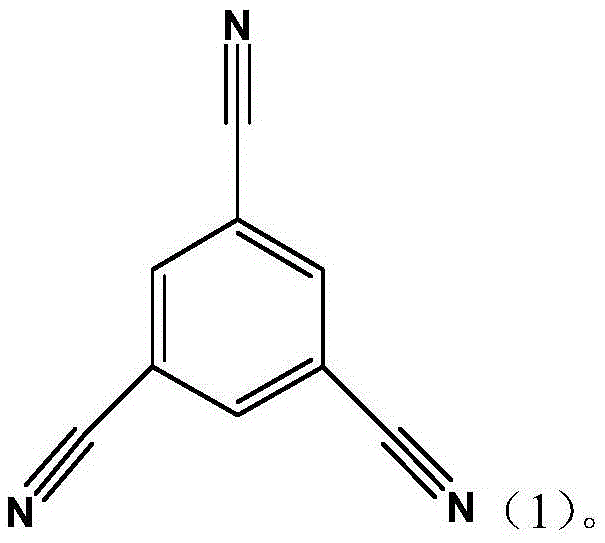

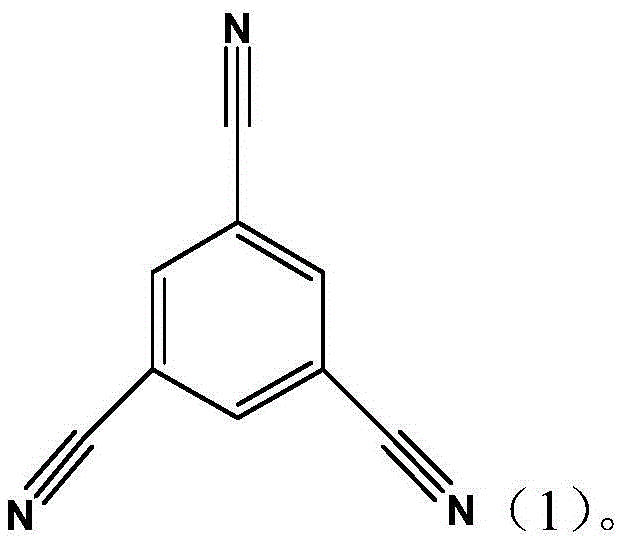

Electrolyte containing tricyanobenzene and lithium ion secondary battery containing electrolyte

A technology of electrolyte and trimellitonitrile, which is applied in the field of designing lithium-ion battery preparation, can solve problems such as electrolyte oxidation, and achieve the effects of inhibiting catalytic decomposition, improving high-temperature storage performance, and inhibiting dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

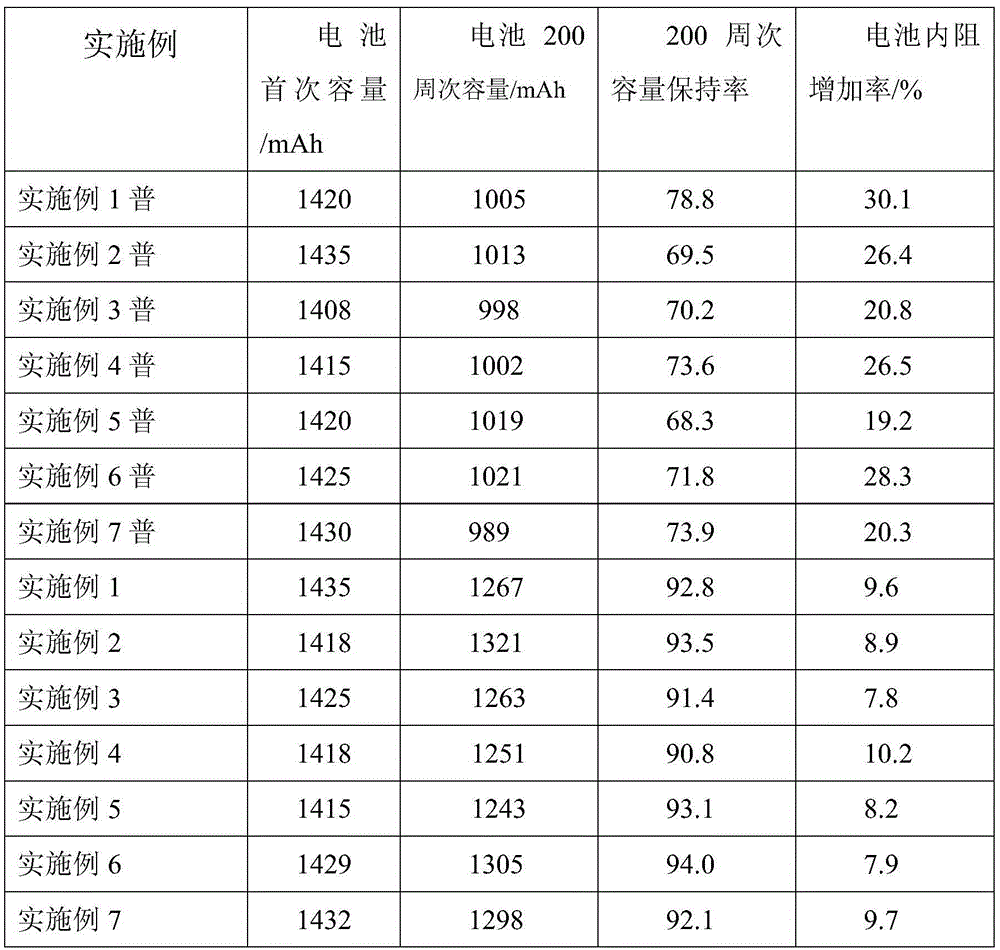

Examples

Embodiment 1

[0027] (1) The cyclic carbonate solvent ethylene carbonate (EC) and the linear carbonate solvent ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) are mass ratio EC:EMC:DEC=3:5:2 Mix, and use molecular sieve, calcium hydride, lithium hydride to purify and remove impurities and water;

[0028] (2) At room temperature, the conductive lithium salt LiPF 6 Dissolve in the solvent obtained in step (1), the final concentration is 1.0mol / L, and stir evenly to obtain a common electrolyte;

[0029] (3) Adding trifluoroethyl trifluoromethanesulfonate to the common electrolyte prepared in step (2), the dosage being 1.5% of the electrolyte quality; obtaining a high-voltage electrolyte for lithium-ion batteries.

Embodiment 2

[0031] (1) The cyclic carbonate solvent ethylene carbonate (EC) and the linear carbonate solvent ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) are mass ratio EC:EMC:DEC=3:5:2 Mixing, using molecular sieves, calcium hydride, lithium hydride to purify and remove impurities and water;

[0032] (2) At room temperature, the conductive lithium salt LiPF 6 Dissolve in the solvent obtained in step (1), the final concentration is 1mol / L, stir evenly, and make common electrolyte;

[0033] (3) Adding trifluoroethyl trifluoromethanesulfonate to the ordinary electrolyte prepared in step (2), the dosage being 0.5% of the electrolyte mass; obtaining a high-voltage functional electrolyte for lithium-ion batteries.

Embodiment 3

[0035] (1) The cyclic carbonate solvent ethylene carbonate (EC) and the linear carbonate solvent ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) are mass ratio EC:EMC:DEC=3:5:2 Mixing, using molecular sieves, calcium hydride, lithium hydride to purify and remove impurities and water;

[0036] (2) At room temperature, the conductive lithium salt LiPF 6 Dissolve in the solvent obtained in step (1), the final concentration is 1.0mol / L, stir evenly, and make common electrolyte;

[0037] (3) adding trifluoroethyl trifluoromethanesulfonate to the ordinary electrolyte prepared in step (2), the dosage being 1% of the electrolyte mass; obtaining a boron-containing film-forming functional electrolyte for lithium-ion batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com