PVC compound stabilizer and preparation method

A composite stabilizer and main stabilizer technology, which is applied in the field of PVC composite stabilizer and its preparation, can solve the problems of poor material stability, low coloring performance, lead-containing poisonous environment, etc., and achieve good internal and external lubricity and high synergy effect, the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

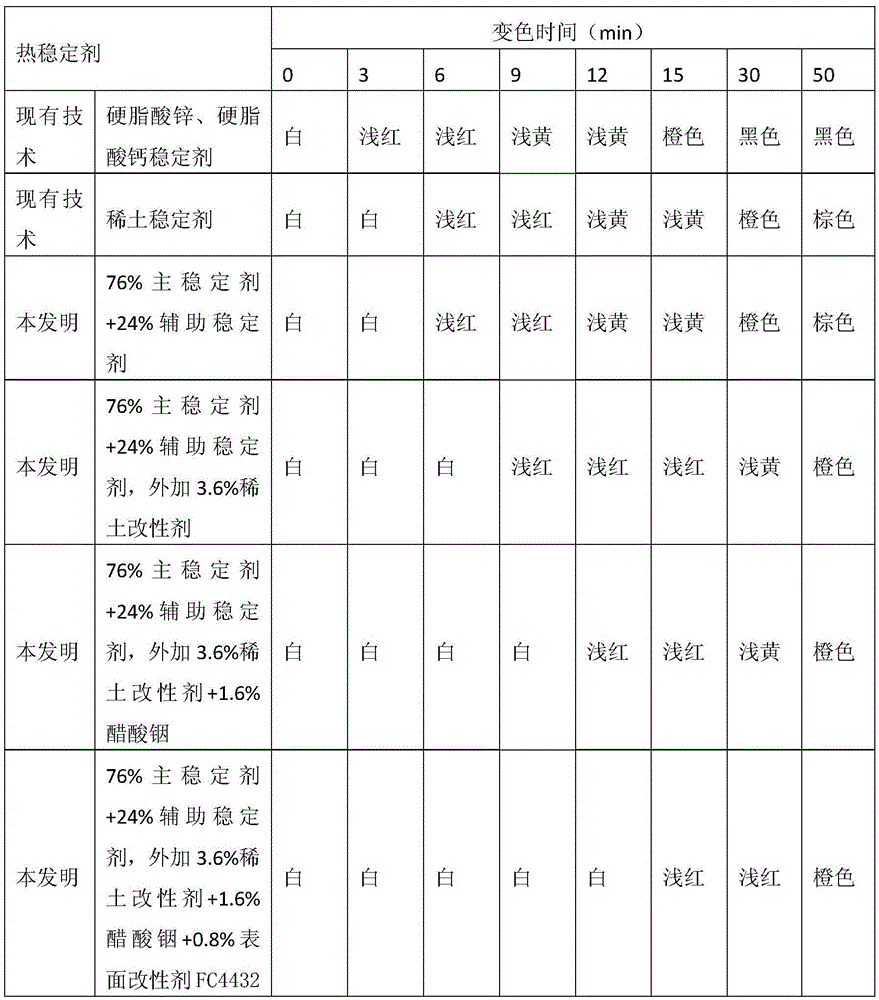

Examples

Embodiment 1

[0028] This embodiment discloses a PVC composite stabilizer, which is composed of a primary stabilizer with a mass fraction of 85-95% and an auxiliary stabilizer with a mass fraction of 5-15%. In this embodiment, the mass fraction can be selected as 60% of the main stabilizer and 40% of the auxiliary stabilizer, of course, can also be a combination of any range, for example, 70% of the main stabilizer and 30% of the auxiliary stabilizer, The main stabilizer with a mass fraction of 75% and the auxiliary stabilizer with a mass fraction of 25%; the main stabilizer is composed of polyvinylpyrrolidone ((C6H9NO)n), zinc pyrrolidone carboxylate (PCA-Na), and disodium edetate Calcium (C 10 H 12 CaN 2 Na 2 O 8 ), tetraisopropyl titanate (C 12 H 28 O 4 Ti), the auxiliary stabilizer is composed of vinyl bisstearamide (C 38 H 76 N 2 O 2 ), pentaerythritol stearate (C 77 H 148 O 8 ), epoxy linseed oil, mannitol (C 6 H 14 O 6 )composition. Among them, polyvinylpyrrolidone ((C6H9NO)n), zinc p...

Embodiment 2

[0032] The formulation components are the same as in Example 1. The difference from Example 1 is that in the PVC composite stabilizer, polyvinylpyrrolidone ((C6H9NO)n), zinc pyrrolidone carboxylate (PCA-Na), calcium disodium ethylenediaminetetraacetate (C10H12CaN2Na2O8), four The mass fractions of isopropyl titanate (C12H28O4Ti) in the composite stabilizer are: 15%, 25%, 45%, and 10%; vinyl bis-stearamide (C38H76N2O2), pentaerythritol stearate (C77H148O8), ring Oxygen linseed oil and mannitol (C6H14O6) accounted for 1%, 2%, 1%, and 1% of the mass fraction of the composite stabilizer, respectively.

[0033] As a further preference, the PVC composite stabilizer is added with a rare earth stabilizer, and the rare earth stabilizer accounts for 6% of the weight of the PVC composite stabilizer, wherein the rare earth stabilizer is yttrium stearate or yttrium maleamic acid or yttrium isooctanoate. The additional rare earth stabilizer is either yttrium stearate, yttrium maleamic acid or...

Embodiment 3

[0037] The formulation components are the same as in Example 1. The difference from Example 1 is that in the PVC composite stabilizer,

[0038] Polyvinylpyrrolidone ((C6H9NO)n), zinc pyrrolidone carboxylate (PCA-Na), calcium disodium edetate (C10H12CaN2Na2O8), and tetraisopropyl titanate (C12H28O4Ti) accounted for the mass fractions of the composite stabilizer, respectively : 15%, 25%, 35%, 15%; vinyl bis-stearamide (C38H76N2O2), pentaerythritol stearate (C77H148O8), epoxy linseed oil, mannitol (C6H14O6) accounted for the mass fraction of composite stabilizer Respectively: 2%, 3%, 2%, 3%.

[0039] The PVC composite stabilizer is also added with rare earth stabilizer and modifier indium acetate: the rare earth stabilizer is a mixture of yttrium stearate, yttrium maleamic acid, and yttrium isooctanoate. The rare earth stabilizer accounts for 4.2 of the quality of the PVC composite stabilizer. %, its composition and component ratio are the same as in Example 2. The added modifier i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com