Process for reducing reaction of directional solidification titanium-aluminum alloy castings and casting mold coatings

A technology of directional solidification, titanium-aluminum alloy, applied in self-solidification, crystal growth, single crystal growth, etc., can solve problems such as low drawing rate, improve surface quality and dimensional accuracy, reduce internal pollutants, and interface reaction Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A process for reducing reaction of directionally solidified titanium-aluminum alloy castings with mold coatings.

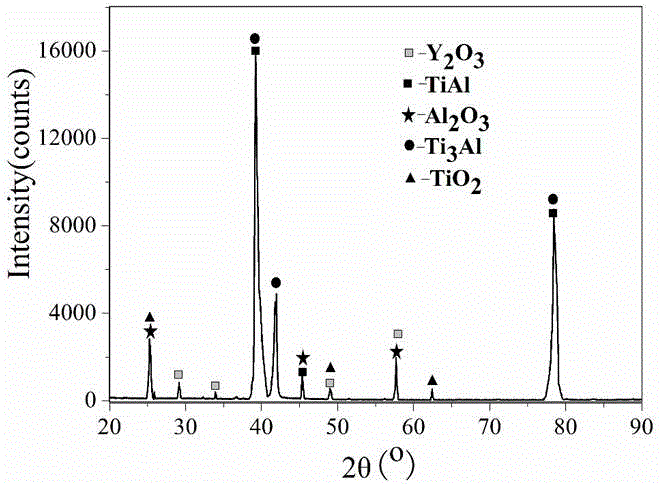

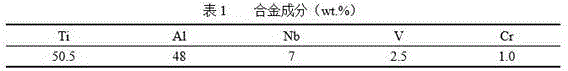

[0019] (1) The sample is smelted, and the master ingot for the test is prepared in a vacuum induction melting furnace. The alloy composition is shown in Table 1. Before heating, preheat the graphite mold to 200°C and keep it warm for 1 hour. After the heating is completed, quickly cool the cast state and take samples;

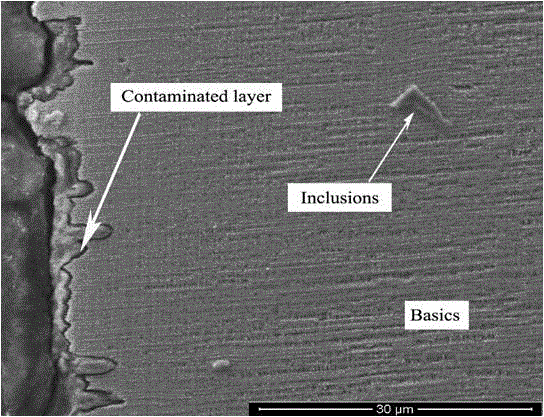

[0020] (2) A round rod with a diameter of 6 mm and a length of 100 mm was cut from the above alloy ingot as a directional solidification sample. Grind the surface scale, ultrasonically clean with acetone and dry at 120°C for one hour;

[0021] (3) Put the sample into Al 2 o 3 (Inner diameter is 6mm, outer diameter is 8mm) in the mold, fixed in the directional solidification furnace, close the equipment and start vacuuming, the vacuum degree of the furnace chamber is required to reach 5×10 -3 Pa, when heated to 500°C, argon is introduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com