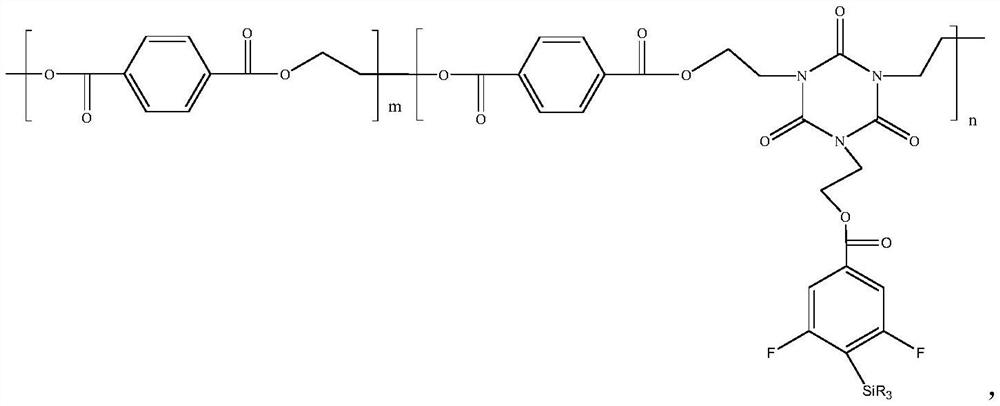

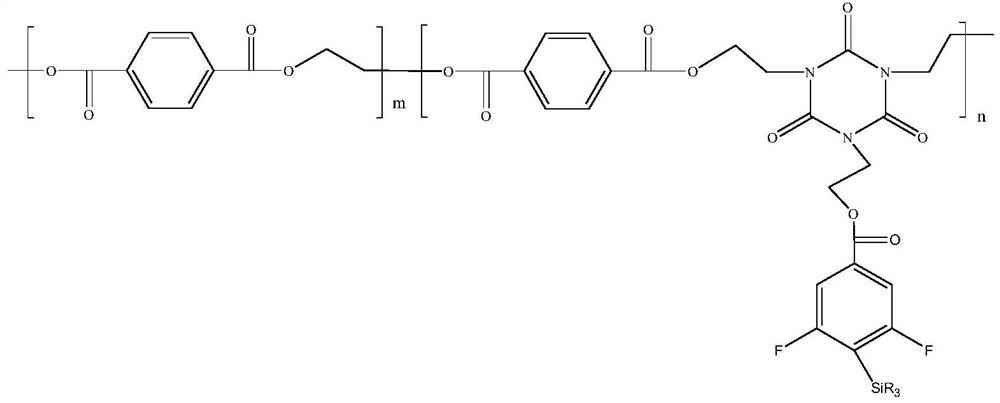

A kind of polyester and preparation method thereof

A technology of polyester and hydroxyethyl isocyanurate, which is applied in the field of new polyester and its preparation, can solve the problems of single function and flammability of polyester film, and achieve improved light transmittance, easy operation, and high water The effect of contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

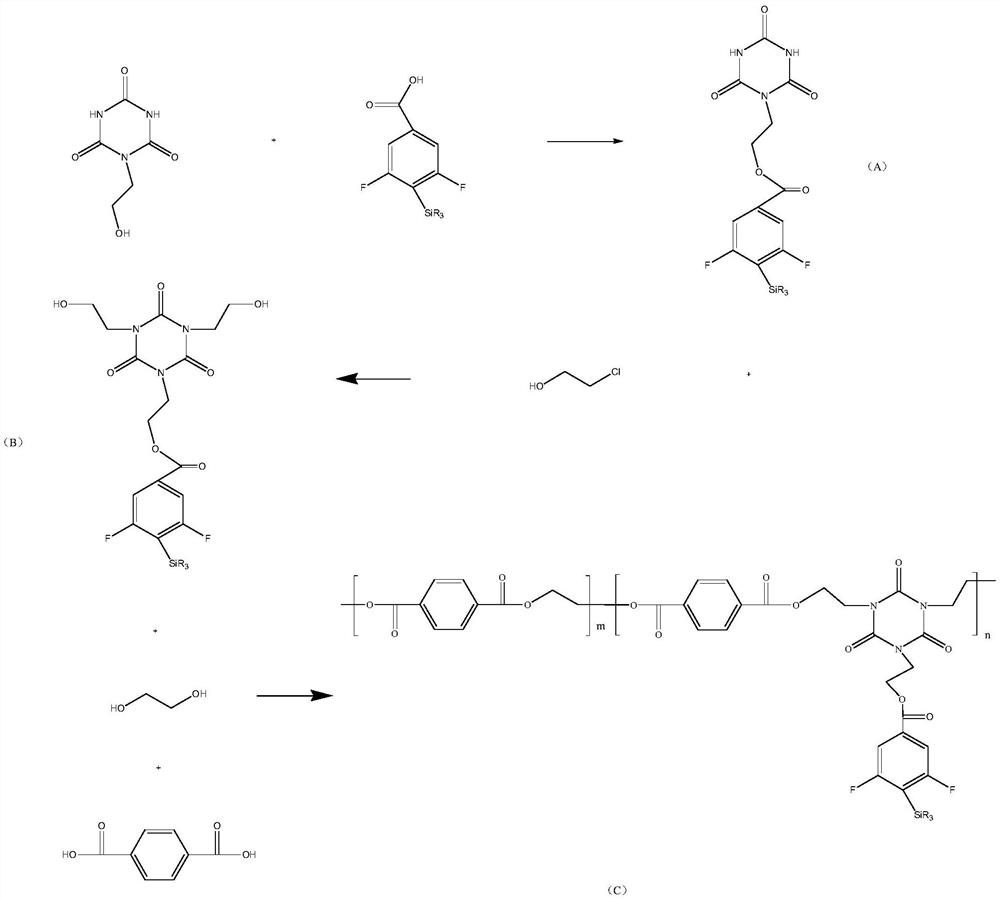

Method used

Image

Examples

Embodiment 1

[0036] Step 1) 1 part of hydroxyethylisocyanurate, 1.2 parts of 3-trihydrocarbylsilyl-2,4-difluorobenzoic acid (R is methyl), 0.01% part of 4-dimethylaminopyridine, 50 Put a portion of tetrahydrofuran in a three-necked flask, stir mechanically, heat and reflux for 20 hours, let stand, filter, distill the organic phase under reduced pressure, and dry in vacuum to obtain a colorless viscous liquid, that is, a fluorosilicone-modified isocyanurate derivative (IR: 3386cm -1 : -OH disappears; 1698cm -1 : Ester Ar-C=O exists; 1081cm -1 : C-F exists), denoted as A;

[0037] Step 2) Dissolve 1 part of A and 1 part of sodium hydroxide in 80 parts of water, heat the suspension to 90°C with vigorous stirring, and drop in 40 parts of water, 2 parts of sodium hydroxide and 4 parts of chloroethanol within 6 hours. The mixed cooling solution was left overnight, and then the solution was concentrated in vacuo, and the residual components were enriched. Add boiling N,N-dimethylformamide to ...

specific Embodiment 2-8

[0039] Specific embodiment 2-8, other are with specific embodiment 1, difference is following table:

[0040]

[0041] The polyester pellets obtained in specific example 1 were used as the base material of the application example, and it was made into a polyester film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com