Preparation method of laminated thermoelectric battery

A technology of thermoelectric battery and thermoelectric power generation module, which is applied in the direction of manufacturing/processing of thermoelectric devices, can solve problems such as not being able to exert the best performance, and achieve the effects of avoiding poor welding, easy implementation, and improved power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

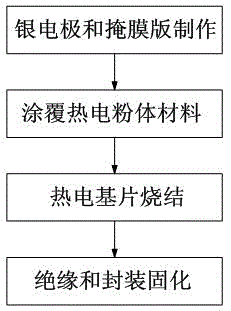

[0043] The invention provides a novel method for preparing a thermoelectric battery (stacked thermoelectric battery). Such as figure 1 As shown, specifically, the present invention mainly includes several major steps of making silver electrodes and masks, coating thermoelectric powder materials, sintering thermoelectric substrates, insulating and encapsulating and curing.

[0044] 1. Fabrication of silver electrodes and masks

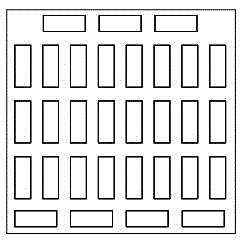

[0045] Firstly, the screen printing screen is designed according to the assembly form of the thermoelectric power generation module, and then the first silver electrode is obtained by screen printing and sintering on one surface of a ceramic substrate. A second silver electrode is obtained by screen printing and sintering process on one surface. The sintering temperature is 850-950° C., and the sintering time is 30-60 minutes, and the ceramic substrate is preferably an alumina ceramic substrate in this embodiment. The first silver electrode that pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com