Perlite fireproof thermal baffle and preparation method thereof

A technology of perlite and heat insulation board, which is applied in the field of fireproof and thermal insulation materials, can solve the problems of fire door core boards that cannot be embossed, low production efficiency, and glass fiber yarn cannot be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

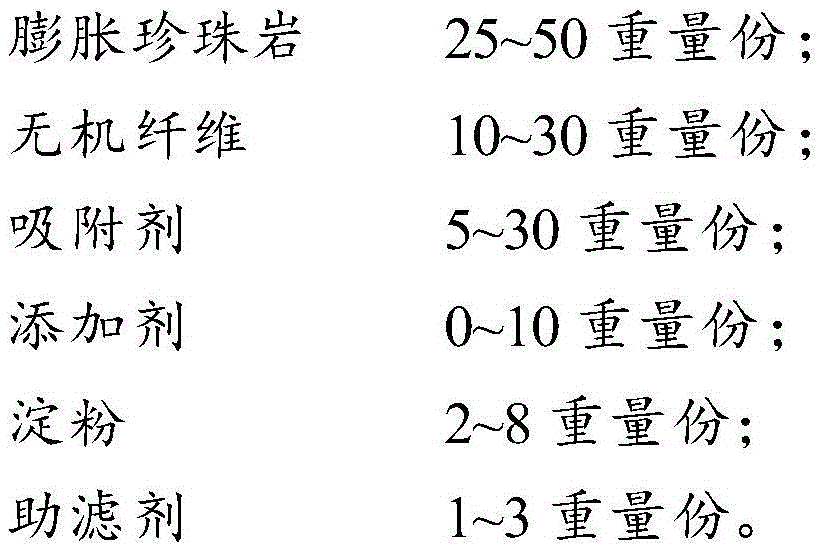

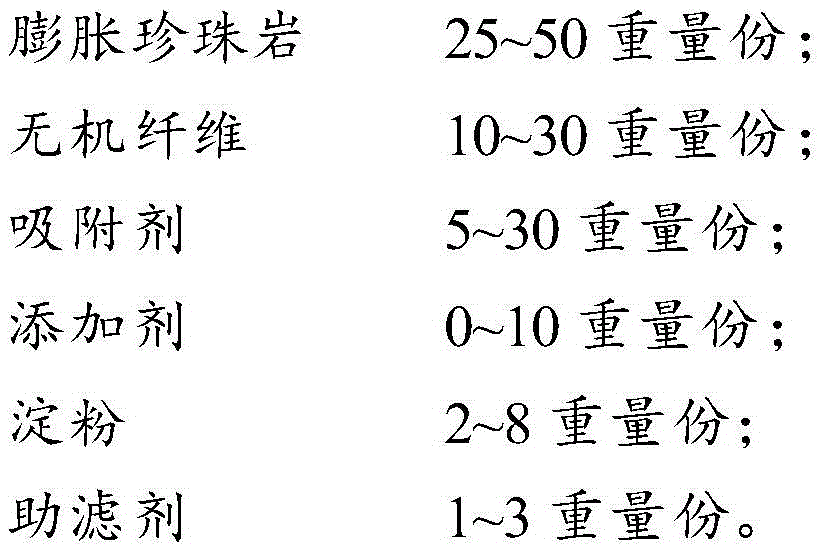

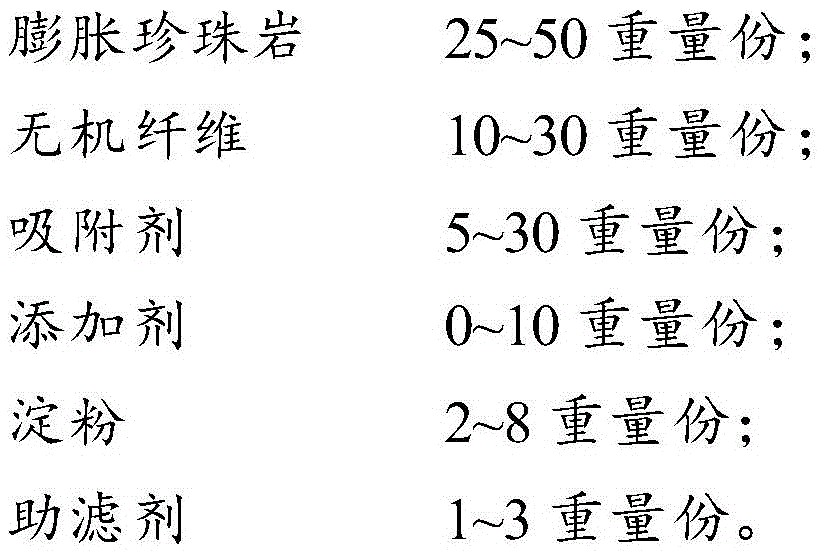

[0034] The present invention also provides a method for preparing the above-mentioned perlite fire-proof heat insulation board, comprising: A) adding 25-50 parts by weight of expanded perlite, 10-30 parts by weight of inorganic fibers, and 5-30 parts by weight of adsorbent , 0 to 10 parts by weight of additives, 2 to 8 parts by weight of starch, and 1 to 3 parts by weight of filter aid are mixed with water to obtain a slurry; B) filtering the slurry, pressing and molding, and drying Get perlite fire rated insulation board.

[0035] Wherein, the expanded perlite, inorganic fibers, adsorbents, additives, starch and filter aids are all the same as above, and will not be repeated here.

[0036] The present invention preferably first mixes 25-50 parts by weight of expanded perlite, 5-30 parts by weight of adsorbent, and 0-10 parts by weight of additives with water, more preferably first mixes with part of water, and then adds 10-30 parts by weight of parts of inorganic fiber, stir...

Embodiment 1

[0044] 1.1 Add 800Kg of open-pore perlite, 150Kg of xonotlite, and 100Kg of antimony trioxide, a flame retardant, into the mixing tank filled with water in advance for stirring.

[0045] 1.2 Add 400Kg of glass fiber to the mixing tank, continue stirring, and make the perlite evenly dispersed in the water without floating through the synergistic effect of glass fiber and xonotlite.

[0046] 1.3 Add 50Kg of starch, 20Kg of polyaluminum chloride, and 25Kg of polyacrylamide, transfer the slurry to the slurry storage tank and inject water. The total amount of water added is 30 tons.

[0047] 1.4 Pump the slurry to the high tank to ensure that the slurry always maintains the same height during the molding process.

[0048] 1.5 Evenly disperse the slurry on the conveyor belt and filter it to form; the filtered slurry is pressed by a pressure roller to a thickness of 50mm and a bulk density of 260Kg / m 3 The perlite board is sent to the drying room for drying to obtain the perlite fir...

Embodiment 2

[0051] 2.1 Add 700Kg of open-pore perlite, 200Kg of sepiolite, and 100Kg of silicone water-repellent agent into the mixing tank filled with water in advance for stirring.

[0052] 2.2 Add 300Kg of slag wool to the mixing tank and continue to stir. Through the synergistic effect of slag wool and sepiolite, the perlite is evenly dispersed in the water without floating.

[0053] 2.3 Add 70Kg of starch, 20Kg of polyaluminum chloride and 25Kg of polyacrylamide, transfer the slurry to the slurry storage tank and inject water, the total amount of water added is 25 tons.

[0054] 2.4 Pump the slurry to the high tank to ensure that the slurry always maintains the same height during the molding process.

[0055] 2.5 Evenly disperse the slurry on the continuous conveyor belt and form it by filtration; the filtered slurry is pressed by a pressure roller to a thickness of 20mm and a bulk density of 300Kg / m 3 The perlite board is sent to the drying room for drying to obtain the perlite fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com