Low temperature resistant anti-crack powder coating used for water pumps and preparation method thereof

A technology of powder coatings and low temperature resistance, applied in powder coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of poor bonding ability between coatings and metal substrates, poor low temperature resistance, poor impact resistance, etc., to achieve Excellent cavitation resistance, strong binding force and high compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

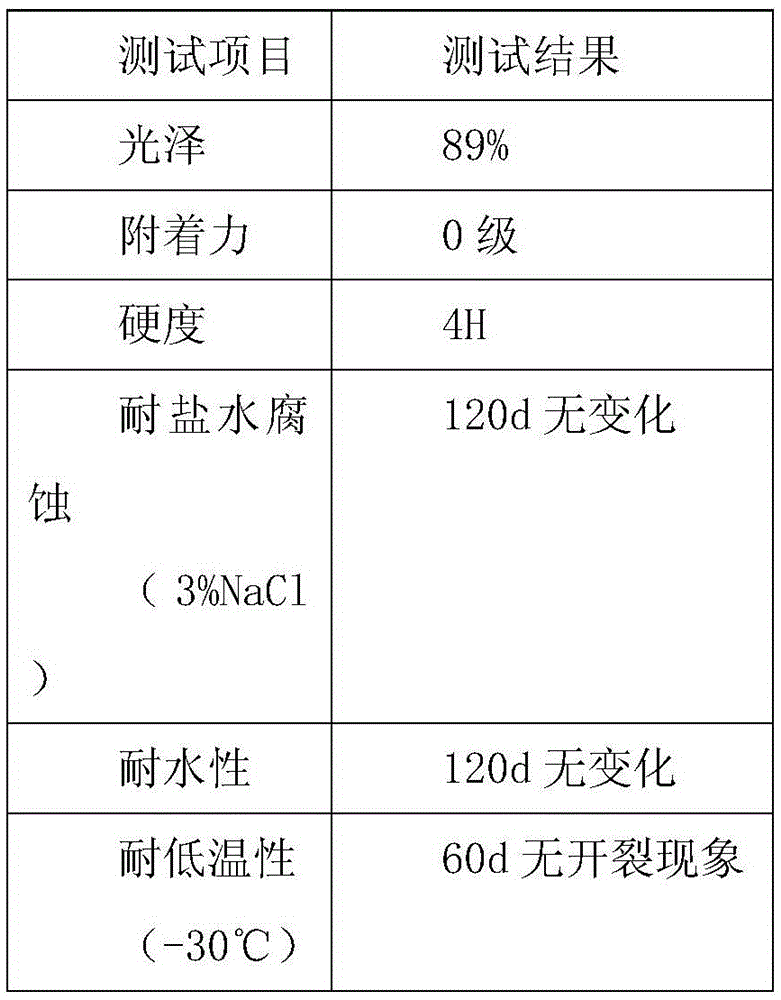

Examples

Embodiment Construction

[0015] A kind of low-temperature resistant anti-cracking water pump powder coating, it is made by the following raw materials of weight part:

[0016] Bisphenol A epoxy resin 40, cellulose acetate butyrate 3, acetyl tributyl citrate 1, bentonite 20, talc powder 5, styrene-acrylic emulsion 3, zirconium sol 1.5, aluminum sol 4, water-based polyurethane emulsion 3, phenol Class curing agent 3, film-forming aid 3;

[0017] The solid content of the zirconium sol is 20%, the solid content of the aluminum sol is 20%, the solid content of the aqueous polyurethane emulsion is 40%, and the solid content of the styrene-acrylic emulsion is 50%;

[0018] The film-forming aid is made of the following raw materials in parts by weight: rosin 2, epoxidized soybean oil 5, acrylic acid 3, glyceryl monostearate 0.5, silane coupling agent KH-5600.3; the preparation method of the film-forming aid First, melt and blend rosin, epoxidized soybean oil and glyceryl monostearate at 160°C, then adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com