Selective solar energy absorbing coating and method for making same

An absorbing coating and selective technology, applied in the field of solar heat collection, can solve the problems of high emissivity, low deposition rate and long production cycle in high temperature area, and achieve low emissivity, good thermal stability and improved absorption rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

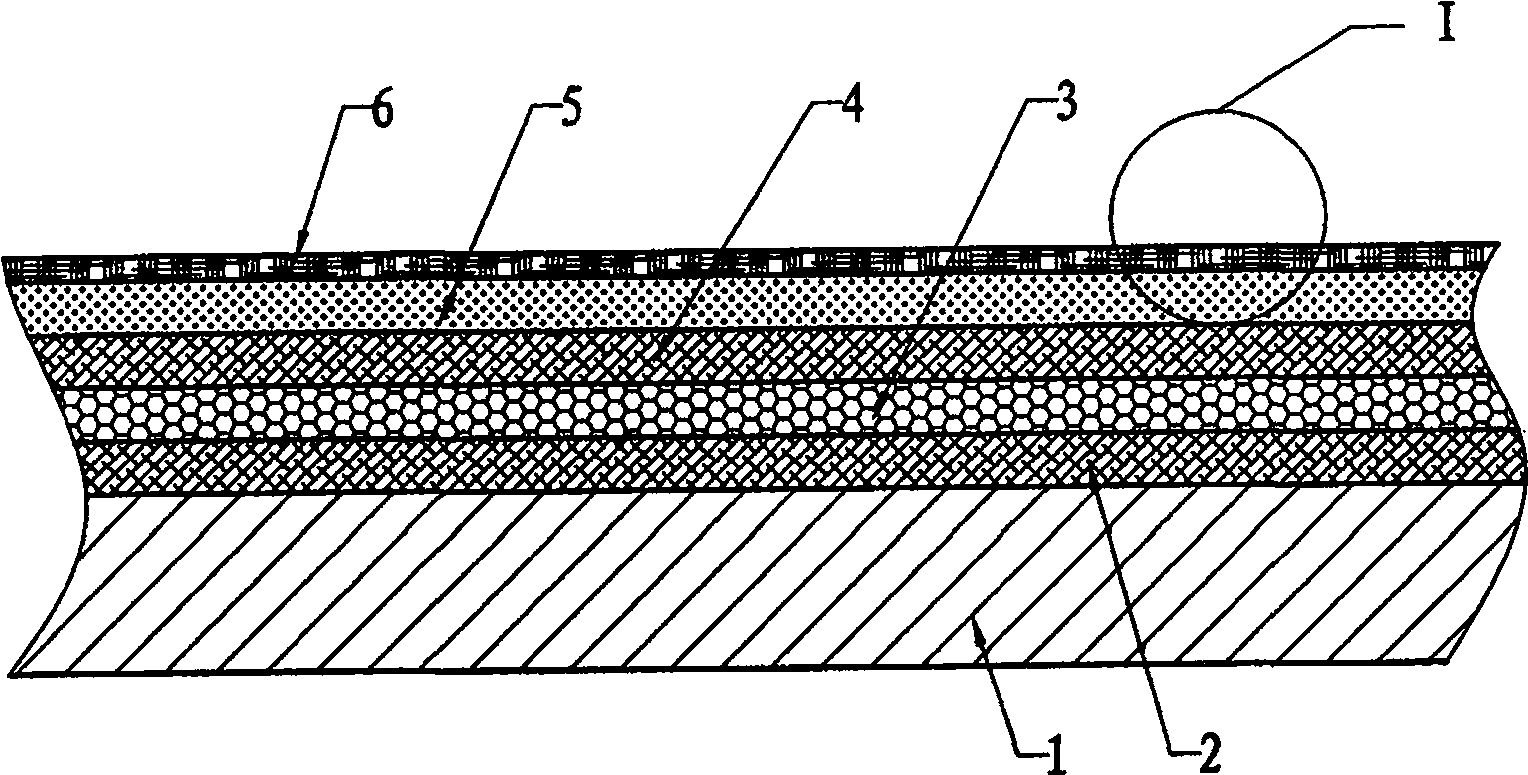

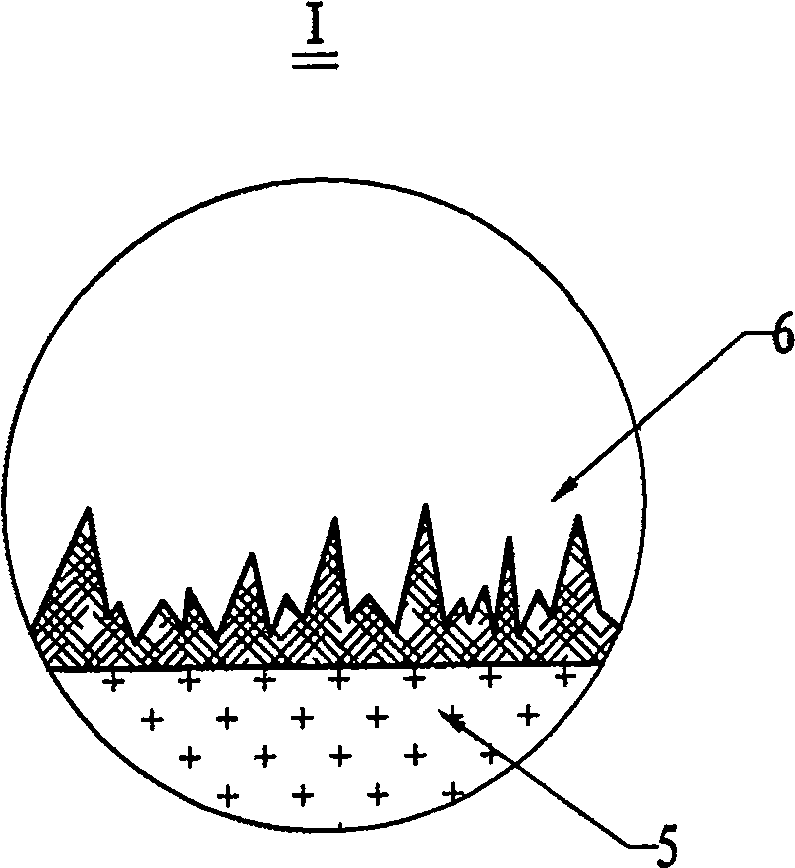

[0037] like figure 1 As shown, the solar selective absorbing coating includes a substrate layer 2, a thermal diffusion barrier film layer 3, a reflective layer 4, an absorbing layer 5, and a slightly uneven surface layer 6 arranged in sequence on the outer surface of the inner tube 1. The preparation of the solar energy selective absorption coating adopts a two-target sputtering device, one target uses Ni, and the other uses MgO; the two targets are separated by a baffle to prevent interference between film layers during coating. First turn on the mechanical pump to pre-pump the coating chamber, then turn on the diffusion pump to evacuate the coating chamber to an order of magnitude of 10 -3 Pa, through argon to order of magnitude 10 -1 Pa. Then the Ni target is energized and sputtered to prepare the substrate layer 2 . After the Ni film thickness of the deposited substrate layer reaches 50-100nm, the Ni target is powered off. The reason why substrate layer 2 adopts Ni thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com