Preparation method of battery diaphragm and battery membrane

A battery diaphragm and base film technology, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problem of unsatisfactory battery performance, increased tortuosity of the pore diameter of the composite diaphragm, and inconsistent porosity of the two-layer coating and other problems, to achieve the effect of ensuring heat resistance, good liquid absorption rate, and good liquid retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

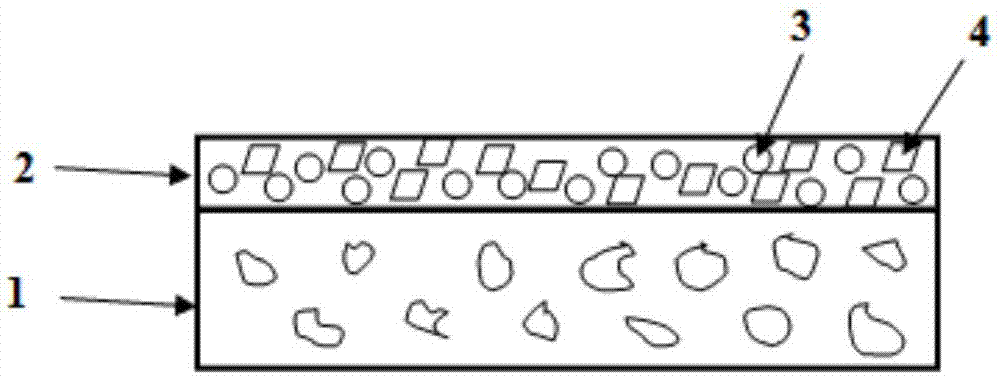

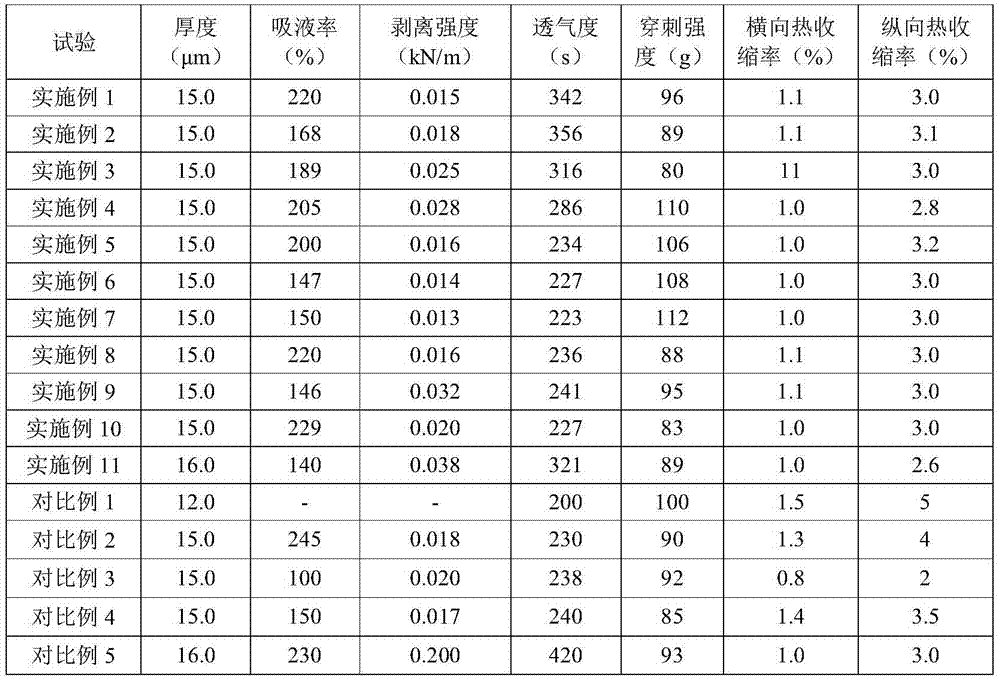

[0032] The battery separator in this example is figure 1 As shown, it includes a base film 1 and a coating 2 coated on the surface of the base film. The coating 2 contains organic particles 3 and irregular inorganic particles 4 . In this example, a 12 μm polypropylene microporous membrane is used as the base membrane, the inorganic particles are alumina particles with a D50 of 700 nm, the organic particles are copolymer particles of vinylidene fluoride and hexafluoropropylene with a particle size of 200 nm, and deionized water is used as the solvent. and N-methylpyrrolidone, the water-soluble dispersant adopts sulfonate, and the wetting agent adopts ethanol.

[0033] The preparation method of the battery separator of this example is as follows:

[0034] Weigh 25.2g inorganic particles, 10.8g organic particles, 0.72g water-soluble dispersant, 3.5g wetting agent, 1.2g viscosity modifier, 88.1g deionized water, 1.5g organic solvent, and put all the materials into the mixer , 20...

Embodiment 2

[0045] The battery diaphragm of this example is the same as that of Example 1, except that the inorganic particles use boehmite particles with a D50 of 710nm, and the organic particles use copolymer particles of acrylonitrile and methyl methacrylate with a particle size of 500nm, replacing the inorganic particles of Example 1. The amount of particles and organic particles, inorganic particles and organic particles is the same as in Example 1, the preparation method is the same as in Example 1, and the remaining components and amounts of the slurry are the same as in Example 1. A battery separator was prepared by the same method as in Example 1.

[0046] Similarly, the same test method was used to test the battery separator of this example, and the test results are shown in Table 1.

Embodiment 3

[0048] The battery diaphragm of this example is the same as that of Example 1, except that the inorganic particles use alumina particles with a D50 of 750nm, and the organic particles use polymethyl methacrylate particles with a particle size of 300nm, replacing the inorganic particles and organic particles of Example 1. The amount of particles and organic particles is the same as in Example 1, the preparation method is the same as in Example 1, and the remaining components and amounts of the slurry are the same as in Example 1. A battery separator was prepared by the same method as in Example 1.

[0049] Similarly, the same test method was used to test the battery separator of this example, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com