Cyclic quaternary ammonium salt electrolyte, preparation method and application therefor

A quaternary ammonium salt and electrolyte technology, which is used in the manufacture of hybrid capacitor electrolytes and hybrid/electric double layer capacitors, etc., can solve the problems of small processing capacity of chromatography columns, inability to reuse solvents, and low efficiency, and achieve a simple and easy purification method. line, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

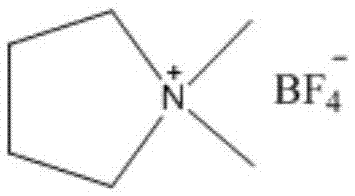

[0037] 1: Preparation of N,N-dimethylpyrrolidinium tetrafluoroborate

[0038] (1), first add 200g of sodium hydroxide to 1333g of high-purity water to prepare a 13% sodium hydroxide aqueous solution, and inhale in a 5L stainless steel high-pressure reactor, then inhale 630g of 1,4 dichlorobutane under stirring , and finally 236.5 g of dimethylamine was introduced; the reaction solution was stirred for 30 minutes until it was uniform, and the electric heating was turned on to raise the temperature to 90°C for 10 hours of reaction.

[0039] (2) The above synthesis reaction solution was vacuum dehydrated on a rotary evaporator at 110°C to a powder solid mixture of 968g;

[0040] (3) Add 968 g of absolute ethanol to the above solid mixture, stir for 60 minutes, and then filter to obtain 1600 g of an ethanol solution of N,N-dimethylpyrrolidinium chloride salt;

[0041] (4) Add 525 g of ammonium tetrafluoroborate to the above-mentioned ethanol solution of N,N-dimethylpyrrolidinium ...

Embodiment 2

[0052] 1: Preparation of N-ethyl-N-methylpyrrolidinium tetrafluoroborate

[0053] (1), first add 280g of potassium hydroxide to 2154g of high-purity water to prepare a concentration of 11.5% potassium hydroxide aqueous solution, and inhale in a 5L stainless steel autoclave, then inhale 1,4 dibromobutane 1070g under stirring , and finally 310g of N-ethylmethylamine was introduced; the reaction solution was stirred for 30 minutes until uniform, and the electric heating was turned on to raise the temperature to 80°C for 8 hours. During the reaction, the pressure was controlled at 0.1MPa~1.0MPa; Liquid 3800g;

[0054] (2) The above synthesis reaction solution was vacuum dehydrated on a rotary evaporator at 110° C. to 1335 g of a powder solid mixture;

[0055] (3), add 1335g of anhydrous acetonitrile to the above solid mixture, after stirring for 60min, filter to obtain 2300g of acetonitrile solution of N-ethyl-N-methylpyrrolidinium bromide;

[0056] (4) Add 525 g of ammonium tet...

Embodiment 3

[0067] 1: Preparation of N-propyl-N-methylpiperidinium tetrafluoroborate

[0068] (1), first adding 345g of salt of wormwood to 1916g of high-purity water and being mixed with the potassium carbonate aqueous solution of 15% concentration, and inhaling in the 5L stainless steel autoclave, then inhaling 1,5 dichloropentane 700g under the state of stirring, finally Pass in 383g of N-methyl n-propylamine; stir the reaction solution for 30min until uniform, turn on the electric heating and raise the temperature to 100°C for 8 hours, and control the pressure at 0.1MPa~1.0MPa during the reaction process; release 3200g of synthetic reaction solution after returning to normal temperature;

[0069] (2) The above synthetic reaction solution was vacuum dehydrated on a rotary evaporator at 110°C to 1257g of a powder solid mixture;

[0070] (3), add 1257g of anhydrous ethyl acetate to the above solid mixture, after stirring for 60min, filter to obtain 2300g of ethyl acetate solution of N-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com