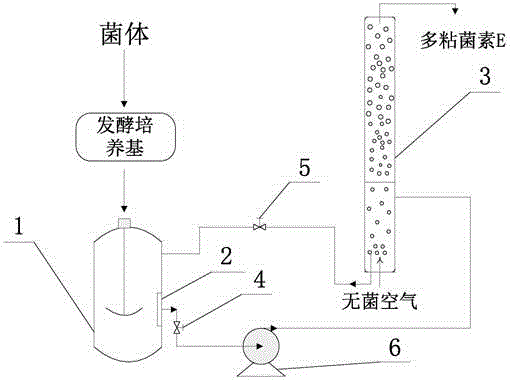

Method for producing polymyxin E through fermentation and foam separation coupling

A technology of foam separation and polymyxin, applied in the field of bioengineering, can solve the problems of low total potency of polymyxin E, lower raw material utilization rate, lower enrichment ratio, etc. churn, conversion-boosting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The Bacillus polymyxa strain obtained from the frozen glycerin tube was inoculated into a slant medium for activation, and cultured at 30°C for 72 hours. The activated bacterial liquid was inoculated into the seed culture medium and cultured at 32°C for 24 hours to obtain the seed liquid (the same in the following examples). The seed liquid was inoculated into a 1.8L fermenter (100) that was sterilized by high temperature at 10% of the inoculum. The fermenter (100) was filled with 1.2L, the culture temperature was 30°C, and the stirring speed was 200r / min. The ventilation volume is 150mL / min. The composition of the fermentation medium is: glucose 20g / L, peptone 10g / L, sodium chloride 1g / L, potassium dihydrogen phosphate 0.1g / L, ammonium sulfate 10g / L, ferrous sulfate 0.1g / L, and ammonia to adjust the initial pH 7,115-121℃ high pressure steam sterilization for 15-30min. After 33 hours of fermentation under these conditions, the detected bacterial content reached 4.19g / L...

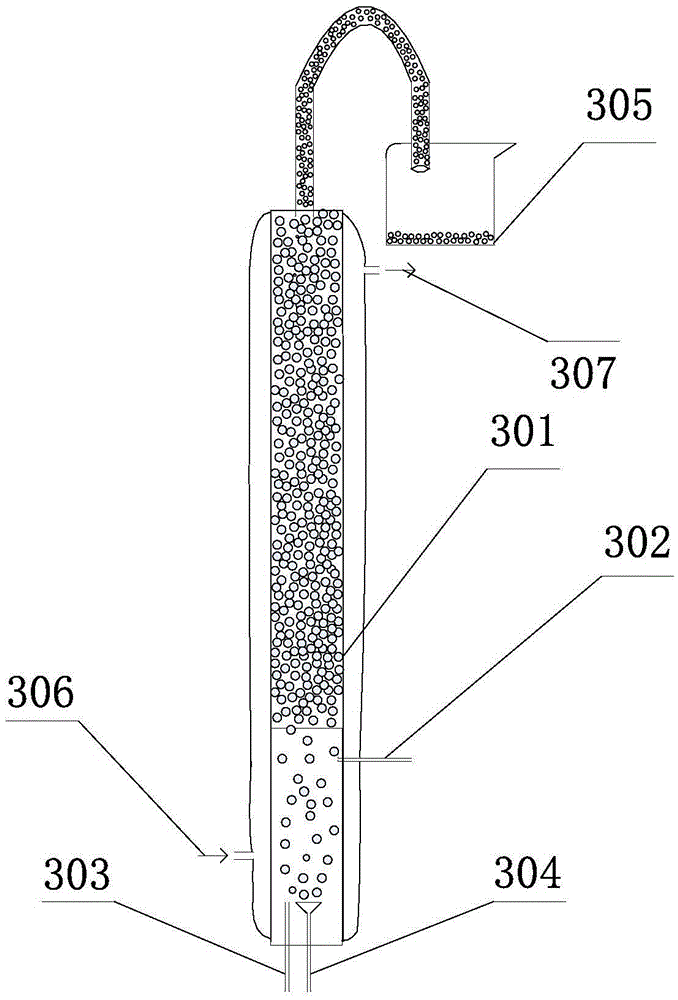

Embodiment 2

[0049] The seed liquid was inoculated into a 1.8L fermenter (100) that was sterilized by high temperature at a 10% inoculum. The fermenter (100) had a liquid volume of 1.4L, a culture temperature of 34°C, and a stirring speed of 300r / min. The ventilation volume is 200mL / min. The composition of the fermentation medium is: glucose 20g / L, peptone 10g / L, sodium chloride 1g / L, potassium dihydrogen phosphate 0.1g / L, ammonium sulfate 10g / L, ferrous sulfate 0.1g / L, and ammonia to adjust the initial pH 7,115-121℃ high pressure steam sterilization for 15-30min. After 36 hours of fermentation under these conditions, the detected bacterial content reached 4.01g / L, and the polymyxin E content reached 4712U / mL. At this time, open the discharge valve (4), the feed peristaltic pump (6) and the digital display constant temperature water bath device and constant temperature water bath inlet (306) and constant temperature water bath outlet (307) on the outside of the separation tower to pass the...

Embodiment 3

[0051] The seed liquid was inoculated into a 1.8L fermenter (100) that was sterilized by high temperature at a rate of 10%. The fermenter (100) had a liquid volume of 1.3L, the culture temperature was 32°C, and the stirring speed was 250r / min. The ventilation volume is 200mL / min. The composition of the fermentation medium is: glucose 20g / L, peptone 10g / L, sodium chloride 1g / L, potassium dihydrogen phosphate 0.1g / L, ammonium sulfate 10g / L, ferrous sulfate 0.1g / L, and ammonia to adjust the initial pH 7,115-121℃ high pressure steam sterilization for 15-30min. After 33 hours of fermentation under these conditions, the detected bacterial content reached 4.24g / L and the polymyxin E content reached 4901U / mL. At this time, open the discharge valve (4), the feed peristaltic pump (6) and the digital display constant temperature water bath device and constant temperature water bath inlet (306) and constant temperature water bath outlet (307) on the outside of the separation tower to pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com