Separation method for acetophenone and 1-phenylethanol

A separation method and technology of acetophenone, applied in chemical instruments and methods, separation/purification of hydroxyl compounds, separation/purification of carbonyl compounds, etc., can solve the problems of unsuitable industrial scale production, long operation cycle and low product purity and other issues, to achieve the effect of high product recovery rate, less three wastes, and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

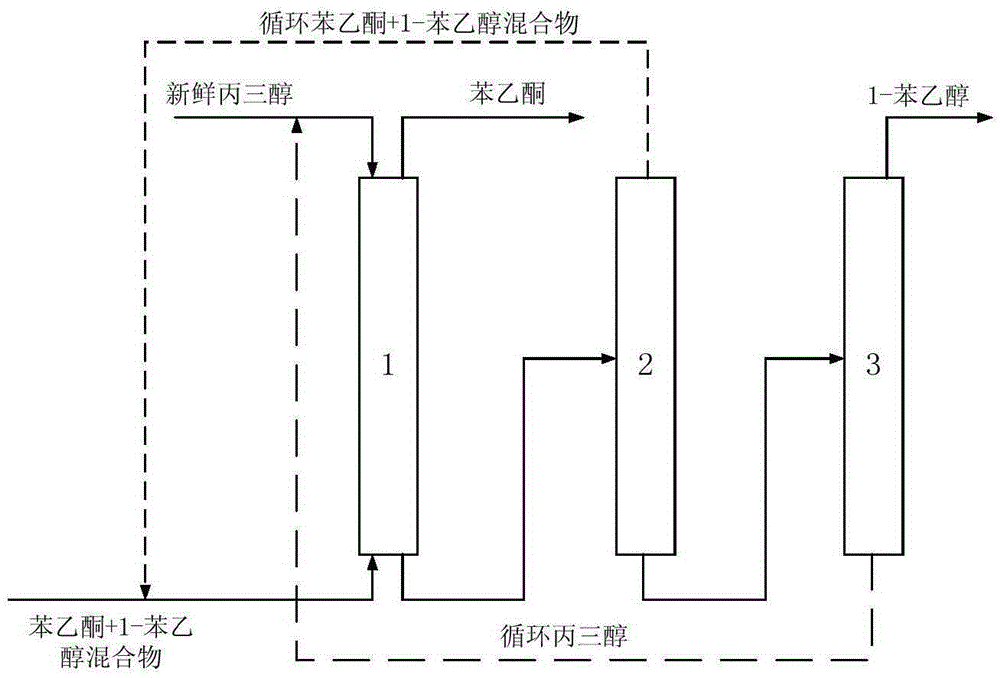

[0039] A kind of separation method of acetophenone and 1-phenylethanol, such as figure 1 shown, including the following steps:

[0040] (1) the mass percent concentration of acetophenone is that the acetophenone of 87.2% and the 1-phenylethanol mixture are squeezed into the bottom of extraction tower 1, and in extraction tower 1 with the extraction agent glycerin that adds from the top of extraction tower 1 Countercurrent contacting is carried out extraction, and the product acetophenone (purity of sampling analysis is 98.2%, recovery rate of acetophenone 99.99%) is obtained at the top of extraction tower 1, and the mixture of acetophenone, 1-phenylethanol and glycerol is obtained at the bottom of the tower, and extraction The operating temperature of the tower is 90.0°C, the pressure is 1MPa, and the molar flow ratio of the mixture of glycerol, acetophenone and 1-phenylethanol is 0.915:1;

[0041](2) the mixture at the bottom of the tower that step (1) obtains is put into re...

Embodiment 2

[0044] A kind of separation method of acetophenone and 1-phenylethanol, such as figure 1 shown, including the following steps:

[0045] (1) the mass percent concentration of acetophenone is that the acetophenone of 41.6% and 1-phenylethanol mixture are squeezed into the bottom of extraction tower 1, and in extraction tower 1 with the extraction agent glycerol that adds from the top of extraction tower 1 Countercurrent contact is carried out extraction, and the product acetophenone (purity of sampling analysis is 98.1%, recovery rate of acetophenone 99.92%) is obtained at the top of extraction tower 1, and the mixture of acetophenone, 1-phenylethyl alcohol and glycerol is obtained at the bottom of the tower, and extraction The operating temperature of the tower is 70.0°C, the pressure is 0.1MPa, and the molar flow ratio of the mixture of glycerol, acetophenone and 1-phenylethanol is 6:1;

[0046] (2) the tower bottom mixture that step (1) is obtained enters rectification in th...

Embodiment 3

[0049] A kind of separation method of acetophenone and 1-phenylethanol, such as figure 1 shown, including the following steps:

[0050] (1) the mass percent concentration of acetophenone is that the acetophenone of 56.4% and the 1-phenylethanol mixture are squeezed into the bottom of extraction tower 1, and in extraction tower 1 with the extraction agent glycerin that adds from the top of extraction tower 1 Countercurrent contact is carried out extraction, and the product acetophenone (purity of sampling analysis is 98.1%, recovery rate of acetophenone 99.96%) is obtained at the top of extraction tower 1, and the mixture of acetophenone, 1-phenylethyl alcohol and glycerol is obtained at the bottom of the tower, and extraction The operating temperature of the tower is 20.0°C, the pressure is 0.05MPa, and the molar flow ratio of glycerol, acetophenone and 1-phenylethanol mixture is 10:1;

[0051] (2) the tower bottom mixture that step (1) obtains is put into rectifying in the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com