A kind of anti-radiation stainless steel plate and its preparation method and application

A stainless steel, anti-radiation technology, applied in the field of anti-radiation materials, can solve the problems of environmental pollution, material cracking, waste of resources, etc., to achieve the effect of improving the ability, avoiding cracking, and increasing the boron content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

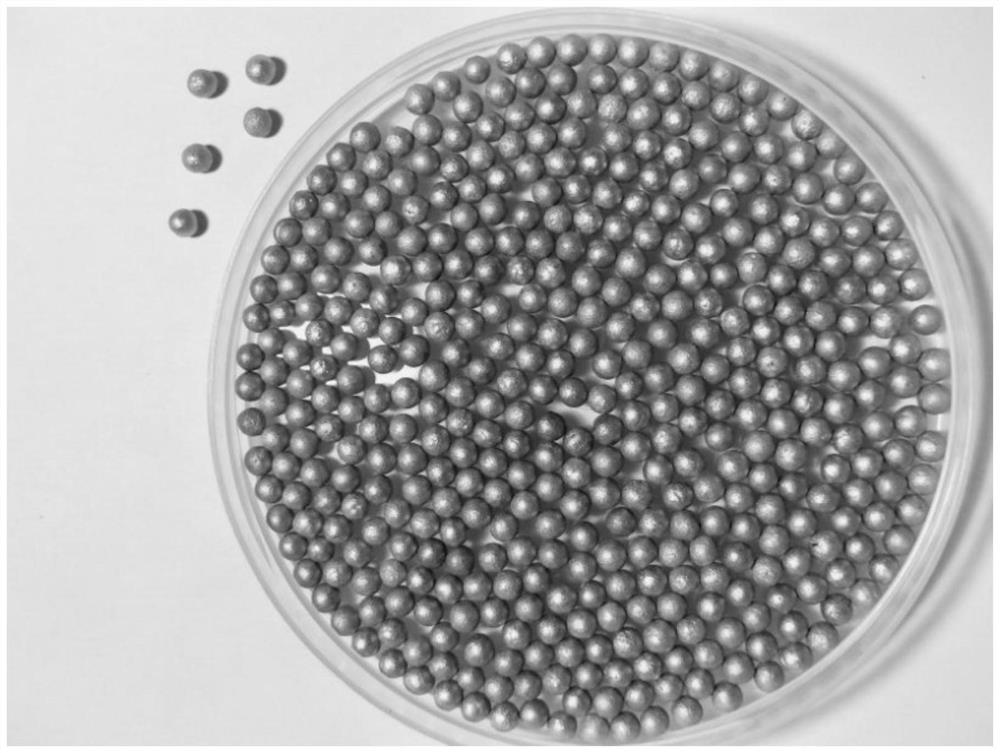

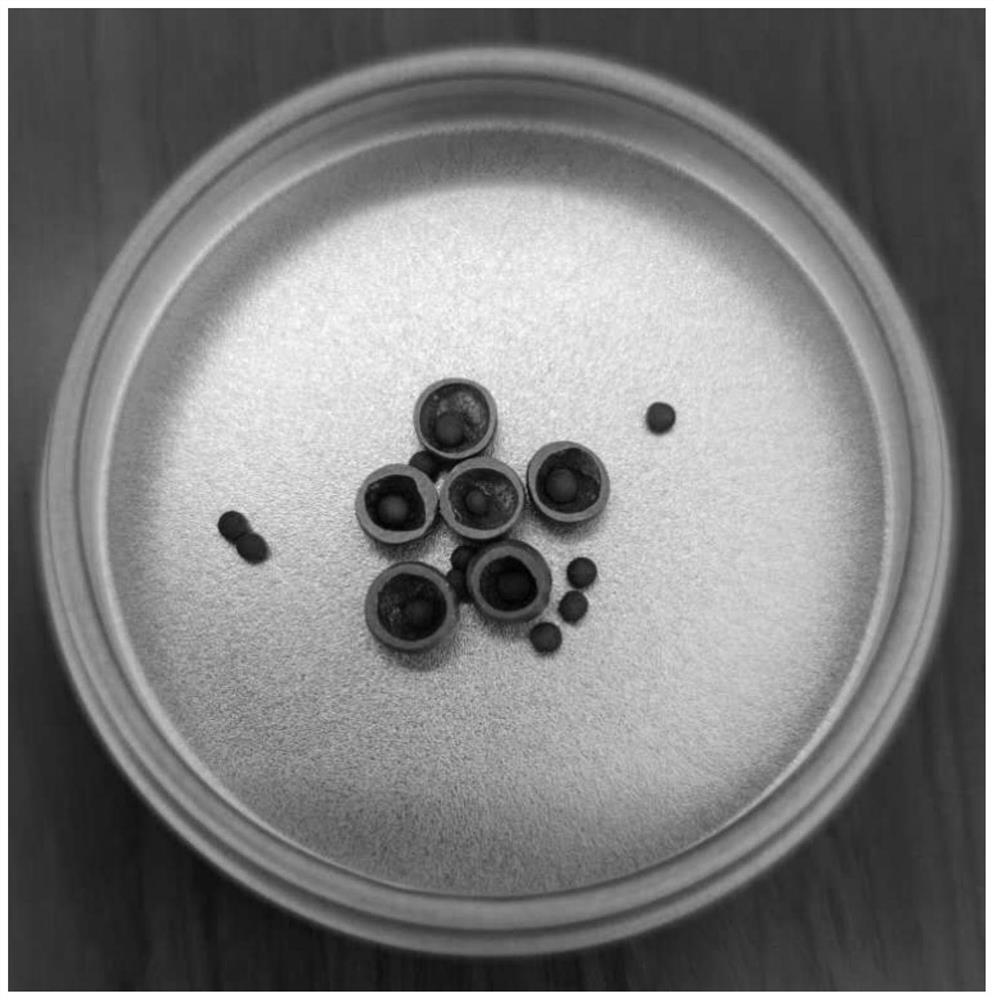

[0031] S1. Preparation of composite balls

[0032] The boron carbide is spheroidized, and then the hydrophilic modified polystyrene resin powder is mixed with the prepared boron carbide spheres, so that the polystyrene resin powder is wrapped on the surface of the boron carbide spheres. The volume of boron carbide is the same as that of boron carbide, and then the obtained spherical particles are put into a mixture of tungsten alloy powder (wherein, by mass ratio, tungsten: (iron+copper)=90wt%:10wt%) and bonding molding agent phenolic resin Roll forming on the powder to obtain a raw embryo, which is transferred to a muffle furnace for physical degreasing (heating from room temperature to 200 °C at a heating rate of 1 °C / min and then holding for 6h), physicochemical degreasing (at a heating rate of 1 °C / min) The heating rate was increased from 200 °C to 350 °C and then held for 3 hours), the shell was solidified (the temperature was increased from 350 °C to 900 °C at a heating ...

Embodiment 2

[0036] S1. Preparation of composite balls

[0037] The boron carbide is spheroidized, and then the hydrophilic modified polystyrene resin powder is mixed with the prepared boron carbide spheres, so that the polystyrene resin powder is wrapped on the surface of the boron carbide spheres. The volume is the same as that of boron carbide, and then the obtained spherical particles are put into a mixture of tungsten alloy powder (wherein, in terms of mass ratio, tungsten: (iron+copper)=95wt%:5wt%) and bonding molding agent phenolic resin Roll forming on the powder to obtain a raw embryo, which is transferred to a muffle furnace for physical degreasing (heating from room temperature to 200 °C at a heating rate of 1 °C / min and then holding for 6h), physicochemical degreasing (at a heating rate of 1 °C / min) The heating rate was increased from 200 °C to 350 °C and then held for 3 hours), the shell was solidified (the temperature was increased from 350 °C to 900 °C at a heating rate of 1...

Embodiment 3

[0041] S1. Preparation of composite balls

[0042]The boron carbide is spheroidized, and then the hydrophilic modified polystyrene resin powder is mixed with the prepared boron carbide spheres, so that the polystyrene resin powder is wrapped on the surface of the boron carbide spheres. The volume is the same as that of boron carbide, and then the obtained spherical particles are put into a mixture of tungsten alloy powder (wherein, in terms of mass ratio, tungsten: (iron+copper)=95wt%:5wt%) and bonding molding agent phenolic resin Roll forming on the powder to obtain a raw embryo, which is transferred to a muffle furnace for physical degreasing (heating from room temperature to 200 °C at a heating rate of 1 °C / min and then holding for 6h), physicochemical degreasing (at a heating rate of 1 °C / min) The heating rate was increased from 200 °C to 350 °C and then held for 3 hours), the shell was solidified (the temperature was increased from 350 °C to 900 °C at a heating rate of 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com