Reactive powder concrete pipe column for ocean engineering

A technology of active powder and concrete columns, which is applied in the direction of basic structure engineering, construction, sheet pile walls, etc., can solve the problems of corrosion damage of RPC components, strong chloride ion permeability, and affecting the appearance of components, etc., to achieve outstanding corrosion resistance and durability Excellent corrosion performance and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

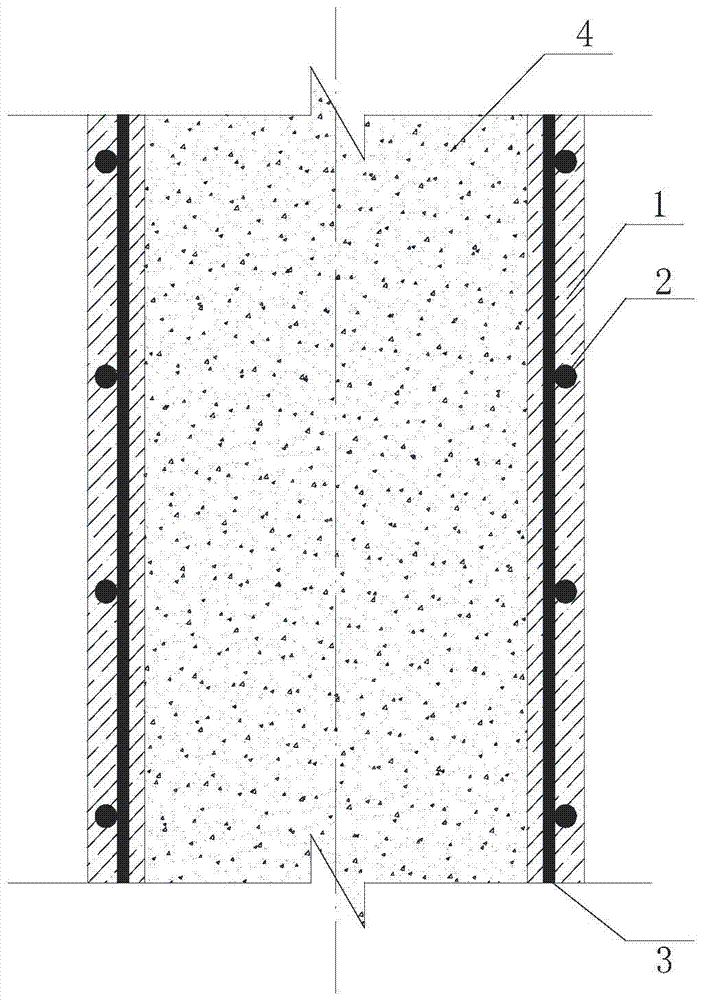

[0020] As shown in the accompanying drawings, the present invention is an active powder concrete sleeve concrete column, comprising an active powder concrete sleeve (1), stirrups (2), longitudinal bars (3), concrete columns (4), stirrups (2 ), the longitudinal bars (3) are arranged in the active powder concrete casing (1), and it is characterized in that the stirrups (2), the longitudinal bars (3) are closed fiber reinforced plastic stirrups (2) and fiber reinforced plastic longitudinal bars respectively ribs (3), and corrosion-resistant short fibers are added to the active powder concrete of the casing (1), such as figure 1 and figure 2 shown. During implementation, first, according to the design requirements, the closed fiber-reinforced plastic stirrups (2) and fiber-reinforced plastic longitudinal bars (3) are made into FRP cages, and placed in the mold for making the prefabricated active powder concrete casing (1) Inside; RPC is mixed with stainless steel fiber and synt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com