Titanium alloy investment casting precision casting method for product with narrow cavity and complicated structure

A technology of investment precision casting and complex structure, which is applied in the direction of casting molding equipment, molds, cores, etc., to achieve the effects of good inertia, high strength, and avoiding fire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, contents and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the examples.

[0023] This embodiment proposes a titanium alloy investment precision casting method for products with a narrow cavity and complex structure, which specifically includes the following steps:

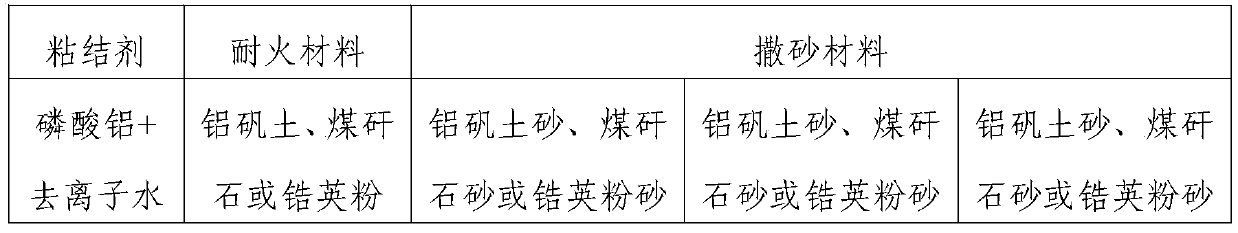

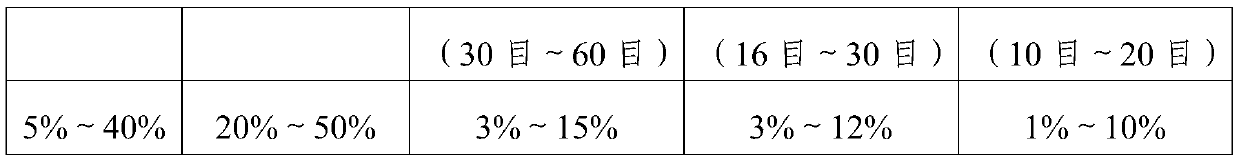

[0024] S1, prepare surface layer calcium carbonate composite slurry

[0025] Add deionized water to the binder zirconium sol, mix well and then add calcium carbonate or a mixture of calcium carbonate and zirconia or a mixture of calcium carbonate and yttrium oxide. The calcium carbonate used is crushed and screened after electric melting or calcining The resulting densified particles of less than 400 mesh, zirconia and yttrium oxide are the particles of less than 320 mesh obtained after crushing and screening after electric melting or calcination; after zirc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com