Carbon nanometer field emission cathode and its preparation method and application

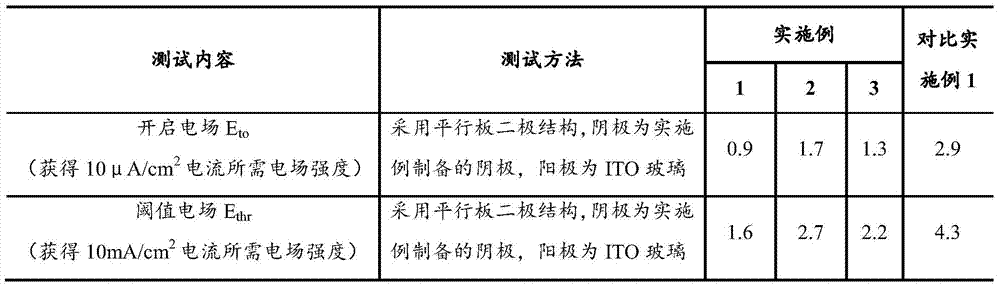

A field emission cathode and carbon nanotechnology, applied in the field of field emission, can solve the problems of few effective emission tips, poor emission stability, small emission current, etc., achieve excellent field emission performance, stable performance, and increase the effect of emission tips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

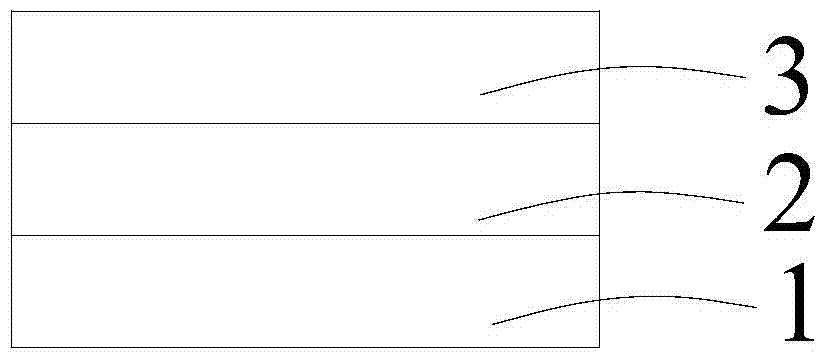

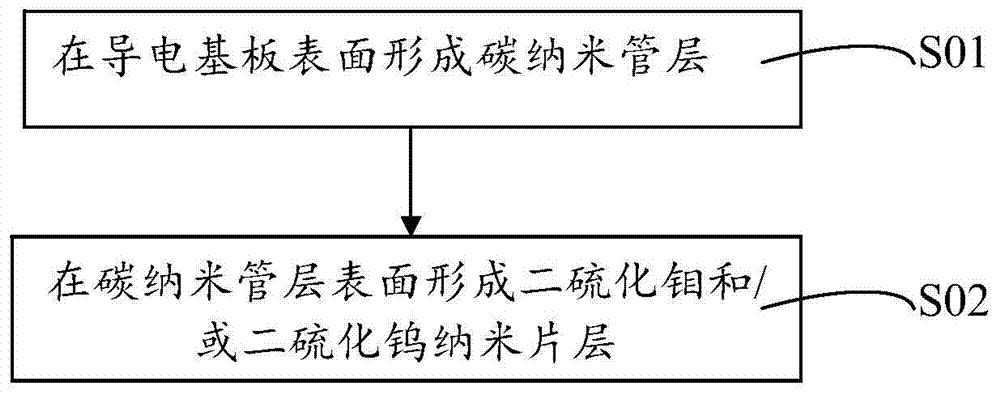

[0029] On the other hand, on the basis of the carbon nanometer field emission cathode of the embodiment of the present invention described above, the embodiment of the present invention also provides a preparation method of the carbon nanometer field emission cathode of the embodiment of the present invention. The preparation method of the carbon nanometer field emission cathode of the embodiment of the present invention is as follows figure 2 Therefore, see also figure 1 , its preparation method comprises the following steps:

[0030] S01. Forming a carbon nanotube layer 2 on the surface of the conductive substrate 1;

[0031]S02. Molybdenum disulfide and / or tungsten disulfide nanosheet layer 3 is formed on the surface of the carbon nanotube layer 2: Molybdenum disulfide and / or tungsten disulfide nanosheets are dispersed in an organic solvent to form a dispersion, and then the The dispersion liquid forms a molybdenum disulfide and / or tungsten disulfide nanosheet layer 3 on...

Embodiment 1

[0063] The embodiment of the present invention provides a carbon nanometer field emission cathode and a preparation method thereof, which include a conductive substrate 1 / carbon nanotube layer 2 / molybdenum disulfide nanosheet layer 3 sequentially stacked and combined. Among them, the conductive substrate 1 is made of copper sheet; the carbon nanotubes in the carbon nanotube layer 2 are multi-walled carbon nanotubes with a diameter of 2-8nm and a length of 10-15μm; the thickness of the molybdenum disulfide nanosheets is 1nm , the lateral dimension is 100-300nm,

[0064] Its preparation method is as follows:

[0065] S11. Provide conductive substrate: copper sheet

[0066] S12. Preparation of carbon nanotube film 2 by electrophoretic deposition method:

[0067] S121. Combining carbon nanotubes with soluble metal inorganic salt MgCl 2 Add in ethanol, ultrasonically disperse for 1 to 3 hours to obtain a uniform and stable carbon nanotube electrophoresis solution, the concentrat...

Embodiment 2

[0072] The embodiment of the present invention provides a carbon nanometer field emission cathode and a preparation method thereof, which comprises sequentially stacking and bonding a conductive substrate 1 / carbon nanotube layer 2 / tungsten disulfide nanosheet layer 3. Wherein, the conductive substrate 1 material is a stainless steel sheet; the carbon nanotubes in the carbon nanotube layer 2 are single-walled carbon nanotubes with a diameter of 1-2 nm and a length of 10-20 μm; the thickness of the tungsten disulfide nanosheets is 2 -4nm with a lateral dimension of 100-300nm.

[0073] Its preparation method is as follows:

[0074] S21. Provide conductive substrate: silicon wafer

[0075]S22. Preparation of carbon nanotube film 2 by electrophoretic deposition method:

[0076] S221. Combining carbon nanotubes with soluble metal inorganic salt Al(NO 3 ) 2 Add in ethanol, ultrasonically disperse for 1 to 3 hours to obtain a uniform and stable carbon nanotube electrophoresis solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com