Silicon carbide-based composite foam ceramics with multi-layer pore-reinforcement structure and preparation method thereof

A silicon carbide-based, composite foam technology is applied in the field of foam ceramics, which can solve the problems of complex process, large equipment investment, not taking into account the mechanical properties and thermal shock resistance of silicon carbide foam ceramics, and achieves simple, low-cost, low-cost technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

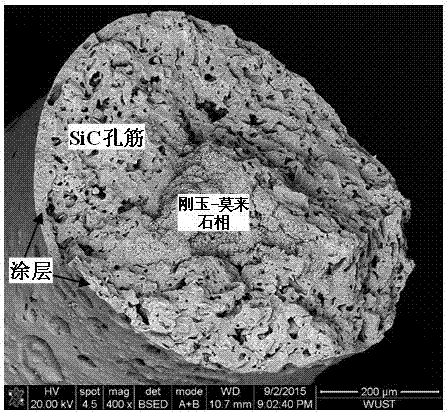

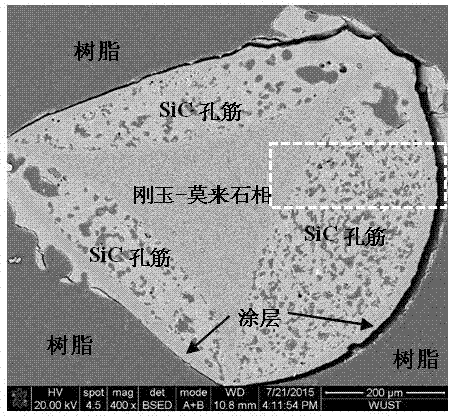

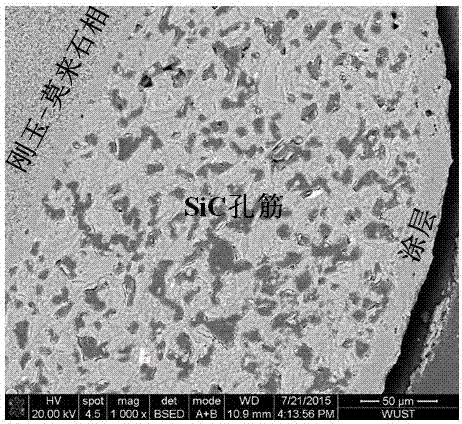

[0029] The invention discloses a silicon carbide-based composite foam ceramic with a multi-layer pore-reinforcement structure and a preparation method thereof. The steps of the preparation method are:

[0030] Step 1. Mix 70-80 parts by mass of silicon carbide, 13-20 parts by mass of alumina micropowder and 7-10 parts by mass of silicon micropowder to obtain mixed powder I; then add 0.5-2 parts by mass to mixed powder I Ammonium lignosulfonate, 0.1-0.5 parts by mass of polycarboxylate, 0.3-1 part by mass of carboxymethyl cellulose and 25-45 parts by mass of water were stirred for 30-60 minutes to prepare slurry I.

[0031] Step 2. Mix 80-94 parts of alumina micropowder with 6-20 parts of elemental silicon to obtain mixed powder II, and then add 0.3-1 part of polycarboxylate, 0.01-0.06 parts of polycarboxylate to mixed powder II. Parts by mass of absolute ethanol and 23-46 parts by mass of water, ball milled for 2-4 hours to obtain slurry II.

[0032] Step 3: Immerse the poly...

Embodiment 2

[0036] The invention discloses a silicon carbide-based composite foam ceramic with a multi-layer pore-reinforcement structure and a preparation method thereof. The preparation method shown in this embodiment is the same as in Example 1 except step 2.

[0037] Step 2, mix 65~70 parts of quality alumina micropowder with 30~35 parts of quality andalusite to obtain mixed powder II, then add 0.3~1 part of quality polycarboxylate, 0.01~0.06 Parts by mass of absolute ethanol and 23-46 parts by mass of water, ball milled for 2-4 hours to obtain slurry II.

[0038] The silicon carbide-based composite foam ceramics with multi-layer rib structure prepared in this example has been tested: the compressive strength at room temperature is 2.5-2.9 MPa; the number of water cooling cycles at 1100°C is 15-19 times; the multi-layer rib structure The SiC oxidation rate of silicon carbide-based composite foam ceramics is 3~5% after being oxidized at 1500℃ for 10 hours in air atmosphere.

Embodiment 3

[0040] The invention discloses a silicon carbide-based composite foam ceramic with a multi-layer pore-reinforcement structure and a preparation method thereof. The preparation method shown in this embodiment is the same as in Example 1 except step 2.

[0041] Step 2: Mix 70-75 parts of alumina micropowder with 20-30 parts of zircon to obtain mixed powder II, then add 0.3-1 part of polycarboxylate, 0.01- 0.06 parts by mass of absolute ethanol and 23 to 46 parts by mass of water were ball milled for 2 to 4 hours to obtain slurry II.

[0042] The silicon carbide-based composite foam ceramics with multi-layer rib structure prepared in this example has been tested: the compressive strength at room temperature is 2.5-2.8 MPa; the number of water cooling cycles at 1100°C is 15-19 times; the multi-layer rib structure The SiC oxidation rate of SiC-based composite foam ceramics is 2~5% after being oxidized at 1500℃ for 10 hours in air atmosphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com