Method for simultaneous determination of multiple trace elements in iron ore

A technology of trace elements and iron ore, which is applied in the direction of measuring devices, material analysis by electromagnetic means, instruments, etc., can solve the problems of low detection limit and inability to measure at the same time, and achieves simple operation, good application effect, and shortened sample time. The effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

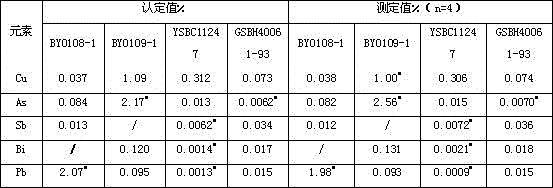

[0055] Weigh sandy tin raw ore BY0108-1; vein tin raw ore BY0109-1; steel standard samples YSBC11247, GSBH40061-93 and measure according to the above method, the results are shown in Table 1.

[0056] Table 1 standard sample measurement results

[0057]

[0058] Implementation instructions: because there are few iron ore standard samples with accurate assignment of antimony and bismuth, two steel standard samples are selected for verification in this case; the data with * numbers in the table are all beyond the measurement range of the present invention, and the measured values can only be Reference.

Embodiment 2

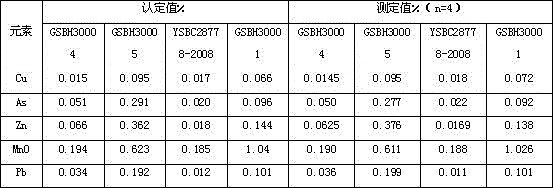

[0060] Weigh iron ore GSBH30004; iron ore GSBH30005; iron ore GSBH30001;

[0061] Table 2 standard sample measurement results

[0062]

Embodiment 3

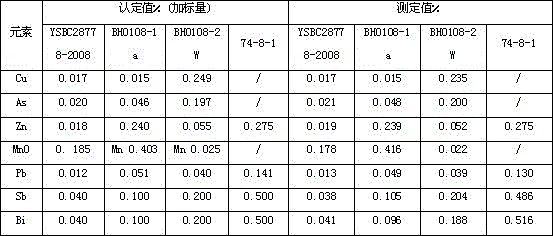

[0063] Embodiment 3: standard addition recovery

[0064] Weigh iron ore standard samples YSBC28778-2008, BH0108-1a, BH0108-2W, 74-8-1 that do not contain antimony and bismuth, and add antimony standard to make the content of antimony and bismuth respectively 0.040at%, 0.100at% , 0.200at%, 0.500at% were determined according to the above method, and the results are shown in Table 3.

[0065] Table 3 standard sample addition standard recovery measurement result

[0066]

[0067] From the data in the above table, it can be calculated that the recovery rates of antimony and bismuth are both 94% to 105%, and the determination results are accurate, meeting the requirements for the determination of arsenic, antimony, bismuth, lead, manganese, copper and zinc in iron ore. Require.

[0068] Therefore, the present invention can quickly and accurately measure the contents of arsenic, antimony, bismuth, lead, manganese, copper and zinc in iron ore by adopting microwave digestion-ICP-M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com