Laser machining equipment

A laser processing and equipment technology, which is applied in the field of laser processing equipment for processing light guide plates, can solve the problems of poor light guide effect, low production efficiency, and long processing time, so as to improve processing quality and processing accuracy, facilitate operation, and process Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

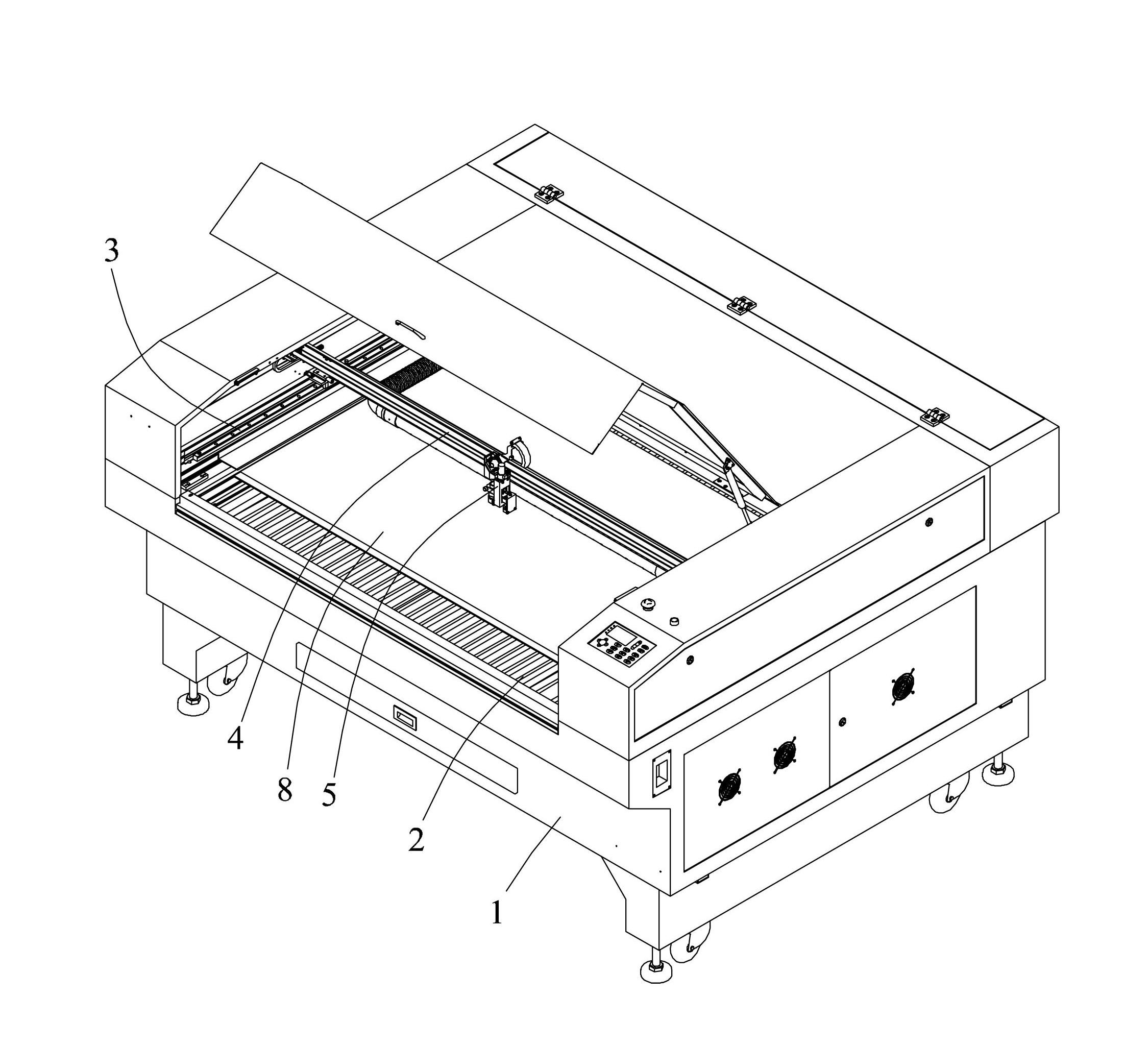

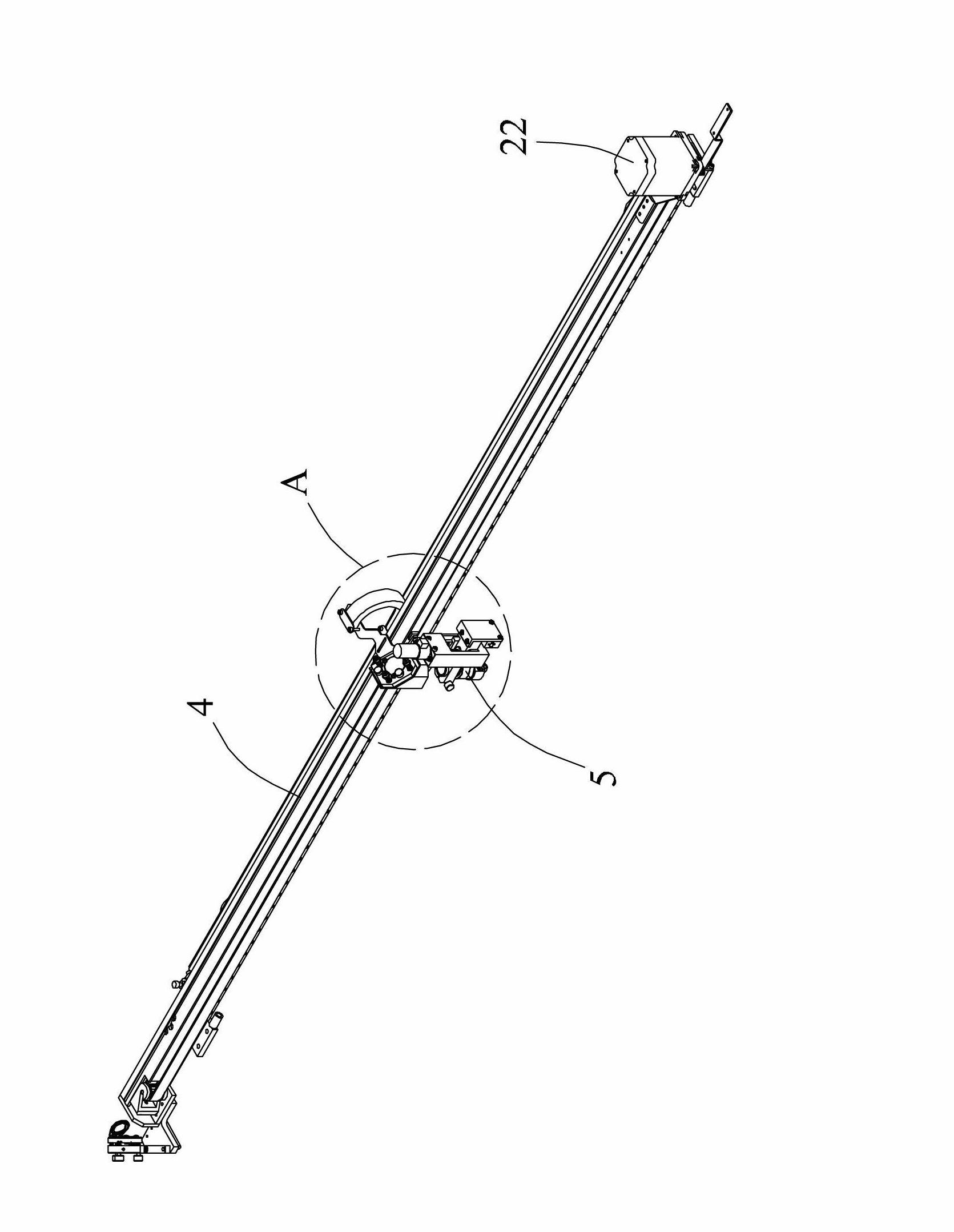

[0028] Such as Figure 1 to Figure 11 Shown is a preferred embodiment of the laser processing apparatus of the present invention.

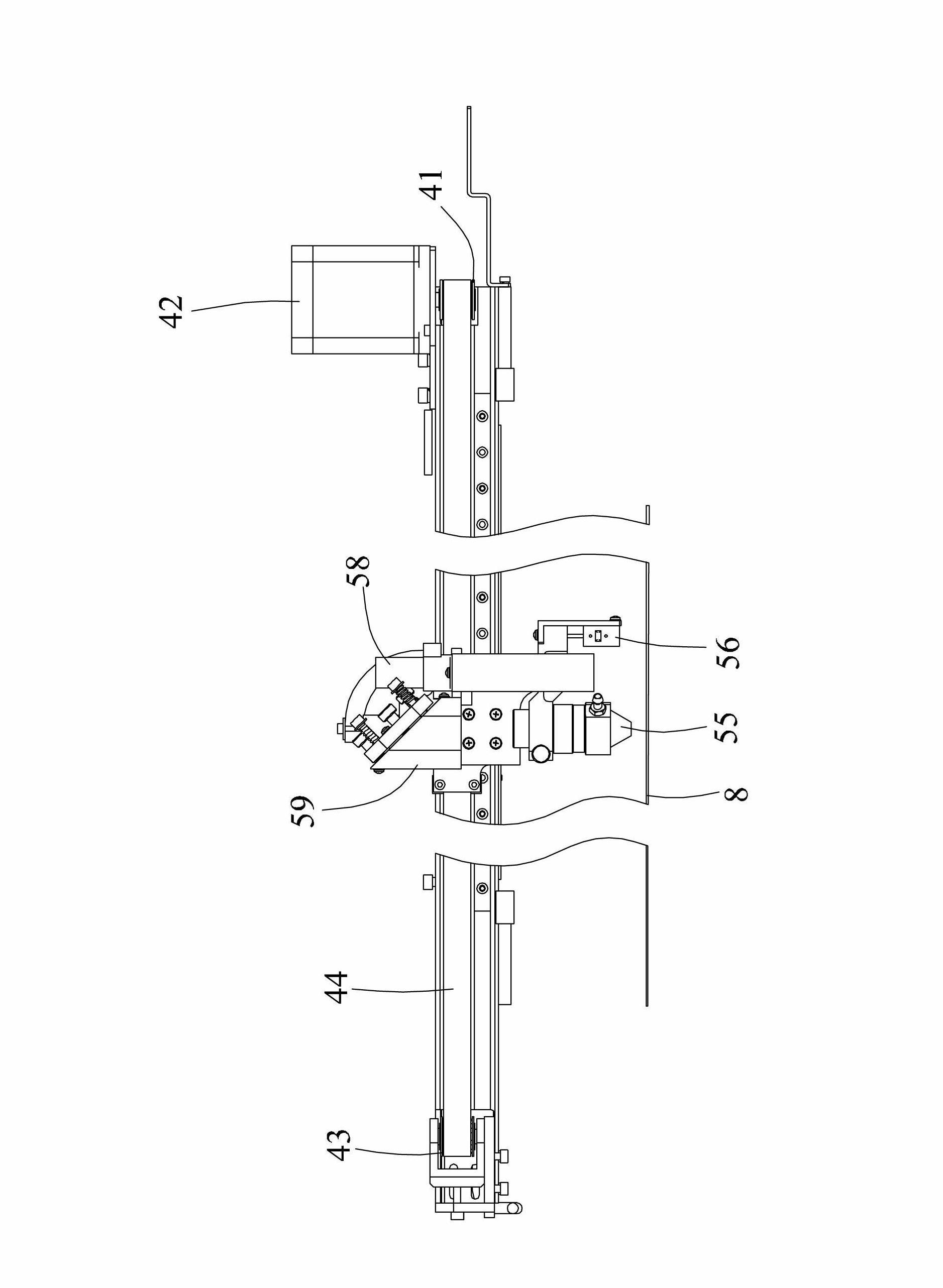

[0029] The laser processing equipment includes a frame 1, a workbench 2, a pair of guide rail beams 3, a crossbeam 4 and a laser cutting head 5. The left and right sides of the beam 4 are respectively installed on the pair of guide rail beams 3 and can move back and forth along the pair of guide rail beams 3. The laser cutting head 5 is installed on the beam 4 and can move along the beam 4 Moving left and right, the laser cutting head 5 includes a mounting block 51, a linear guide rail 52, a slide block 53, a focusing tube fixing plate 54, a focusing tube 55, a focus sensor 56, a motor fixing plate 57, a linear motor 58 and a mirror holder 59. The laser cutting head 5 is installed on the beam 4 through the mounting block 51, the linear guide rail 52 is vertically fixed on the mounting block 51, and the slider 53 is slidably installed on the linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com