Low cost titanium alloy and homogenization preparation method thereof

A titanium alloy, low-cost technology, applied in the field of casting titanium alloy, can solve the problems of uneven composition of ingots, reduction of alloy tensile strength, elongation and other properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

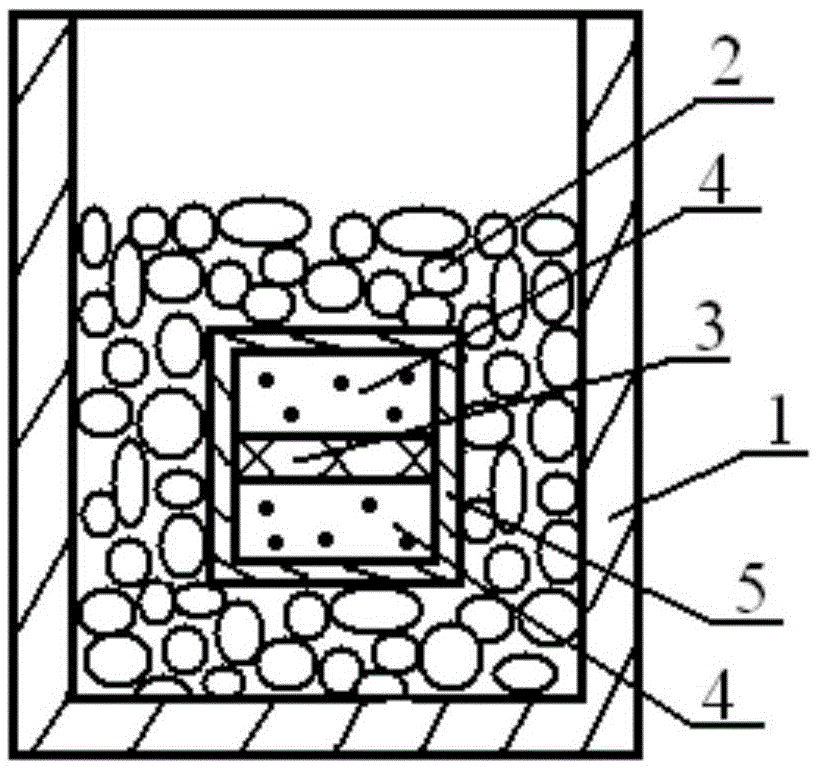

[0032] The present invention also provides a method for preparing a low-cost titanium alloy, comprising the following steps:

[0033] 1) Raw material ratio: Calculate the dosage ratio of titanium source compound, vanadium source compound, aluminum source compound, iron source compound and oxygen source compound according to the raw material components of titanium alloy;

[0034] 2) Placement of raw materials: put the titanium source compound into the water-cooled copper crucible induction shell solidification furnace 1 and place it well, and the distance between the titanium source compound and the top of the water-cooled copper crucible induction shell solidification furnace 1 is not less than the 1 / 4 of the height of the water-cooled copper crucible induction shell furnace 1, and then bury the aluminum source compound, vanadium source compound and oxygen source compound inside the titanium source compound;

[0035] 3) Melting and pouring: After evacuating the water-cooled copp...

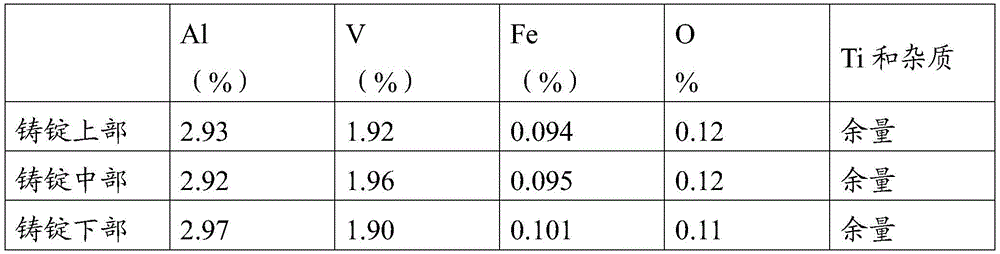

Embodiment 1

[0052] The quality of the low-cost titanium alloy ingot is 10 kg, and the composition is calculated by mass percentage: Al is 3.0%, V is 2.0%, Fe is 1.0%, O is 0.1%, and the rest is Ti and unavoidable impurities;

[0053] The homogeneous preparation method of the above-mentioned low-cost titanium alloy comprises the following steps:

[0054] 1) Prepare raw materials:

[0055] The Ti6Al4V recycled material 4 contains 99.2% of Ti6Al4V, 0.15% of Fe, and 0.10% of O; the sponge titanium 2 is 0-grade sponge titanium 2, which contains 99.6%, 0.10% of Fe, and 0.08% of O; 2 TiO in powder 3 2 The Fe content is 99%; the Fe content in the analysis of pure iron powder is 99%.

[0056] Calculate the Ti6Al4V recycled material 45040.30g according to the mass percentage of elements in the above-mentioned low-cost titanium alloy, TiO 2 Powder 316.63g, Fe powder 92.27g, titanium sponge 24850.80g.

[0057] (2) Place raw materials:

[0058] Put the titanium sponge 2 into the water-cooled copp...

Embodiment 2

[0068] The quality of the low-cost titanium alloy ingot is 20 kg, and the composition is calculated by mass percentage: Al is 4%, V is 2%, Fe is 1.5%, O is 0.15%, and the rest is Ti and unavoidable impurities;

[0069] The homogeneous preparation method of the above-mentioned low-cost titanium alloy comprises the following steps:

[0070] 1) Prepare raw materials:

[0071] The Ti6Al4V recycled material 4 contains 99.1% of Ti6Al4V, 0.20% of Fe, and 0.15% of O; the content of Al in the aluminum foil 5 is 99.5%; the sponge titanium 2 is a grade 1 sponge titanium, containing 99.6% of Ti and 0.10% of Fe, O is 0.08%; TiO 2 TiO in powder 3 2 The Fe content is 99%; the Fe content in the analysis of pure iron powder is 98%.

[0072] According to the mass percentage of elements in the above-mentioned low-cost titanium alloy, Ti6Al4V reclaimed material 410090.82g, aluminum foil 5201.00g, TiO 2 Powder 318.52g, Fe powder 277.34g, titanium sponge 29412.32g.

[0073] (2) Place raw mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com