Irradiation preparation of geothermal floor substrate and its processing method

A technology of geothermal flooring and processing methods, which is applied to wood processing equipment, manufacturing tools, wood treatment, etc., can solve the problems of unenvironmental protection of products and processes, long wood manufacturing cycle, and easy occurrence of formaldehyde, etc., so as to save the use time of instruments and shorten the production time. The effect of short processing cycle and operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1: the processing method of Eucalyptus meranti modified floor substrate

[0071] According to the following components by weight percentage, the mixture is configured into a mixed solution, which is the impregnation solution:

[0072] Hydroxyethyl methacrylate 15%, methyl methacrylate 15%, ethyl methacrylate 10%, butyl methacrylate 10%, glycidyl methacrylate 20%, polyethylene glycol (PEG400) 20 %, ethylene glycol dimethacrylate 9%, trimethylolpropane triacrylate 1%.

[0073] 1. A batch of eucalyptus wood blocks. The length of the wood blocks is 300-800mm, the thickness is 20-80mm, and the width is 70mm. Dry them to a moisture content of 9%. Separated by a gap of 1cm, placed in a sealed jar;

[0074] 2. Vacuumize, and keep it for 15 minutes when the vacuum degree reaches 0.08Mpa;

[0075] 3. Open the valve and suck the prepared organic impregnating liquid into the sealed tank, control the flow rate to 50L / min, until the liquid level of the impregnating liqu...

Embodiment 2

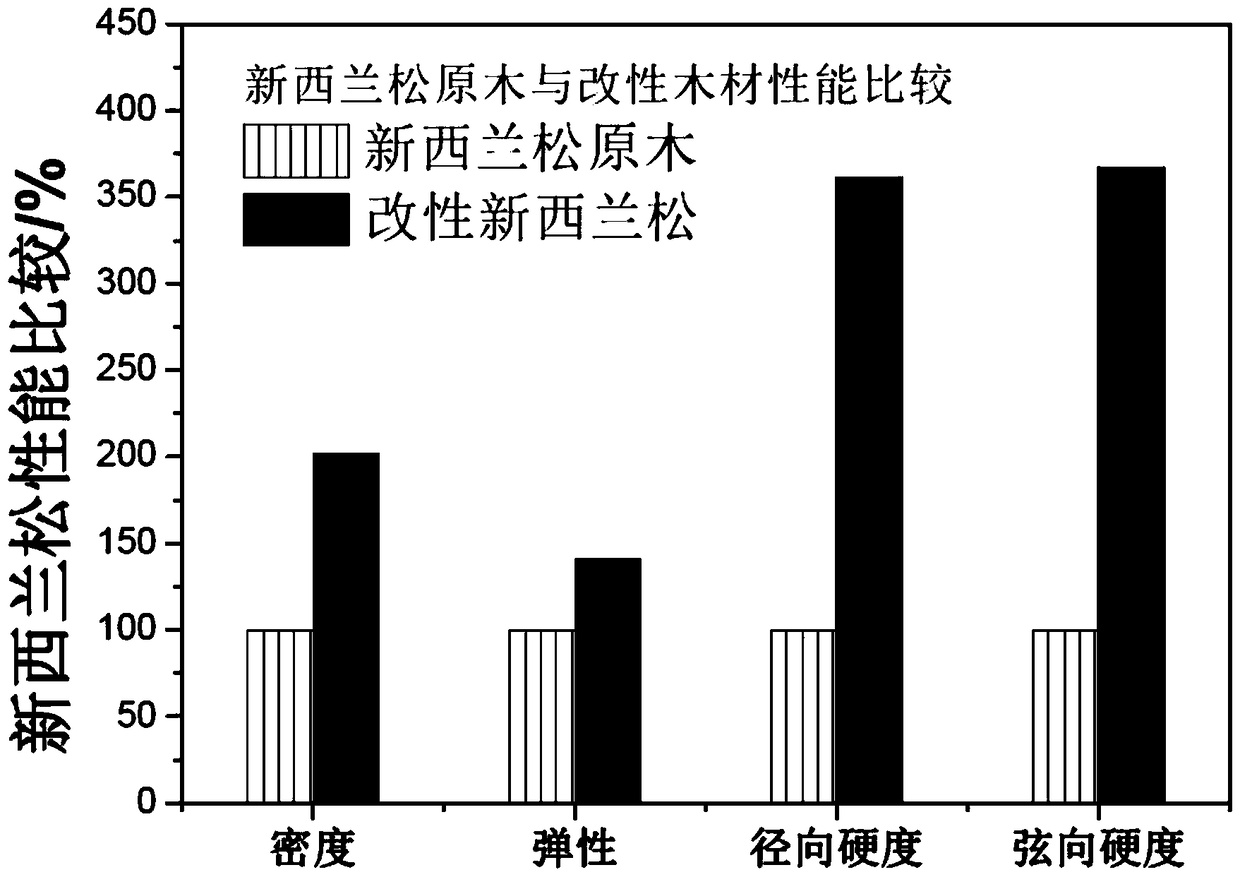

[0090] Embodiment 2: the processing method of New Zealand pine modified floor substrate

[0091] According to the following components by weight percentage, the mixture is configured into a mixed solution, which is the impregnation solution:

[0092] 10% hydroxyethyl methacrylate, 20% methyl methacrylate, 10% ethyl methacrylate, 10% butyl methacrylate, 24% glycidyl methacrylate, polyethylene glycol (PEG400) 20 %, ethylene glycol dimethacrylate 5%, trimethylolpropane triacrylate 1%.

[0093] 1. A batch of New Zealand pine wood blocks. The length of the wood blocks is 300-800mm, the thickness is 20-80mm, and the width is 70mm. Dry them to a moisture content of 15%. The racks are separated by a 1cm gap and placed in a sealed tank;

[0094] 2. Vacuumize, and keep it for 20 minutes when the vacuum degree reaches 0.1Mpa;

[0095] 3. Open the valve and suck the prepared organic impregnating liquid into the sealed tank, control the flow rate to 50L / min, until the liquid level of th...

Embodiment 3

[0118] The processing method of the New Zealand pine modified floor base material is basically the same as in Example 2, and the different dipping solution is a mixed solution configured according to the following components in percentage by weight:

[0119] Hydroxyethyl methacrylate 20%, methyl methacrylate 20%, ethyl methacrylate 10%, glycidyl methacrylate 24%, polyethylene glycol (PEG400) 20%, ethylene dimethacrylate Alcohol ester 5%, trimethylolpropane triacrylate 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com