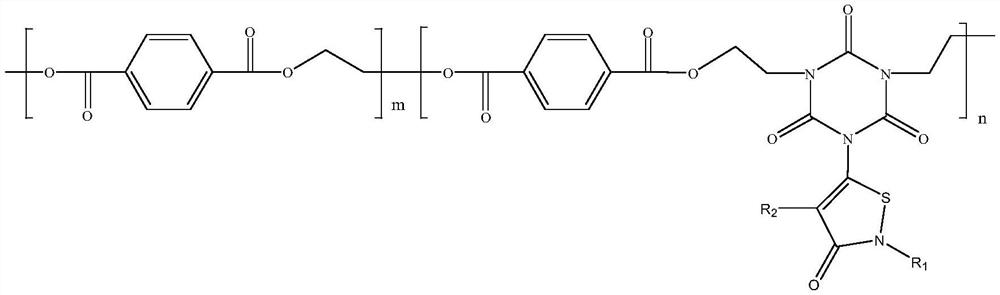

PET material and its preparation method, pellets and fiber products

A technology of pellets and isocyanurate, which is applied in the field of PET materials, can solve the problems of flammability of PET fibers, and achieve the effects of easy operation, single performance, and high-efficiency flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

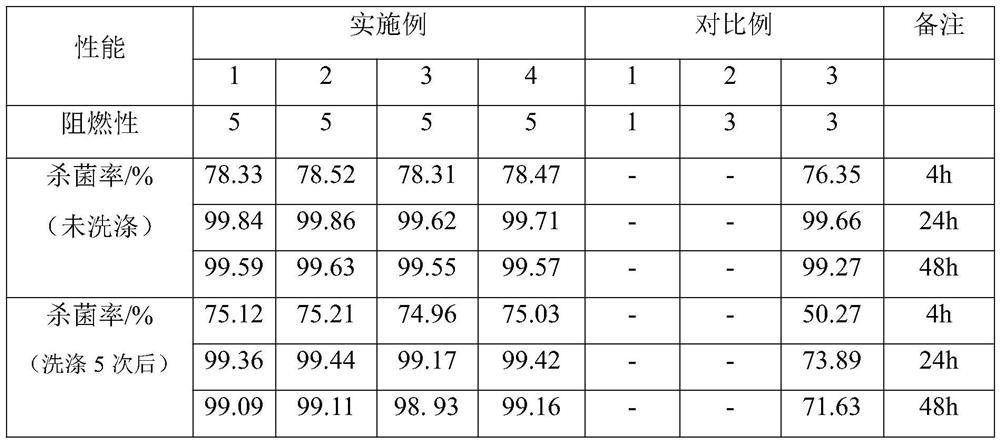

Examples

Embodiment 1

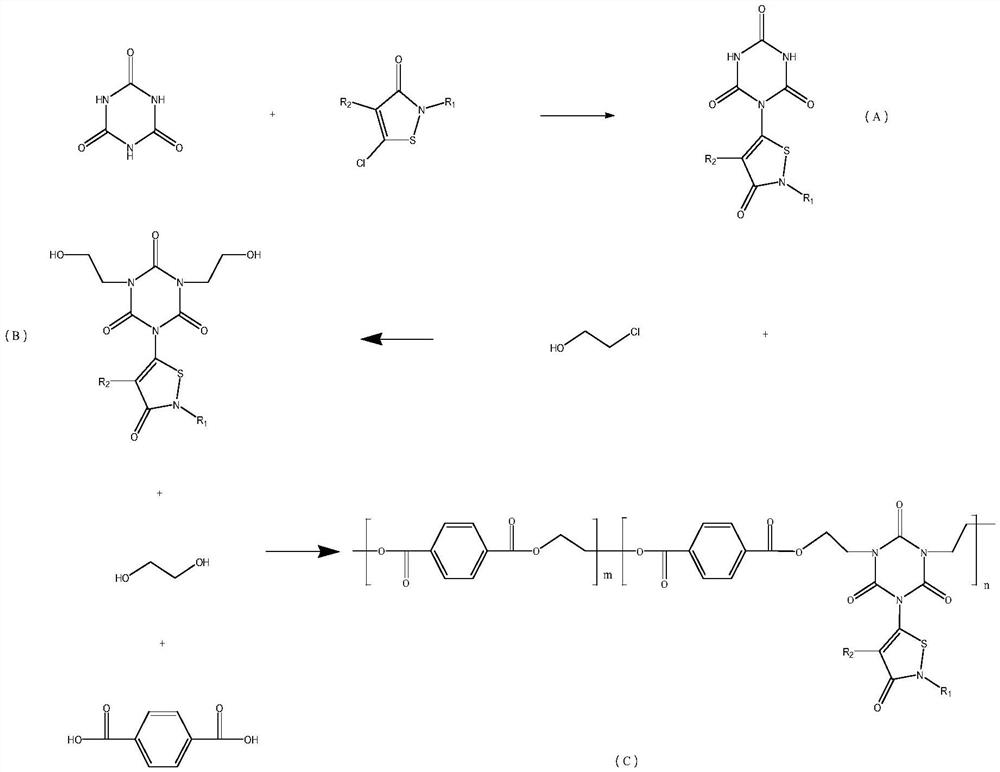

[0028] Embodiment 1: a kind of novel PET fiber preparation method that this embodiment provides, it comprises the following steps:

[0029] (1) 1 part of 5-chloro-2-methyl-4-isothiazolin-3-one derivative (R 1 :-CH 3 ; 2 :-H), 1 part of sodium hydroxide was added to 50 parts of water, heated to 80°C and vigorously stirred, added to 60 parts of dissolved 1 part of isocyanurate and 1 part of sodium hydroxide in 5 times within 12 hours For suspension in water, stir vigorously and heat to 90°C, keep warm until 3 hours after the addition is completed, cool, and after standing overnight, concentrate the solution in vacuo to enrich the residual components, add boiling N,N-dimethylformaldehyde The amide is dissolved, cooled after filtration, and rotary evaporated to obtain isocyanurate derivatives modified by isothiazolinone (IR: 1641cm -1 :-C=C-exists; 637cm -1 :-C-S-exists), denoted as A;

[0030] (2) Dissolve 1 part of A and 1 part of sodium hydroxide in 80 parts of water, stir...

Embodiment 2

[0033] Embodiment 2: a kind of novel PET fiber preparation method that this embodiment provides, it comprises the following steps:

[0034] (1) 1.2 parts of 5-chloro-2-methyl-4-isothiazolin-3-one derivatives (R 1 :-C 6 h 11 ; 2 :-F), 1 part of sodium hydroxide was added to 50 parts of water, heated to 90°C and vigorously stirred, added to 60 parts of 1 part of isocyanurate and 1 part of sodium hydroxide dissolved in 3 times within 8 hours For suspension of water, stir vigorously and heat to 95°C, keep warm until 3 hours after the addition is completed, cool, and stand overnight, then concentrate the solution in vacuo, the residual components are enriched, add boiling isopropanol to dissolve, filter Cooling, rotary steaming, obtained isocyanurate derivatives modified by isothiazolinone (IR: 1641cm -1 :-C=C-exists; 637cm -1 :-C-S-exists), denoted as A;

[0035] (2) Dissolve 1 part of A and 1 part of sodium hydroxide in 80 parts of water, stir the suspension vigorously and ...

Embodiment 3

[0038] Embodiment 3: a kind of novel PET fiber preparation method that this embodiment provides, it comprises the following steps:

[0039] (1) 1.1 parts of 5-chloro-2-methyl-4-isothiazolin-3-one derivatives (R 1 :-C 6 h 5 ; 2 :-Cl), 1 part of sodium hydroxide was added to 50 parts of water, heated to 70°C and vigorously stirred, added to 60 parts of dissolved 1 part of isocyanurate and 1 part of sodium hydroxide in 4 times within 10 hours For suspension in water, stir vigorously and heat to 93°C, keep warm until 3 hours after the addition is completed, cool, and after standing overnight, concentrate the solution in vacuo to enrich the residual components, add boiling dioxane to dissolve, filter After cooling, rotary steaming, obtain isothiazolinone modified isocyanurate derivatives (IR: 1641cm -1 :-C=C-exists; 637cm -1 :-C-S-exists), denoted as A;

[0040] (2) Dissolve 1 part of A and 1 part of sodium hydroxide in 80 parts of water, stir the suspension vigorously and he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com