Fruit washing salt and preparation method

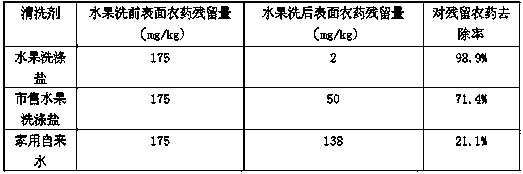

A technology for washing salts and fruits, applied in detergent compositions, chemical instruments and methods, non-surface-active detergent compositions, etc., can solve the problems of causing cancer, residues, environmental pollution, etc., and achieve no side effects and strong decontamination effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 A fruit washing salt prepared from the following main raw materials in parts by weight (each part is 1200g): 83 parts of table salt, 5 parts of Malan, 7 parts of tea saponin, 4 parts of paeonol, 3 parts of honeycomb, 5 parts of rose, 3 parts of rose flower, 8 parts of mung bean, 6 parts of coix seed, 3 parts of sodium bicarbonate, 4 parts of citric acid, and 0.5 part of natural stabilizer.

[0036] The natural stabilizer used in this example is gum arabic, purchased from Cangzhou Kangxin Beeswax Rubber Industry Co., Ltd.

[0037] The preparation method of above-mentioned fruit washing salt is characterized in that, the steps are as follows:

[0038] (1) Take roses, dry them, crush them into coarse powder, pass through a 80-mesh sieve, place them in a distiller, add water 9.6 times the weight of roses, and distill for 1.4 hours at a temperature of 82°C. After condensation, pass After centrifugation at 5200r / min for oil-water separation, volatile oil is obtaine...

Embodiment 2

[0043] Example 2 A fruit washing salt prepared from the following main raw materials in parts by weight (each part is 1200g): 93 parts of table salt, 8 parts of Malan, 10 parts of tea saponin, 9 parts of paeonol, 7 parts of honeycomb, 9 parts of roses, 7 parts of rose flowers, 12 parts of mung beans, 10 parts of coix seed, 5 parts of sodium bicarbonate, 7 parts of citric acid, and 0.8 parts of natural stabilizer.

[0044] The natural stabilizer used in this example is gum arabic, purchased from Cangzhou Kangxin Beeswax Rubber Industry Co., Ltd.

[0045] The preparation method of above-mentioned fruit washing salt is characterized in that, the steps are as follows:

[0046](1) Take roses, dry them, crush them into coarse powder, pass through a 80-mesh sieve, place them in a distiller, add water 13 times the weight of roses, and distill for 2 hours at a temperature of 96°C. After condensation, pass After centrifugation at 5200r / min for oil-water separation, volatile oil is obta...

Embodiment 3

[0050] Example 3 A fruit washing salt prepared from the following main raw materials in parts by weight (each part is 1200g): 85 parts of table salt, 6 parts of Malan, 8 parts of tea saponin, 6 parts of paeonol, 4 parts of honeycomb, 6 parts of rose, 4 parts of rose flower, 9 parts of mung bean, 7 parts of coix seed, 3.5 parts of sodium bicarbonate, 5 parts of citric acid, and 0.6 part of natural stabilizer.

[0051] The natural stabilizer used in this example is konjac polysaccharide, purchased from Xi'an Botete Biotechnology Co., Ltd.

[0052] The preparation method of above-mentioned fruit washing salt is characterized in that, the steps are as follows:

[0053] (1) Take roses, dry them, crush them into coarse powder, pass through a 80-mesh sieve, place them in a distiller, add water 10 times the weight of roses, and distill for 1.5 hours at a temperature of 86°C. After condensation, pass After centrifugation at 5200r / min for oil-water separation, volatile oil is obtained;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com