80ksi anti-h for shale gas 2 s-corrosion casing steel and manufacturing method thereof

An 80ksi, manufacturing method technology, applied in the field of steel manufacturing, can solve the problems of uncorroded casing steel manufacturing methods, etc., and achieve the effects of improving H2S stress corrosion resistance, reducing production costs, and good internal and external surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

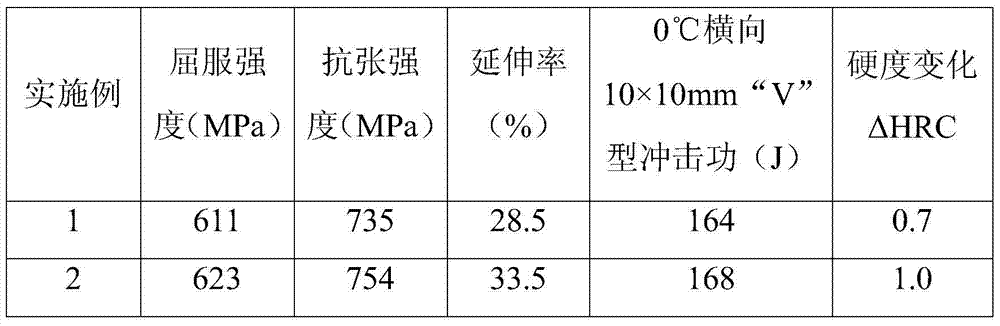

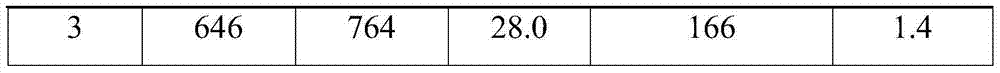

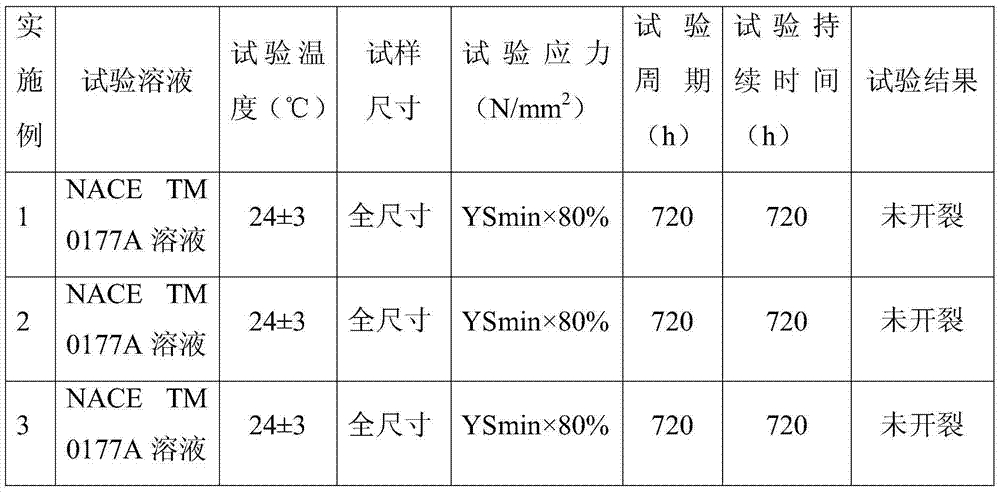

Examples

Embodiment 1

[0038] steelmaking

[0039] Electric furnace smelting: pig iron and common carbon steel scrap are used as raw materials, smelted in an electric arc furnace, and the end point C0.10%, P 0.005%, the initial molten steel at a temperature of 1628 ° C, the furnace is tapped, and the steel process is deoxidized Addition amount of agent: Add CaAlSi 2.0kg / t steel, Al block addition amount 1.5kg / t steel to ensure good deoxidation.

[0040]LF refining and VD vacuum treatment: LF refining is performed on the molten steel initially smelted in an electric furnace, and after refining, it is fed into Ca wire 0.08kg / t steel for calcium treatment; after calcium treatment, VD vacuum degassing treatment is carried out, and the degassing is carried out at a vacuum degree ≤ 67Pa Gas treatment for 15 minutes; break the air when the VD vacuum treatment time reaches the requirement, and perform static blowing treatment with the VD vacuum chamber covered with a cover. The static blowing time is 20 min...

Embodiment 2

[0051] steel making

[0052] Electric furnace smelting: pig iron and common carbon steel scrap are used as raw materials, smelted in an electric arc furnace, and the end point C0.11%, P 0.008%, the initial molten steel at a temperature of 1630 ° C, the furnace is tapped, and the steel process is deoxidized Addition amount of agent: Add CaAlSi 3.0kg / t steel, Al block addition amount 1.0kg / t steel to ensure good deoxidation.

[0053] LF Refining and VD Vacuum Treatment: LF refining is performed on the molten steel initially smelted in an electric furnace. After refining, 0.10kg / t steel is fed into Ca wire for calcium treatment; after calcium treatment, VD vacuum degassing treatment is carried out, and the degassing is carried out at a vacuum degree ≤ 67Pa. Gas treatment for 15 minutes; break the air when the VD vacuum treatment time reaches the requirement, and perform static blowing treatment with the VD vacuum chamber cover covered. The static blowing time is 25 minutes, and t...

Embodiment 3

[0064] steel making

[0065] Electric furnace smelting: pig iron and common carbon steel scrap are used as raw materials, smelted in an electric arc furnace, and the end point C0.08%, P 0.004%, the initial molten steel at a temperature of 1640 ° C, the furnace is tapped, and the steel process is deoxidized Addition amount of agent: add CaAlSi 3.0kg / t steel, and Al block addition amount 1.5kg / t steel to ensure good deoxidation.

[0066] LF refining and VD vacuum treatment: LF refining is carried out on the molten steel initially smelted in an electric furnace. After refining, 0.09kg / t of Ca wire is fed for calcium treatment; after calcium treatment, VD vacuum degassing treatment is carried out, and degassing at a vacuum degree ≤ 67Pa Treat for 15 minutes; break the air when the VD vacuum treatment time reaches the requirement, and perform static blowing treatment with the VD vacuum chamber covered with a cover. The static blowing time is 23 minutes, and the bottom blowing Ar ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com