A kind of method that takes C9 fraction as raw material to prepare petroleum resin

A petroleum resin and raw material technology, applied in the field of petroleum resin preparation, can solve the problems of petroleum resin performance degradation, difficulty in catalyst removal, and influence on post-treatment process, etc., achieve stable performance, solve emulsification phenomenon, and easy control of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

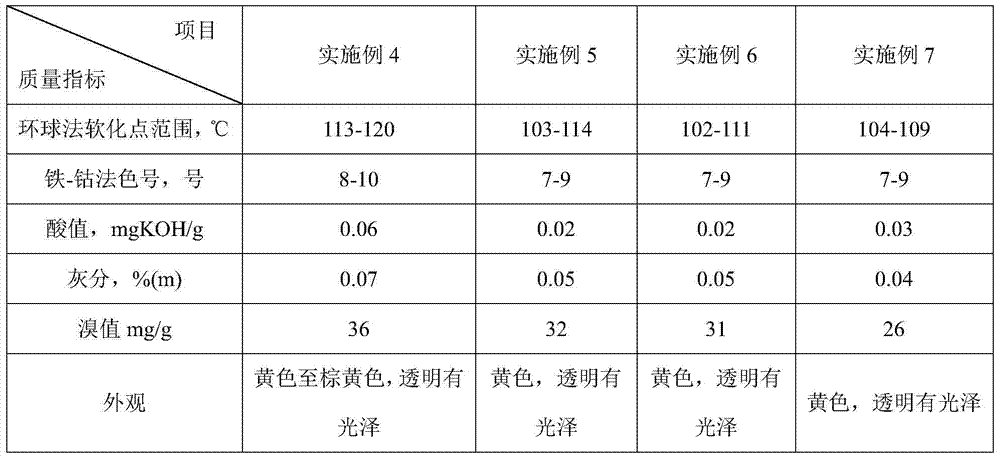

Examples

Embodiment 1

[0021] Dissolve 1 g of the template agent cetyltrimethylammonium bromide (CTAB) in 200 ml of deionized water, and stir in a water bath at 40°C. Then add 5ml of ammonia water, dropwise add 40g of tetraethyl orthosilicate, and add 4g of aluminum isopropoxide at the same time, then stir in a 40°C water bath for 4h. Then the liquid was transferred to a polytetrafluoroethylene-lined stainless steel reactor, crystallized at 80°C for 72 hours, filtered, washed with distilled water until neutral, and dried. Finally, it was put into a muffle furnace and calcined at 450°C for 6 hours to remove the template agent and obtain Al-MCM-41.

[0022] 5 g of the Al-modified MCM-41 carrier obtained above was added to 30 ml of 20% phosphotungstic acid ethanol solution, stirred at room temperature for 12 hours, and separated by filtration. Dry at 80°C for 8 hours, and bake at 450°C for 3 hours. An Al-MCM-41 molecular sieve-loaded phosphotungstic acid catalyst with a silicon-aluminum ratio of 10 a...

Embodiment 2

[0024] Dissolve 1 g of the template agent cetyltrimethylammonium bromide (CTAB) in 200 ml of deionized water, and stir in a water bath at 40°C. Then 5ml of ammonia water was added, 40g of ethyl orthosilicate was added dropwise, and 0.8g of aluminum isopropoxide was added at the same time, and then stirred in a water bath at 40°C for 4h. Then the liquid was transferred to a polytetrafluoroethylene-lined stainless steel reactor, crystallized at 80°C for 72 hours, filtered, washed with distilled water until neutral, and dried. Finally, put it into a muffle furnace and bake it at 500°C for 6 hours to remove the template agent to obtain Al-MCM-41.

[0025] 5 g of the Al-modified MCM-41 carrier obtained above was added to 30 ml of phosphotungstic acid ethanol solution with a mass fraction of 35%, stirred at room temperature for 18 hours, and separated by filtration. Dry at 100°C for 10 hours and bake at 500°C for 3 hours. An Al-MCM-41 molecular sieve-loaded phosphotungstic acid ca...

Embodiment 3

[0027] Dissolve 1 g of the template agent cetyltrimethylammonium bromide (CTAB) in 200 ml of deionized water, and stir in a water bath at 40°C. Then, 5ml of ammonia water was added, 40g of tetraethyl orthosilicate was added dropwise, and 0.4g of aluminum isopropoxide was added at the same time, and then stirred in a water bath at 40°C for 4h. Then the liquid was transferred to a polytetrafluoroethylene-lined stainless steel reactor, crystallized at 80°C for 72 hours, filtered, washed with distilled water until neutral, and dried. Finally, put it into a muffle furnace and bake it at 550°C for 6 hours to remove the template agent, and obtain Al-MCM-41.

[0028] 5 g of the Al-modified MCM-41 carrier obtained above was added to 30 ml of 50% phosphotungstic acid ethanol solution, stirred at room temperature for 24 hours, and separated by filtration. Dry at 110°C for 12 hours and bake at 550°C for 3 hours. An Al-MCM-41 molecular sieve-loaded phosphotungstic acid catalyst with a si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com