Anti-reflection self-cleaning photovoltaic coating glass and preparation method thereof

A technology of coated glass and self-cleaning film, which is applied in the field of antireflection and self-cleaning photovoltaic coated glass and its preparation, can solve the problems of reducing the antireflection effect of the film layer, low efficiency of coated glass, and inability to adapt to large-scale production, etc., to overcome the single Low transmittance of self-cleaning film, overcome poor anti-fouling performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

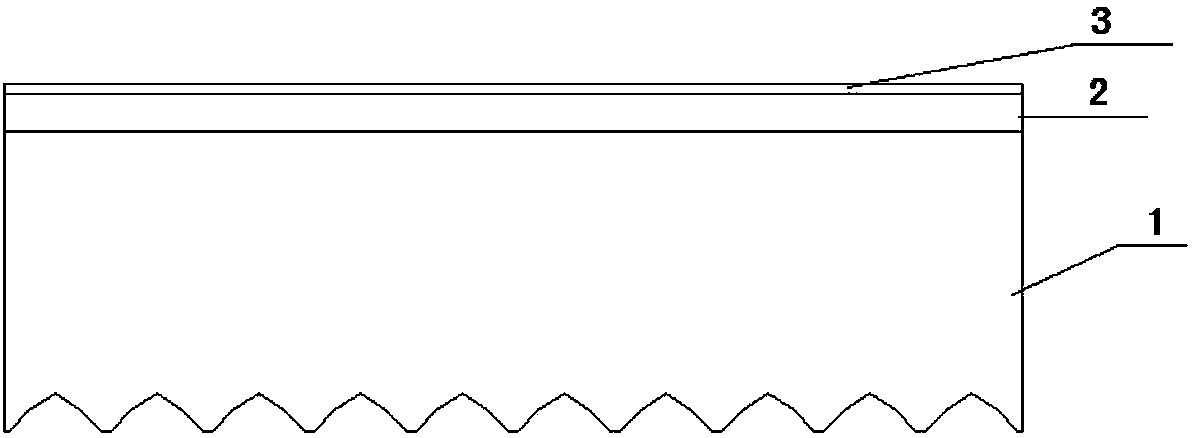

Image

Examples

preparation example Construction

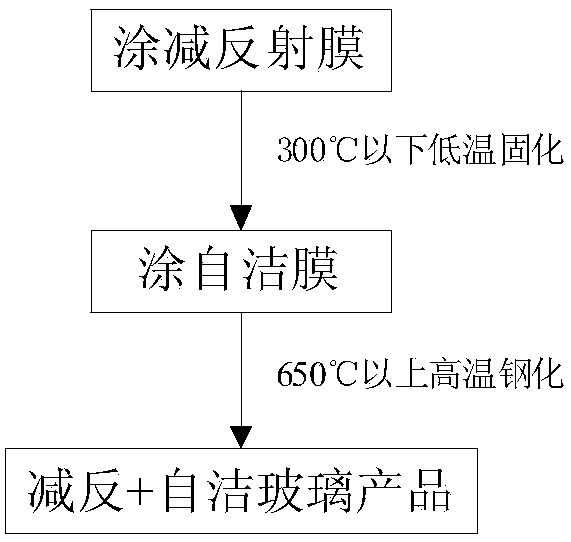

[0024] The present invention also relates to a preparation method of anti-reflective self-cleaning photovoltaic coated glass, comprising the following steps:

[0025] a) Coating an anti-reflection film: apply an anti-reflection film liquid on the basic side surface of the glass by a roll coating method, and then solidify at a low temperature to form an anti-reflection film layer; and

[0026] b) Coating a self-cleaning film: apply a self-cleaning film liquid on the anti-reflection film layer formed in step a) by roller coating or spraying, and then perform high-temperature tempering to form a tempered coated glass containing a self-cleaning film layer.

[0027] figure 2 A flow chart of the preparation method of the anti-reflection self-cleaning photovoltaic glass is shown.

[0028] In step a) of the present invention, the low-temperature curing condition is that the temperature is below 300° C. and heated for 2-5 minutes. The low temperature curing temperature is, for examp...

Embodiment 1

[0050] Clean the ultra-clear rolled glass (length 300mm, width 300mm, thickness 3.2mm, provided by Henan Ancai High-Tech Co., Ltd.) with a cleaning machine, and then use a roller coater to coat the glass wool with a silicon dioxide anti-reflection film solution. Wherein, the rotation speed of the coating roller in the roller coater is 7m / min, and the glass transmission speed is 6m / min. After coating the anti-reflection film, cure it in a thermostat at 150°C for 5 minutes to form a silicon dioxide anti-reflection film with a thickness of 100nm, and then use a roller coater to coat the titanium dioxide self-cleaning film solution, wherein the speed of the coating roller is 4m / min, the glass transmission speed is 9m / min, after the coating is completed, it is sent to a high-temperature tempering furnace for tempering, heated in the tempering furnace at 650°C for 150 seconds, and then the glass substrate is removed from the furnace, and then the high-pressure cold air is blown by a ...

Embodiment 2

[0052] Clean the ultra-clear rolled glass (length 300mm, width 300mm, thickness 3.2mm, provided by Henan Ancai High-Tech Co., Ltd.) with a cleaning machine, and then use a roller coater to coat the glass wool with a silicon dioxide anti-reflection film solution. Wherein the coating roller rotation speed in the roller coating machine is 7.5m / min, and the glass transmission speed is 6m / min. After coating the anti-reflection film, cure it in a thermostat at 150°C for 5 minutes to form a silicon dioxide anti-reflection film with a thickness of 120nm, and then use a roll coater to coat the titanium dioxide self-cleaning film solution, wherein the speed of the coating roller is 4m / min, the glass transmission speed is 9m / min, after the coating is completed, it is sent to a high-temperature tempering furnace for tempering, heated in the tempering furnace at 650°C for 150 seconds, and then the glass substrate is removed from the furnace, and then the high-pressure cold air is blown by a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com