Resin consolidated abrasive diamond wire and production process thereof

A technology of consolidating abrasives and production technology, which is applied in the field of diamond wire, and can solve problems such as affecting the cutting effect, reducing the breaking force of the electroplated diamond wire, and corrosion of the core steel wire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

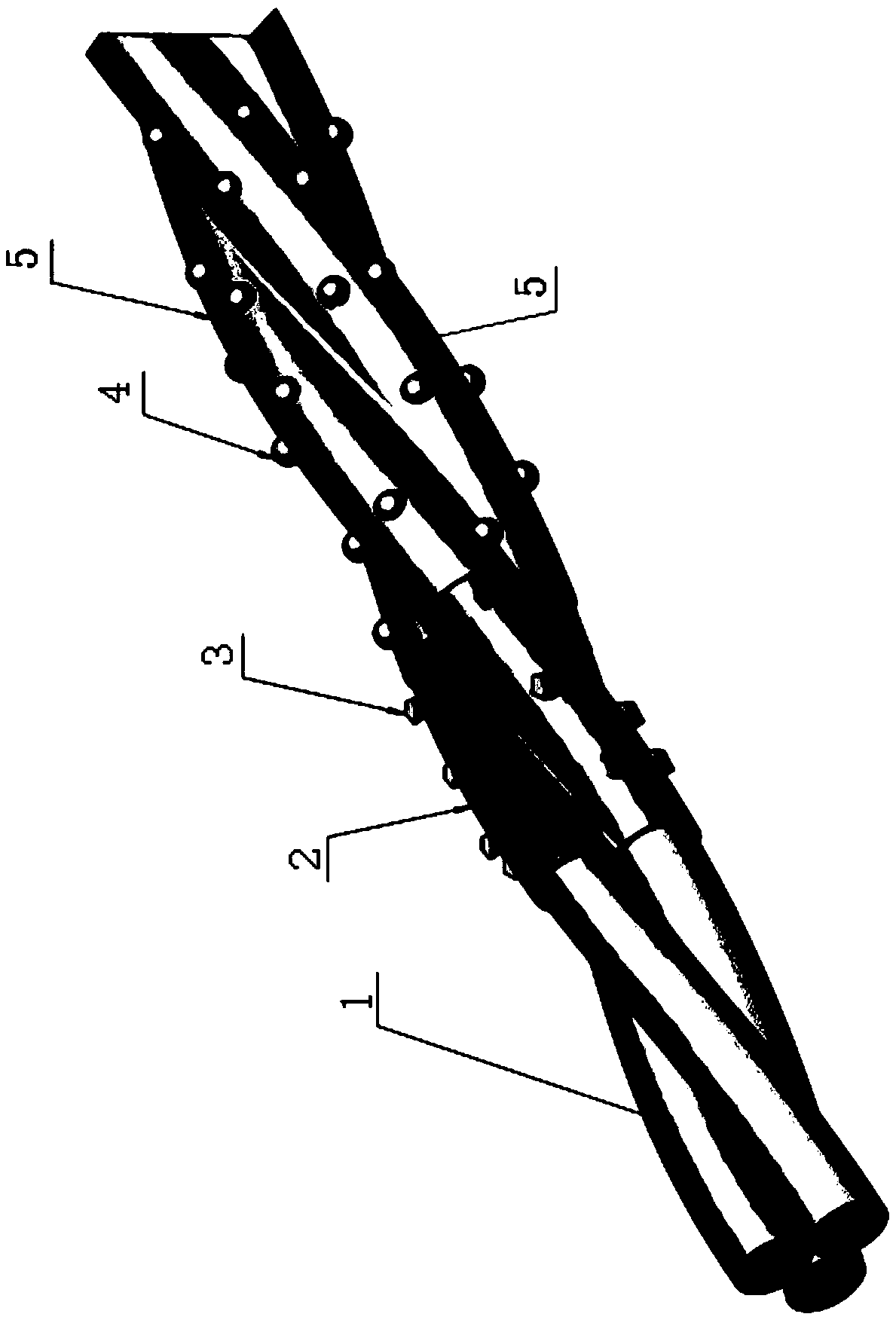

[0028] (1) Core rope production: The core rope is made of 3 strands of φ0.08mm high-strength steel wire;

[0029] (2) Surface pretreatment: The above-mentioned core ropes are released through the pay-off wheel, and then go through the alkaline degreasing agent solution at 60±5°C, washing water, 10% sulfuric acid solution at 40±5°C and washing water respectively. Dry at 110±5°C to obtain a core rope with a clean surface;

[0030] (3) Core rope plating bottom coating: brass bottom coating is plated on the outer surface of the core rope;

[0031] (4) Resin slurry coating: uniformly coat the phenolic resin slurry with diamond powder with a particle size of 20 μm on the surface of the core rope to obtain a resin diamond wire, wherein the method of coating the core rope is to install the core rope on On the wire feeding shaft, the core rope passes through the mold and runs continuously at a speed of 0.5m / s-1m / s;

[0032] (5) Initial curing of the resin diamond wire: the resin diam...

Embodiment approach 2

[0035] The difference from Example 1 is that the core rope in the step (1) of making the core rope is a core rope made by twisting three φ0.09mm steel wires. Step (2) surface pretreatment adopts 100-200g / l mixed acid to carry out pickling, described mixed acid comprises sulfuric acid 30%, oxalic acid 10%, hydrochloric acid 15%, phosphoric acid 10%, thiourea 0.5%, benzotriazepine azole 0.5%, the rest is water. Step (4) The diameter of the diamond micropowder particles in the resin slurry coating is 30 μm, and the steps (5) and (6) are the same as in Embodiment 1.

Embodiment approach 3

[0037] The difference from Embodiment 1 is that the surface pretreatment in step (2) uses 100-200g / l mixed acid for pickling, and the mixed acid includes 30% sulfuric acid, 10% oxalic acid, 15% hydrochloric acid, and 10% phosphoric acid. %, 0.5% thiourea, 0.5% benzotriazole, and the rest is water. Step (4) In the resin slurry coating, the line speed is 1.0m / s-1.5m / s, and the resin used is a mixture of phenolic resin and epoxy resin in a mass ratio of 4:1. Step (5) In the initial curing of the resin diamond rope, the temperature is 600±50° C. and the initial curing is rapid for 20 seconds. Step (6) During the curing of the resin diamond rope, the temperature is raised to 200° C. within 8 hours, isothermally raised every hour, kept for another 5 hours, and then naturally lowered to room temperature.

[0038] Of course, the resin slurry of the present invention can also be made of polyimide resin or its mixture with phenolic resin and epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com