Vertical charging method for roasting carbon blocks and charging die thereof

A vertical technology for roasting carbon, which is applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., and can solve the problems of dead corners, corner drop, and edge drop of roasted carbon blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

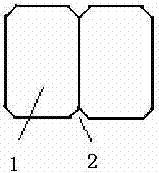

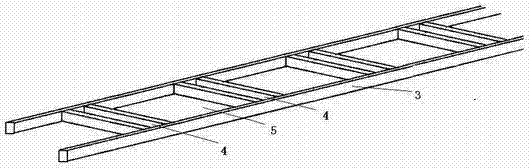

[0013] to combine figure 1 , first group the raw carbon blocks, specifically seven raw carbon blocks as a group, arranged in a straight line, every two raw carbon blocks 1 corners form a lead angle 2; put stuffing; combine figure 2 , place the furnace loading mold 3 on the filling material, lay the filling material again in the filling material filling area 4 of the furnace loading mold 3, then pull out the furnace loading mold 3, and place the carbon block placement area at the interval between the filling materials laid again 5. Place the grouped raw carbon blocks for furnace loading and roasting.

[0014] The furnace loading mold 3 used in this embodiment is grid-shaped, and the large and small grids are arranged alternately in sequence. The large grid is the carbon block placement area 5 , and the small grid is the filler filling area 4 . By laying the filler again in the filler filling area 4, the filler is effectively filled to the corners of the end of the carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com