition 3% Nd, 61.8% Mg, 28% Cu, 5.5% Ni, 1.7% Zn to prepare raw materials, the raw materials used are Cu, Ni and Zn with a purity of more than 99.9% and 95.9% Mg and 3.22% Rare earth magnesium alloy with Nd and trace amounts of other alloying elements.

[0029] (2) Put the prepared raw materials into a graphite crucible and heat and melt them in a resistance furnace. During the melting process, a mixture of potassium chloride and lithium chloride with a mass ratio of 4:1 is used as a protective agent to cover the raw materials.

[0030] (3) Put the crucible into a resistance furnace, set the temperature to 860°C, and heat it. When the temperature rises to 860°C, stir evenly with a graphite rod and keep warm for 5 minutes. Then lower the temperature to 550°C and keep it warm for 5 minu...

example 3

[0033] Mg-Nd-Cu-Ni-Zn magnesium alloy solder, the solder alloy contains the following components (by weight): 2.5% Nd, 64.7% Mg, 25% Cu, 6% Ni, 1.8% Zn.

[0034] (1) Prepare raw materials according to the alloy composition of 2.5% Nd, 64.7% Mg, 25% Cu, 6% Ni, 1.8% Zn, the raw materials used are Cu, Ni and Zn with a purity of more than 99.9% and 95.9% Mg and 3.22% Rare earth magnesium alloy with Nd and trace amounts of other alloying elements.

[0035] (2) Put the prepared raw materials into a graphite crucible and heat and melt them in a resistance furnace. During the melting process, a mixture of potassium chloride and lithium chloride with a mass ratio of 3.5:1 is used as a protective agent to cover the raw materials.

[0036] (3) Put the crucible into a resistance furnace, set the temperature to 830° C., and heat it. When the temperature rises to 830°C, stir evenly with a graphite rod and keep warm for 8 minutes. Then cool down to 580°C for 8 minutes. Take out the crucib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com