Carborane-containing organic matter and neutron radiation protection material polyester and its preparation

A technology of carborane and organic matter, applied in the fields of compounds containing elements of group 3/13 of the periodic table, organic chemistry, single-component polyester artificial filament, etc. Silk equipment and process complex, poor durability and fastness, etc., to achieve the effect of not easy to wash or rub off, high boron content, good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

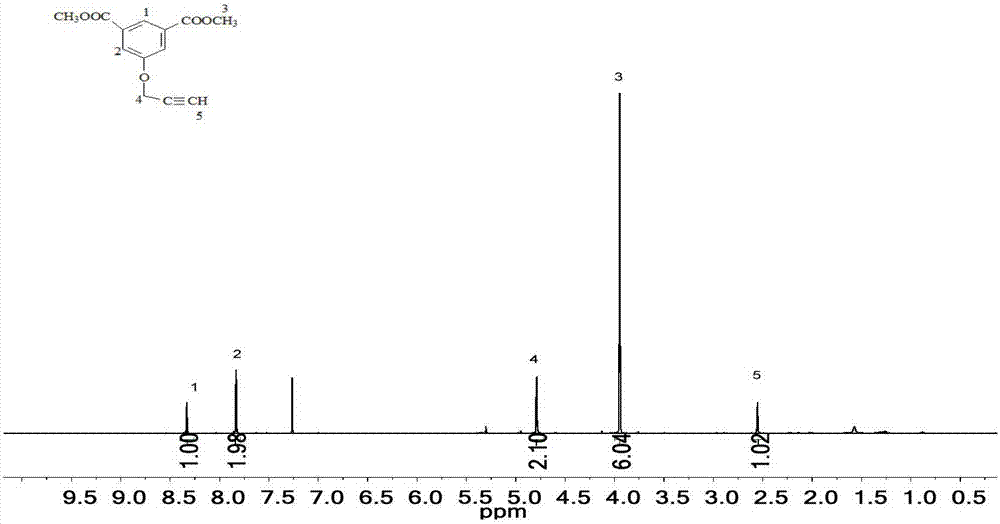

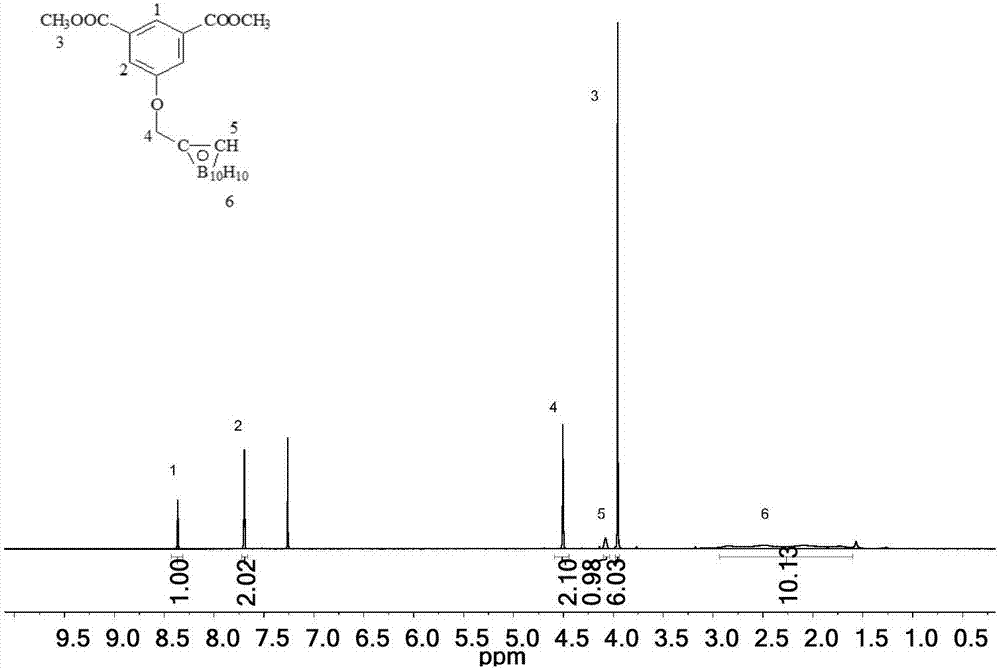

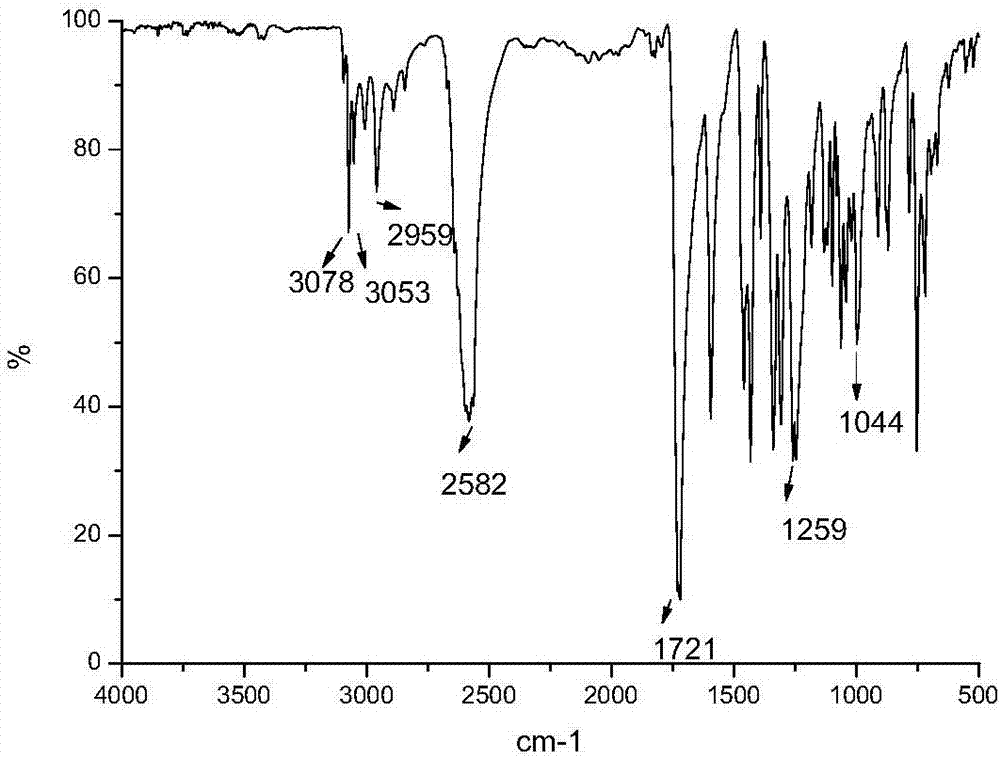

[0057] The preparation method of embodiment 1 5-(o-carborane-1'-methyleneoxy) dimethyl isophthalate (BDMI)

[0058] The route is as follows:

[0059]

[0060] In a three-necked flask, add 0.22mol 5-hydroxyisophthalic acid, 300ml methanol and 12ml concentrated sulfuric acid in sequence, and react under reflux in an oil bath at 70°C, monitor by TLC, and cool to room temperature naturally after the reaction. The reaction solution was slowly added to distilled water, and a large amount of white precipitates precipitated out. They were suction filtered and vacuum-dried to obtain a white powder with a yield of 96.8%. The product was methyl 5-hydroxyisophthalate with a melting point of 169°C.

[0061] In the three-necked flask, 0.22mol dimethyl 5-hydroxyisophthalate, 0.48mol anhydrous potassium carbonate and solvent DMF were added in sequence. Oil bath at 60°C, stirred for 1 hour, cooled to room temperature, slowly added dropwise 0.24mol 3-bromopropyne, kept at 25°C for reaction,...

Embodiment 2

[0064] The boron-containing organic hybrid polyester B-PET synthetic method adopts the transesterification method, and the specific steps include:

[0065] A. by the proportioning amount of table 1, dimethyl terephthalate, ethylene glycol, 5-(ortho-carborane-1 '-methyleneoxy) dimethyl isophthalate (embodiment 1 made), and catalyzer zinc acetate 0.01g is dropped in the reactor of 1L, logical nitrogen protection, heat up;

[0066] B. After heating up to 190°C, start stirring, control the temperature at 185°C-190°C, and react for 3 hours;

[0067] C. Raise the temperature to 280°C, stop nitrogen flow, vacuumize, and keep for 30 minutes;

[0068] D. Vacuumize to 133Pa, keep warm at 280℃~285℃, and react for 3h;

[0069] E. Stop the reaction, feed nitrogen gas under normal pressure, open the reaction kettle, slowly pour the polyester melt into distilled water to discharge while hot, and dry in vacuum to obtain boron-containing organic hybrid polyester B-PET.

[0070] F. Cut boron...

Embodiment 3-5

[0072] The operation steps are the same as in Example 1, except that the ratio of raw materials is different. The products prepared in Examples 2-5 are marked as B-PET-1, B-PET-2, B-PET-3, and B-PET-4. The ratio of raw materials is shown in Table 1.

[0073] Table 1 Synthesis of boron-containing organic hybrid polyester (B-PET) raw material components and mass ratio

[0074]

[0075] The physical and chemical properties and tensile strength tests of the spun fibers were carried out. See Table 2 and Table 3 for the performance data of boron-containing organic hybrid polyester B-PET. For the tensile stress-strain relationship of fiber monofilament, see figure 1. As a comparison, the corresponding parameters of polyester polyester (PET) were tested.

[0076] Table 2 Properties of boron-containing organic hybrid polyester B-PET

[0077]

[0078]

[0079] It can be determined from the intrinsic viscosity and molecular weight that the values of n and m in the molecu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com