Aviation kerosene production method

A technology for aviation kerosene and diesel oil, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve problems such as increasing the complexity of the process, and achieve low sulfur and nitrogen content, high hydrogen consumption, and high utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

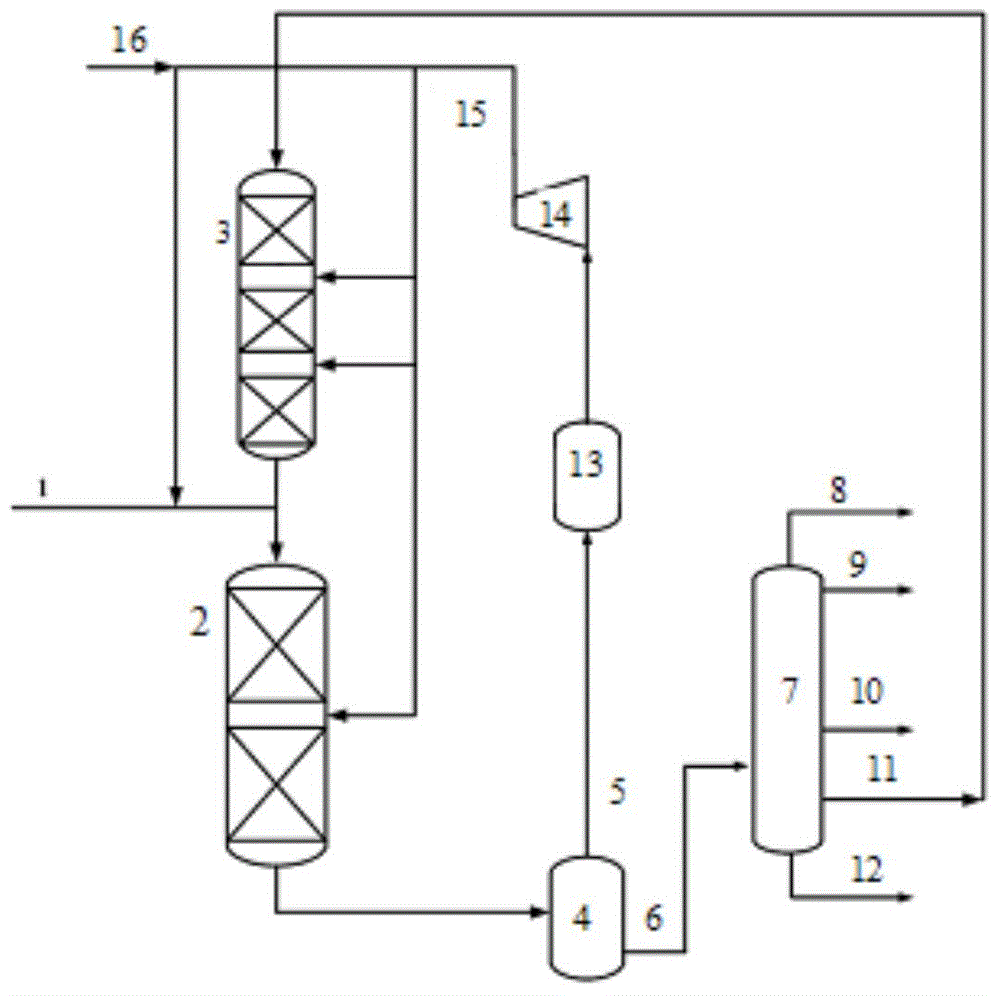

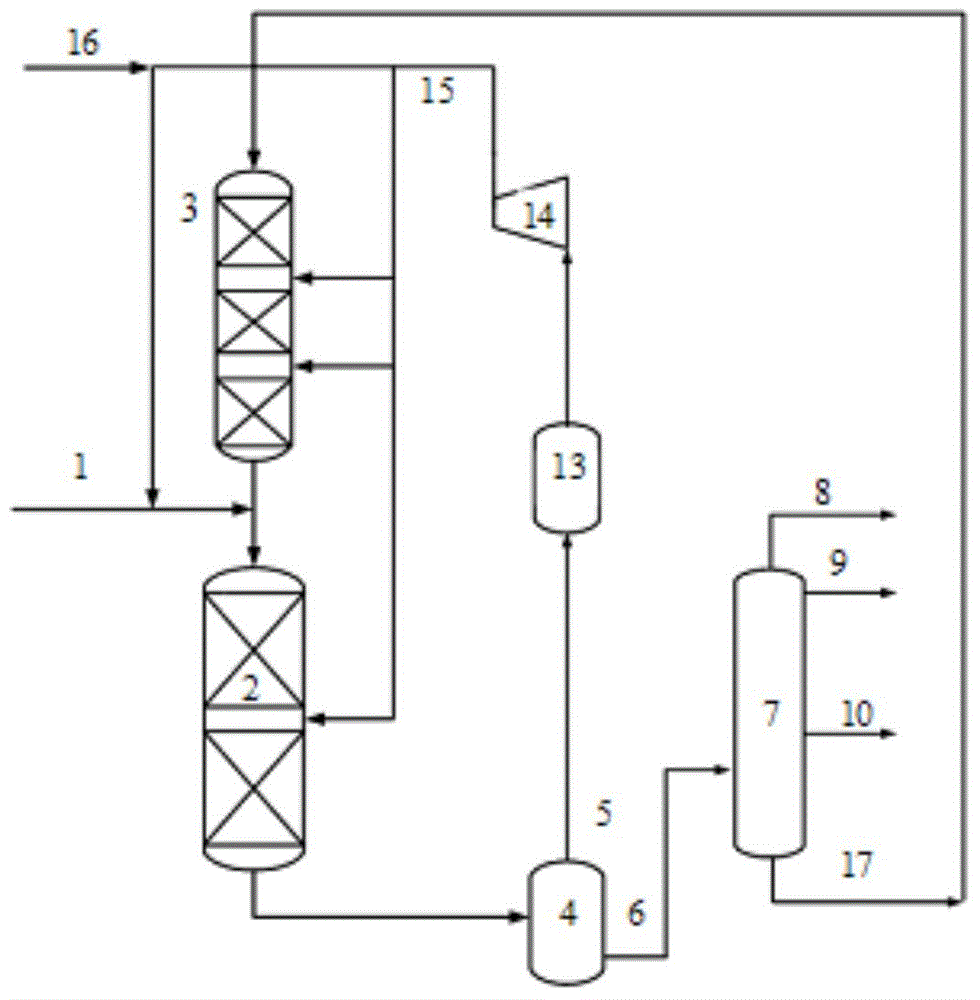

Method used

Image

Examples

Embodiment 1

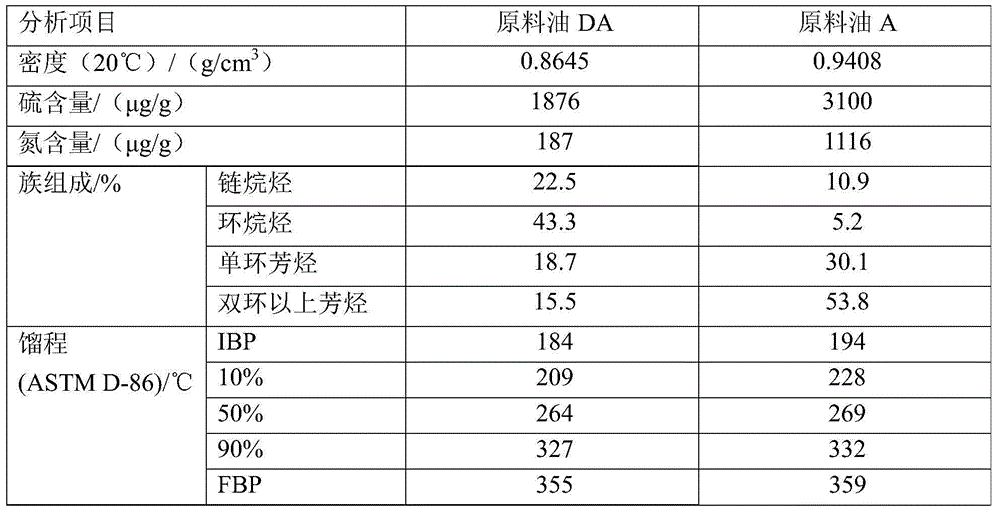

[0095] The feed oil A used in this example is catalytically cracked diesel oil, the properties of which are listed in Table 1.

[0096] This embodiment is carried out in two fixed-bed reactors, wherein the hydrofinishing catalyst is filled in the first fixed-bed reactor; the hydrogenation catalyst is filled in the second fixed-bed reactor sequentially based on the flow direction of the liquid feed Cracking catalysts and make-up hydrofinishing catalysts. The loading volume ratio of hydrofinishing catalyst, hydrocracking catalyst and make-up hydrofinishing catalyst is 60:40:10.

[0097] Both the hydrofinishing catalyst and the make-up hydrofinishing catalyst were prepared as follows.

[0098] With 3000 grams of SilicaGel955 commercial silica gel (U.S. DavisonChemical company product, SiO 2 The content is 99.8% by weight) and 75 grams of scallop powder are evenly mixed, and then mixed with 84 milliliters of nitric acid (concentration 65-68 weight percent, analytically pure, pro...

Embodiment 2

[0108] Adopt the same method as Example 1 to produce aviation kerosene, the difference is that the hydrofinishing catalyst used and the added hydrofinishing catalyst used are prepared by the following method:

[0109] With 200 ml of dilute ammonia solution containing 21.9 g of ammonium paramolybdate (NH 3 The concentration is 10% by weight) to impregnate 200 grams of silica carrier S for 2 hours, then dry at 120° C. for 4 hours, and then bake at 460° C. for 4 hours to obtain a molybdenum-containing carrier loaded with molybdenum oxide. Then, the molybdenum-containing support was impregnated with 156 ml of an aqueous solution containing 13.3 g of cobalt nitrate and 4.4 g of nickel nitrate for 2 hours, followed by drying at 120° C. for 4 hours, and then at 470° C. for 4 hours to obtain the hydrofinishing catalyst. The composition of the catalyst was determined by X-ray fluorescence spectrometry, wherein, MoO 3 The content of NiO is 8.0% by weight, the content of NiO is 0.6% by ...

Embodiment 3

[0112] Adopt the same method as Example 1 to produce aviation kerosene, the difference is that the hydrocracking catalyst used is prepared by the following method:

[0113] With 185.7 grams of pseudo-boehmite (the product of Changling Branch of China Petrochemical Corporation, the dry basis is 70% by weight) and 93.3 grams of USY zeolite (the product of Changling Branch of China Petrochemical Corporation, the unit cell constant is 24.50 angstroms, crystallinity is 88%, sodium oxide content is 0.8% by weight, and dry basis is 75% by weight) mixed, extruded into a trilobal bar with a circumscribed circle diameter of 1.6 mm, and the wet bar is dried at 120 ° C for 3 hours, then Baking was carried out at 450° C. for 4 hours to obtain a carrier DZ1.

[0114] With 88 ml of ammonium metatungstate (in WO 3 meter, the concentration is 422 g / L), ammonium molybdate (as MoO 3 24.3 g / L) and nickel nitrate (69.8 g / L in terms of NiO) mixed aqueous solution impregnated 100 g of carrier DZ1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Cell constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com