Advanced treatment method of nitrate-containing water

An advanced treatment and nitrate technology, applied in the field of water treatment, can solve the problems of large investment in the combined process of activated sludge and membrane bioreactor, affecting the sedimentation effect of the secondary sedimentation tank, and complicated operation, and achieves good sedimentation performance and investment. Less and more efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

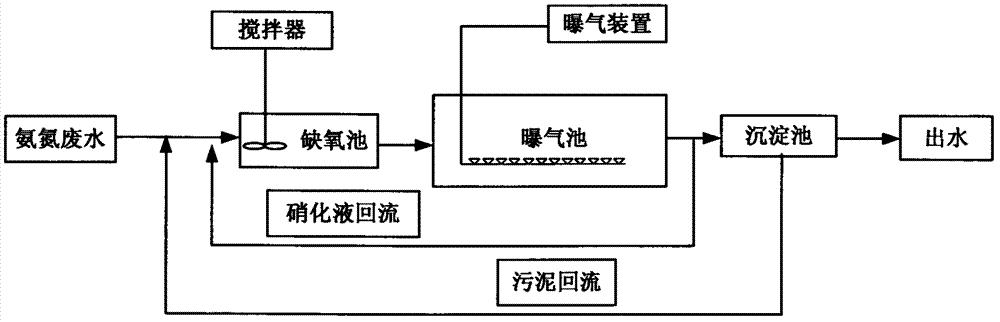

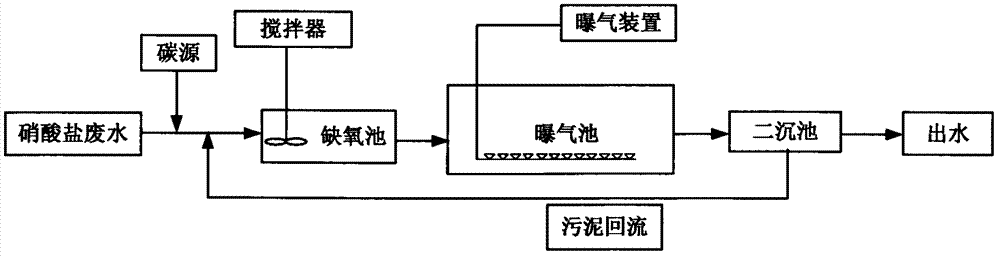

[0026] The schematic diagram of the technological process of the advanced treatment of nitrate-containing wastewater in this embodiment is as follows figure 2 shown.

[0027] The concentration of nitrate in groundwater in a certain area is 20mg·L -1 About, the COD value is 10mg·L -1 ~50mg·L -1 , pH 6.0-9.0, seriously exceeding the standard, and the present invention is applied to treat it. The treated water volume is 10000m 3 d -1 , the main structures are: (1) anoxic pool (denitrification pool), pool size: 10×10×5.5m, effective volume: 500m 3 , equipped with an underwater propeller (stirring effect), the energy consumption is 1KW / 1000m 3 (2) Aeration tank (aerobic tank), tank size: 20×10×5.5m, effective volume: 1000m 3 , (3) The surface load of the secondary settling tank is 0.5m 3 / m 2 / h design, the size is Φ10×5.5m, and the effective volume is 3533m 3 . The system is inoculated with sludge 10g·L at one time -1 .

[0028] The waste methanol produced by the loc...

Embodiment 2

[0030] The concentration of nitrate in groundwater in a certain area is as high as 100mg·L -1 About, the COD value is 10mg·L -1 ~50mg·L -1 , pH 6.0-9.0, and there are many small sugar or starch factories in this area, and the production wastewater is mostly biodegradable, which is suitable as a carbon source for nitrate denitrification. Similarly, ethanol, phthalic acid, acetic acid or Glucose can all achieve the same purpose. Applying the present invention to enter nitrate groundwater for treatment also solves the problem of discharge of production waste water up to standard in many enterprises.

[0031] The average COD of wastewater discharged from a sugar production plant is 4000mg·L -1 , water volume is 500m 3 d -1 . An anoxic pool / aeration pool system is established in the factory area, and the main structure has an anoxic pool 500m 3 , aeration tank 1200m 3 , the secondary settling tank is 0.75m according to the surface load 3 / m 2 / h design, the volume is 3500...

Embodiment 3

[0034] Establish a laboratory simulation test device, anoxic tank 25L, aerobic tank 50L, secondary sedimentation tank 500L. Influent nitrate concentration is 100mg·L -1 , COD value is 10mg·L -1 ~50mg·L -1 , pH 6.0~9.0, water volume from 0.25m 3 d -1 Gradually increase to 1.5m 3 d -1 , the nitrate load in the anoxic pool was changed from 0.5gNO 3 -N·L -1 d -1 Increased to 3.0gNO 3 -N·L -1 d -1 , the sludge reflux ratio is 1.0.

[0035] When the nitrate load in the anoxic pool is less than or equal to 1.0gNO 3 -N·L -1 d -1 , when the aeration rate is 15m 3 / min / 1000m 3 When the aeration tank sludge sinks to the bottom, it obviously cannot meet the needs of the present invention; the aeration air volume is at 20m 3 / min / 1000m 3 , the effluent COD is maintained at 6mg·L -1 Around; continue to increase the air volume to 25m 3 / min / 1000m 3 , the effluent COD did not change significantly. That is, when the nitrate load in the anoxic pond is less than 1.0gNO 3 -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com