Water-penetrating cooling system

A technology of water-penetrating cooling and water-penetrating cooler is applied in workpiece cooling device, workpiece surface treatment equipment, metal rolling, etc. It can solve the problems of affecting the cooling effect of water-penetrating cooling, hindering heat transfer, etc. The effect of strengthening effective contact and improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

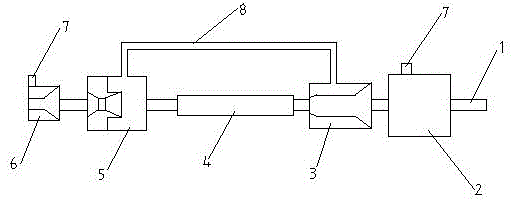

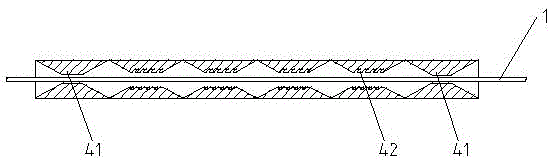

[0020] Such as figure 1 and 2 As shown, a water-through cooling system includes a guide device 2, a water-through cooler 3, a conduit 4, a water eliminator 5, and a water blocker 6. The water-through cooler 3 has a water inlet and a nozzle, and the jet flow of the nozzle The included angle between the direction and the horizontal line is 20±1 degrees. The water eliminator 5 has a water outlet, and a return pipe 8 is provided between the water outlet and the water inlet. The conduit 4 has 6 contraction sections, and the contraction sections at both ends are supporting contraction sections. 41. The contraction section in the middle is a spiral contraction section 42, the inner diameter of the support contraction section 41 is smaller than the inner diameter of the spiral contraction section 42, and the inner wall of the spiral contraction section 42 has a left-handed line for forcing the water flow to rotate.

[0021] In addition, the helix of the helical constriction section 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com