Interlayer light-emitting glass device and automobile skylight

A luminous glass and interlayer technology, applied in the field of lighting, can solve the problems of reducing durability, reducing glass permeability and durability, etc., and achieve the effects of high transparency, various quality improvements, and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

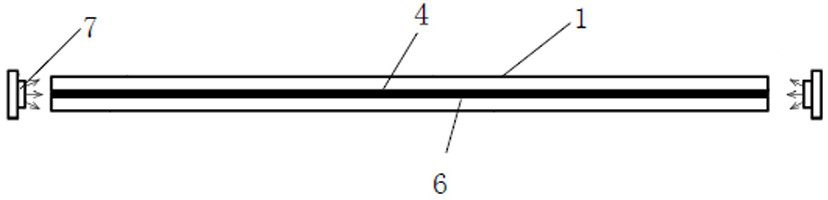

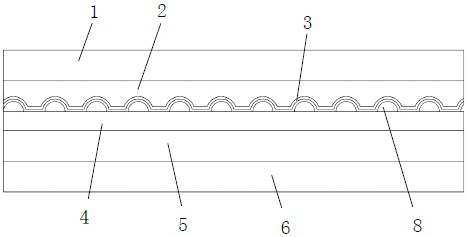

[0038] see Figures 1 to 4 The core of the present invention is to provide a laminated light-emitting glass device, including a light source component and a light-emitting glass component. The light source component is used to provide light and is arranged on the light-incident side of the light-emitting glass component. , to make it glow.

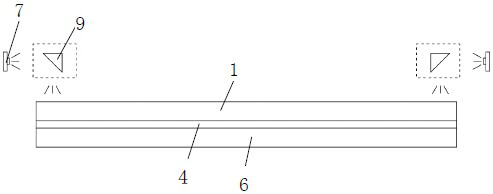

[0039] The light source assembly includes an LED lamp 7 and an introduction device. The LED lamp 7 provides light and is introduced into the light-emitting glass assembly through the introduction device. The introduction means may be one or more of gratings, prisms 9 and microstructures. And the light introduction method can be side incident light, forward incident light, or a combination of the two. The light source component can be arranged on the side or the front of the light-emitting glass component, that is to say, the light-incident side of the light-emitting glass component can be on the side of the light-emitting glass component....

Embodiment 2

[0054] Another core of the present invention is to provide an automobile sunroof, which adopts the laminated light-emitting glass device of Embodiment 1. The laminated light-emitting glass device is arranged in the hollow of the top of the automobile. Buckles, such as U-shaped buckles, are mounted directly on the side walls of the luminous glass assembly. The laminated light-emitting glass device can make the entire light-emitting glass component emit light uniformly when light is introduced, and the light-emitting glass component is transparent when no light is introduced, which can be used as ordinary glass and can also be used for lighting. Used as a car sunroof, it does not affect the sight of the sunroof when the light is off, and it is almost completely transparent. When the light is on, the entire sunroof is illuminated to achieve the effect of interior lighting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com