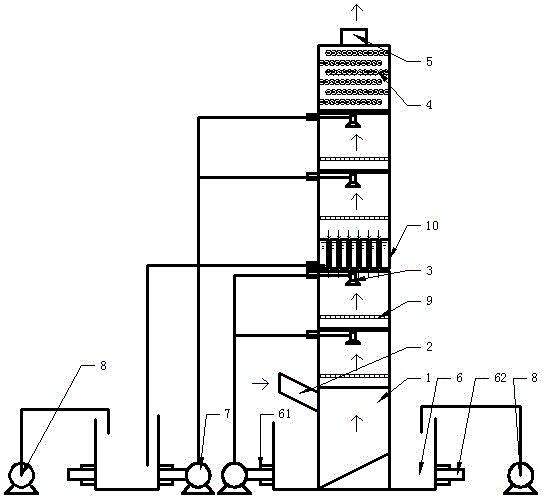

Device and method for simultaneously removing sulfur and mercury through paper-pulping black liquor

A technology for pulping black liquor and slurry, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems affecting enterprise development, high desulfurization operation costs, and no accurate data on the removal rate of polluted gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

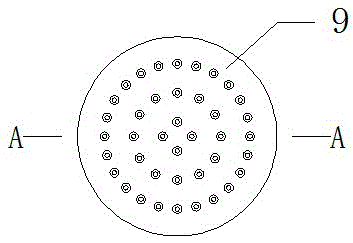

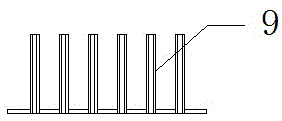

Method used

Image

Examples

Embodiment 1

[0109] Using the wheat straw pulping black liquor synergistic desulfurization and mercury removal device (authorization number: 204220023U) recorded in the present invention and the authorized utility model patent respectively, the desulfurization and mercury removal experiments were carried out under the same conditions, and the experimental results were compared.

[0110] The black liquor from a paper mill was selected, and the tested components were: bromide 0.5%, chloride 3%, sulfate substances 2%, carbonate substances 3%, sulfide 0.5%, lignin compounds 8%, NaOH concentration 2%, sucrose 0.6%, dimethyl sulfone 2%, sodium gluconate 1.0%;

[0111] The flue gas comes from a thermal power plant, the flue gas SO 2 Concentration = 2700mg / m 3 ; Mercury concentration = 48ug / m 3 ;

[0112] According to SO 2 Adjust the working parameters with the concentration of Hg: cycle L / G=13L / m 3 ; Black liquor volume = 38L; slurry temperature = 12°C; air temperature = 13°C; superficial ga...

Embodiment 2

[0117] The black liquor is the black liquor of a certain paper mill described in Example 1, and the flue gas comes from a certain thermal power plant described in Example 1. Combining charts 1 and 2, it can be seen that the black liquor composition in production is different from the optimized black liquor composition content, and needs to be adjusted. Use NaBr to simulate bromide in black liquor, use NaCl to simulate chloride in black liquor, use Na 2 SO 4 Simulated sulfate substances in black liquor, with Na 2 CO 3 To simulate carbonates in black liquor, use Na 2 S simulates the sulfide in the mercury removal black liquor, uses sodium lignosulfonate to simulate the lignin compound in the pulping black liquor, conducts conditioning and tempering according to the composition content in Table 2, and then treats the flue gas.

[0118] According to SO 2 Adjust the working parameters with the concentration of Hg: cycle L / G=13L / m 3 ; Black liquor volume=38L; Slurry temperatur...

Embodiment 3

[0121] The black liquor adopts the black liquor after quenching and tempering in Example 2, and the flue gas comes from a certain boiler, SO 2 Concentration = 5000mg / m 3 , mercury concentration = 90μg / m 3 . According to SO 2 Adjust the working parameters with the concentration of Hg: cycle L / G=14L / m 3 ; Black liquor volume = 38L; slurry temperature = 11°C; air temperature = 12°C. The superficial gas velocity is 0.3m / s. It is obtained that the desulfurization efficiency=98.3%, the mercury removal efficiency=78.5%, and the emission can reach the standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com