A double-gate control type cold cathode electron gun and its preparation method

A dual-gate control, electron gun technology, applied in the direction of cold cathode, discharge tube electron gun, electron/ion gun of transit time type electron tube, etc. life and other issues, to achieve the effect of weakening the electrostatic shielding effect, avoiding processing burrs, and achieving good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

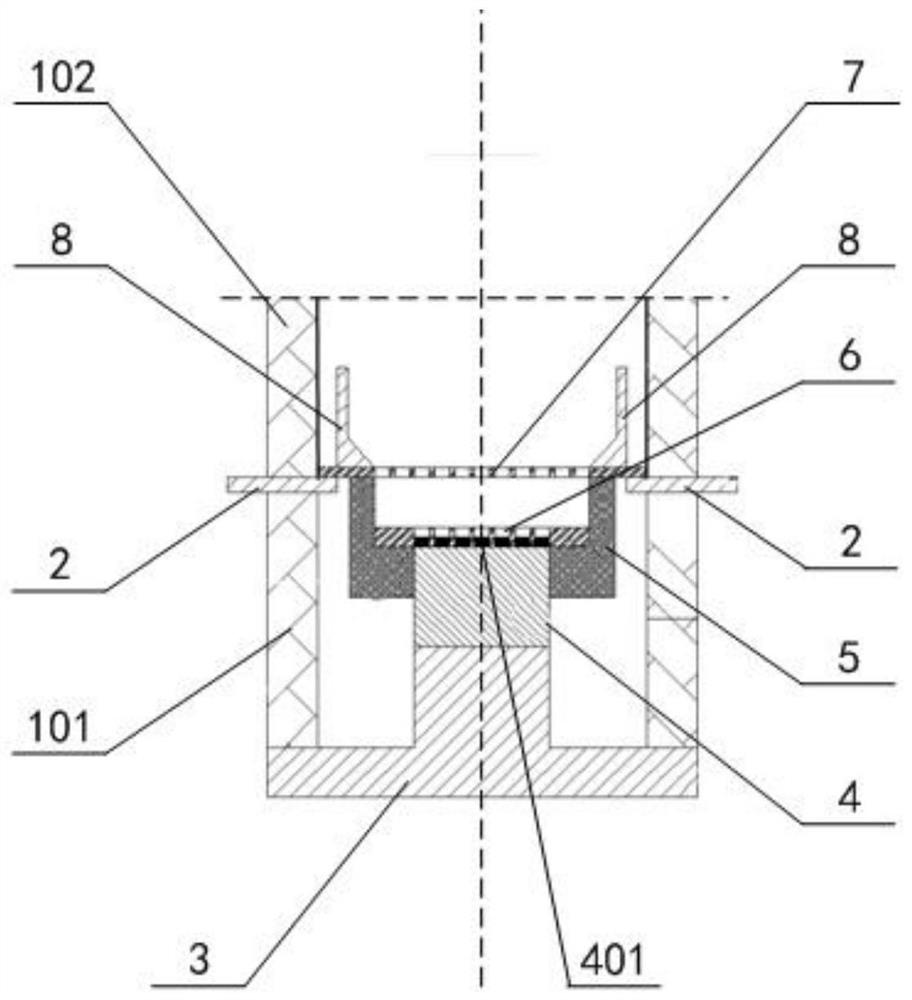

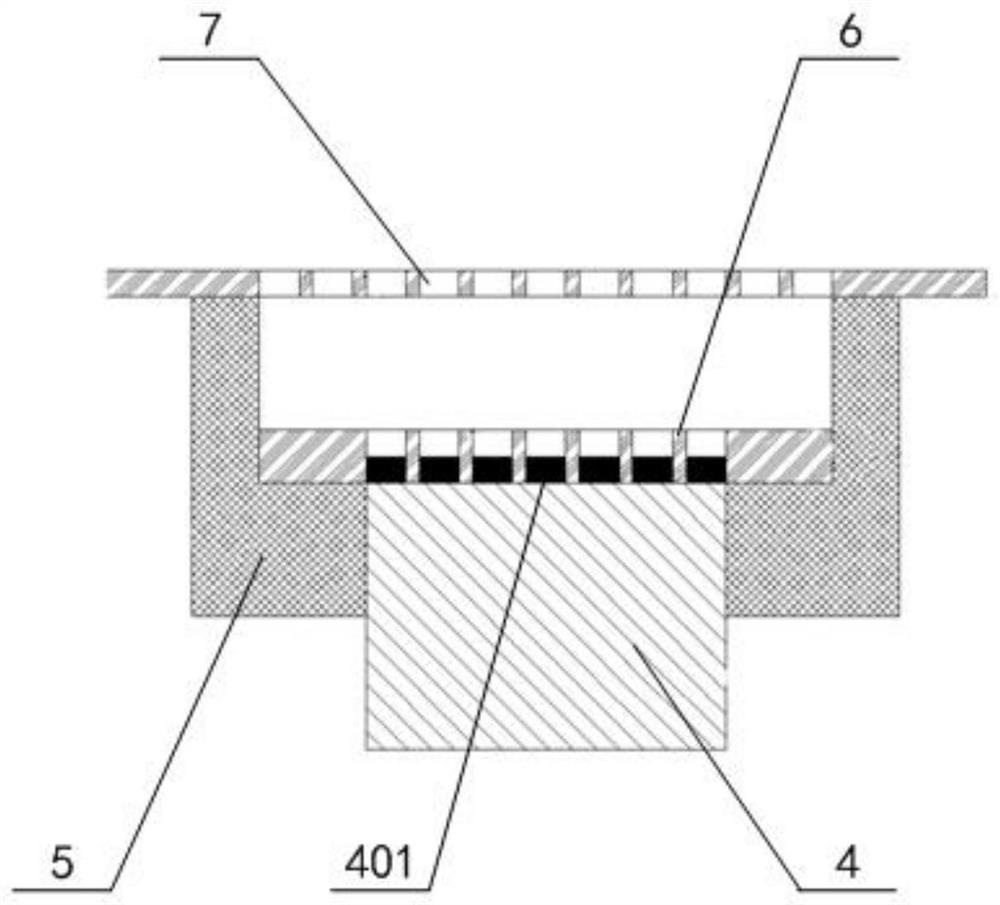

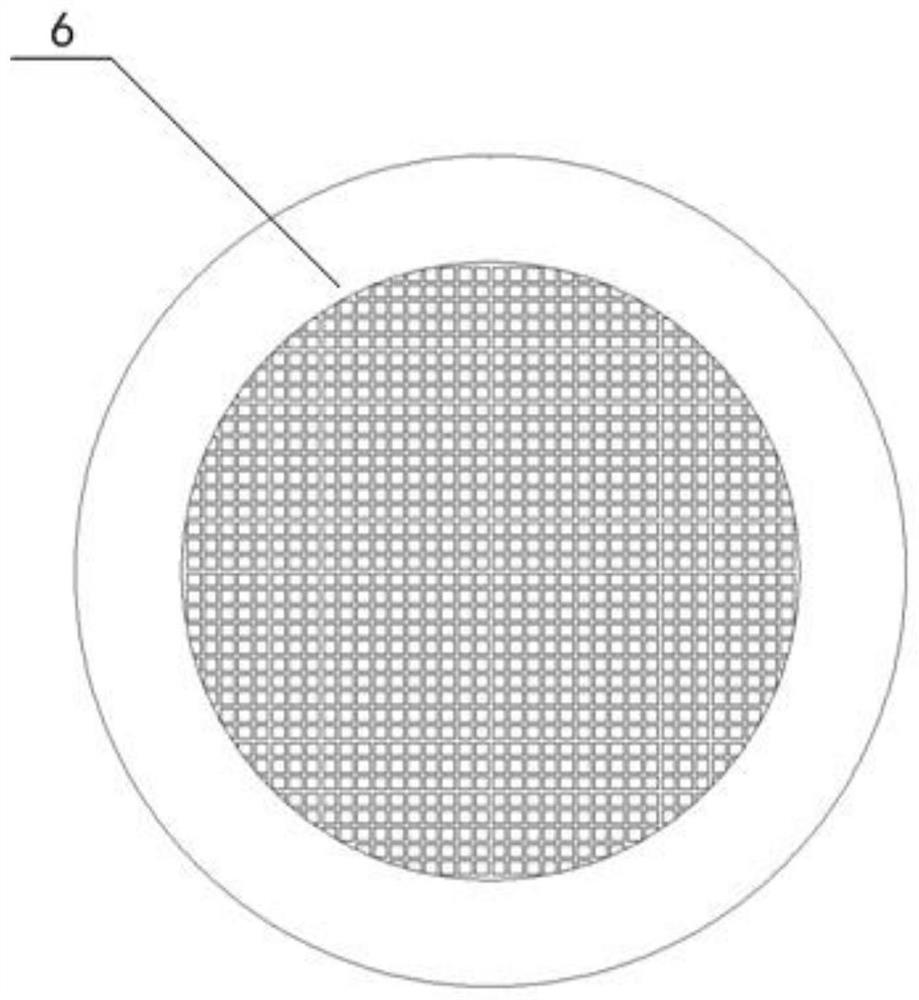

[0049] Such as Figure 1~6 As shown, the double grid controlled cold cathode electron gun provided in this embodiment includes an electron gun insulating shell, an annular electrode piece 2, a cathode base 3, a cathode substrate 4, a tubular insulating connector 5, a cathode grid 6, an outer Set the grid 7 and the tube-type focusing pole 8, wherein the inside of the electron gun insulating shell is vacuum and is composed of a lower sleeve 101 and an upper sleeve 102, and the annular electrode sheet 2 is arranged on the lower sleeve 101 Between the upper sleeve 102, the cathode base 3 has a two-stage stepped column structure and seals the lower port of the lower sleeve 101, and the cathode substrate 4 has a column structure and has a The cold cathode material layer 401, the inner cavity of the tubular insulating connecting body 5 has a two-stage stepped columnar structure.

[0050] Such as Figure 1~3 As shown, in the structure of the double grid control type cold cathode ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com