Method, product and application for preparing glycosylated zein by extrusion-ultrasonic combination

A technology of zein and glycosylation reaction, applied in the direction of texturization, plant protein processing, etc., can solve the problem of increasing the probability of collision between protein and sugar, unfavorable applications, ranging from tens of hours to several days or even Several weeks and other problems to achieve the effect of speeding up the grafting reaction, realizing waste utilization, and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

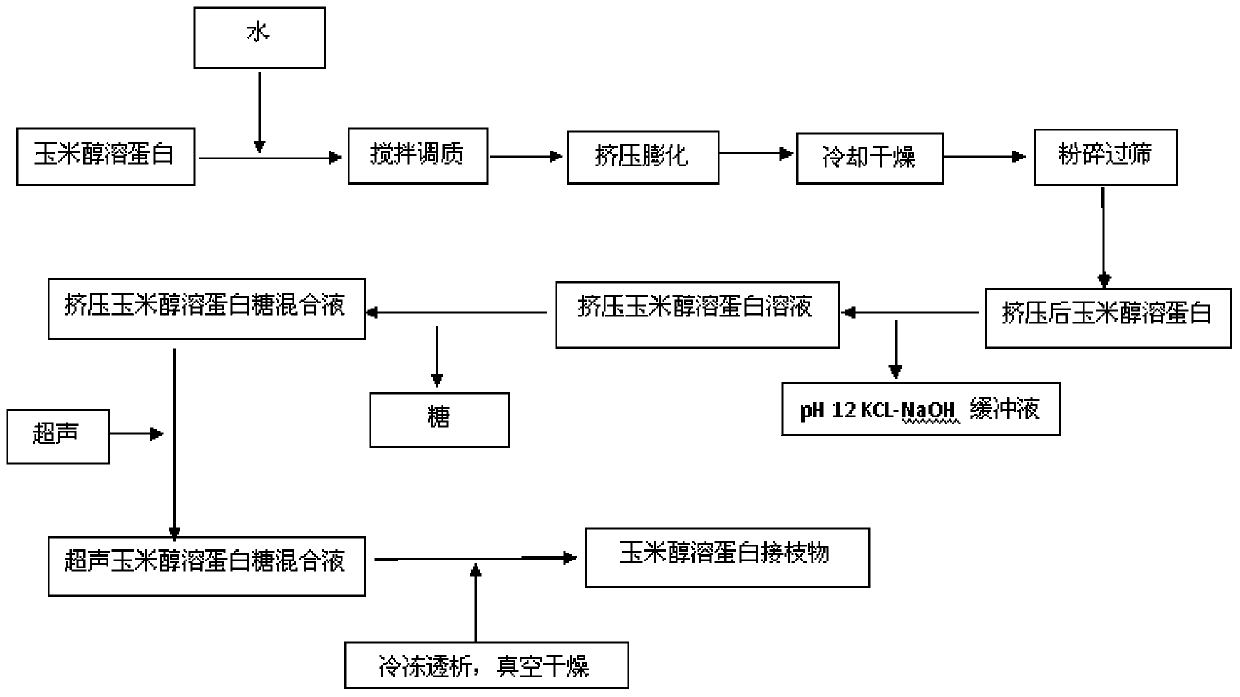

Method used

Image

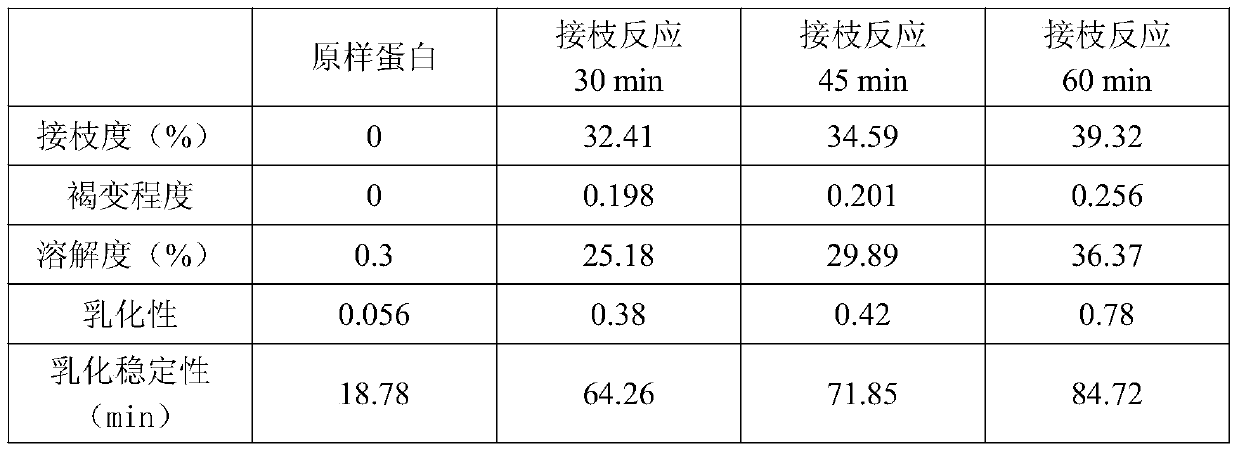

Examples

Embodiment 1

[0028] 1) Mix zein and distilled water evenly, and extrude and expand the zein with an extrusion extruder. The screw speed of the extrusion extruder is 60r / min, the temperature of the sleeve is 60°C, and the moisture content of the material is 15%, after obtaining the puffed product, dry it at 40°C for 2 hours, crush it with a high-speed universal pulverizer and pass it through a 80-mesh sieve;

[0029] 2) The zein obtained in step 1) was prepared into a protein solution with a protein concentration of 2 mg / mL with a pH 12 KCL-NaOH buffer solution, and stirred at room temperature for 25 min;

[0030] 3) Add glucose to the protein solution in step 2) at a mass ratio of 1:0.5, stir for 20 minutes, put the mixture in an ultrasonic cell pulverizer for ultrasonic-assisted glycosylation, ultrasonic conditions: temperature 55°C, time 30 minutes , Ultrasonic power 120W;

[0031] 4) After the glycosylation reaction is completed, the mixture is cooled to room temperature in an ice bath...

Embodiment 2

[0033] 1) Mix zein and distilled water evenly, and use an extrusion extruder to extrude and expand the zein. The screw speed of the extrusion extruder is 120r / min, the temperature of the sleeve is 80°C, and the moisture content of the material is 21%, after obtaining the puffed product, dry it at 40°C for 2 hours, crush it with a high-speed universal grinder and pass it through a 80-mesh sieve;

[0034] 2) The zein obtained in step 1) was prepared into a protein solution with a protein concentration of 6 mg / mL with KCL-NaOH buffer solution of pH 12.2, and stirred at room temperature for 30 min;

[0035] 3) Add glucose to the protein solution in step 2) at a mass ratio of 1:2, stir for 22 minutes, put the mixture in an ultrasonic cell pulverizer for ultrasonic-assisted glycosylation, ultrasonic conditions: temperature 65°C, time 45 minutes , Ultrasonic power 160W;

[0036] 4) After the glycosylation reaction was completed, the mixture was cooled to room temperature in an ice b...

Embodiment 3

[0038] 1) Mix zein and distilled water evenly, and use an extrusion extruder to extrude and expand the zein. The screw speed of the extrusion extruder is 180r / min, the temperature of the sleeve is 100°C, and the moisture content of the material is 27%, after obtaining the puffed product, dry it at 40°C for 2 hours, crush it with a high-speed universal pulverizer, and pass it through a 80-mesh sieve;

[0039] 2) The zein obtained in step 1) was prepared into a protein solution with a protein concentration of 10 mg / mL with KCL-NaOH buffer solution of pH 12.5, and stirred at room temperature for 35 min;

[0040] 3) Add maltodextrin to the protein solution in step 2) at a mass ratio of 1:3, stir for 25 minutes, put the mixture in an ultrasonic cell pulverizer for ultrasonic-assisted glycosylation, ultrasonic conditions: temperature 75°C, Time 60min, ultrasonic power 200W;

[0041] 4) After the glycosylation reaction was completed, the mixture was cooled to room temperature in an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com