Graphene-laminated composite doping method

A composite doping and graphene technology, applied in the coating and other directions, can solve the problems of weak interaction between small molecule dopants and graphene, easy migration and volatilization, and increased square resistance of graphene, so as to achieve uniform doping effect. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

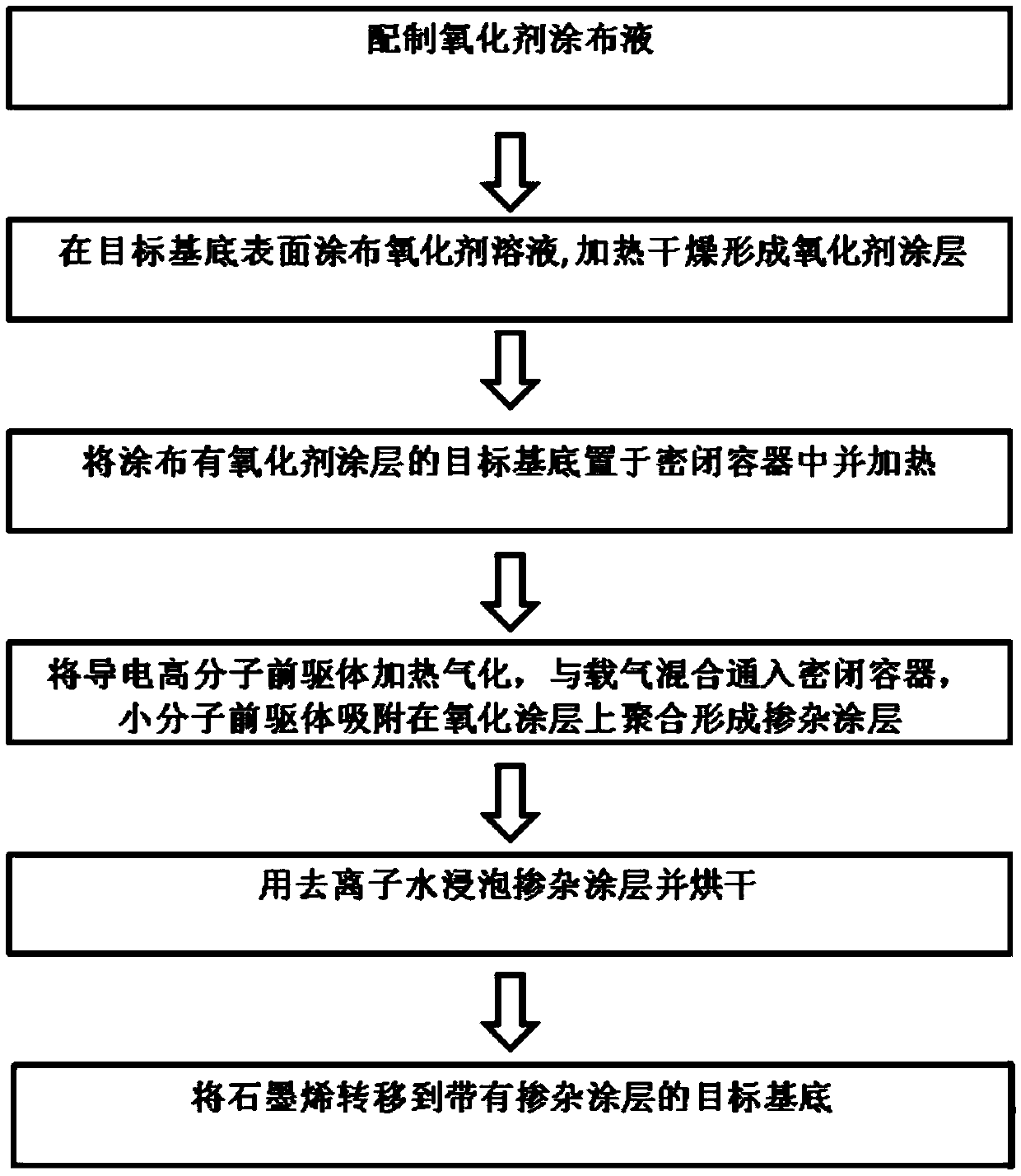

[0023] The steps of this embodiment are as follows:

[0024] Step 1, take by weighing 1.5g of ferric p-toluenesulfonate and dissolve in 350g of absolute ethanol, 600g of ethylene glycol and 450g of ethyl lactate to form a mixed solution, mix it into an oxidizing agent coating liquid after stirring;

[0025] Step 2: Apply the doped coating solution on the target substrate PET001 by roller coating method, and obtain an oxidant coating 002 with a film thickness of about 30 nm after drying;

[0026] Step 3, placing the PET substrate 001 coated with the oxidizing agent coating 002 in an airtight container and heating to 60°C;

[0027] Step 4: heating and vaporizing the 3,4-ethylenedioxythiophene small molecule monomer, and passing argon as a carrier gas into a closed container. The volume percentage of argon gas is 99%, the flow rate is 100 sccm, and the first doped coating 003 is formed on the surface of the target substrate PET001 after ventilation for 40 minutes;

[0028] Step...

Embodiment 2

[0032] The steps of this embodiment are as follows:

[0033] Step 1, taking 1g of ferric p-toluenesulfonate and dissolving it in a mixed solvent composed of 60g of isopropanol, 75g of n-butanol and 10g of ethylene glycol monobutyl ether, mixing evenly to form an oxidizing agent coating liquid;

[0034] Step 2, coating the doped coating solution on the optical grade PET substrate 001, and drying to obtain an oxidant coating 002 with a film thickness of about 10 nm;

[0035] Step 3, placing the PET substrate 001 coated with the oxidizing agent coating 002 in an airtight container, and heating to 90°C;

[0036] Step 4: Heat and vaporize the pyrrole small molecule monomer, and pass nitrogen gas as a carrier gas into an airtight container. The volume percentage of nitrogen gas is 95%, the flow rate is 50 sccm, and the first doped coating 003 is formed on the surface of the target substrate PET after ventilation for 30 minutes;

[0037] Step 5, soak the first doped coating 003 in ...

Embodiment 3

[0042] The steps of this embodiment are as follows:

[0043] Step 1, weigh 0.3g ferric p-toluenesulfonate and dissolve in a mixed solvent composed of 50g methanol, 60g isopropanol, 170g n-butanol, 8g ethylene glycol monomethyl ether and 5g ethylene glycol monobutyl ether, mix well Formulated as an oxidant coating solution;

[0044] Step 2: Coating the doped coating solution on the optical grade PET substrate 001, and drying to obtain an oxidant coating 002 with a film thickness of about 5 nm;

[0045] Step 3, placing the PET substrate 001 coated with the oxidizing agent coating 002 in an airtight container, and heating to 50°C;

[0046] Step 4: heating and vaporizing the thiophene small molecule monomer, and passing argon as a carrier gas into a closed container. The volume percentage of argon gas is 90%, the flow rate is 30 sccm, and the first doped coating 003 is formed on the surface of the target substrate PET001 after ventilation for 60 minutes;

[0047] Step 5, soak t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com