Antibacterial dry cleaning agent for clothing

A dry-cleaning agent and clothing technology, which is applied in the field of daily chemicals, can solve the problems of dry-cleaning agent residues on clothes, no sterilization and antibacterial treatment, etc., and achieve the effect of excellent cleaning power, fast washing, and pleasant fragrance of clothes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A kind of antibacterial dry cleaning agent for clothes of the present invention comprises the following raw materials in parts by weight: 20 parts of polyoxyethylene lauryl ether, 1 part of citric acid, 5 parts of protease, 5 parts of polyethylene glycol, octadecyl dihydroxyethyl 10 parts of betaine, 1 part of saponin powder, 1 part of oxalic acid, 5 parts of triethanolamine, 1 part of castor oil, 1 part of sorbitol, 0.1 part of jasmine essence, 30 parts of deionized water.

Embodiment 2

[0014] A kind of antibacterial dry cleaning agent for clothes of the present invention comprises the following raw materials in parts by weight: 25 parts of polyoxyethylene lauryl ether, 3 parts of citric acid, 7 parts of protease, 8 parts of polyethylene glycol, octadecyl dihydroxyethyl 15 parts of betaine, 3 parts of saponin powder, 2 parts of oxalic acid, 8 parts of triethanolamine, 3 parts of castor oil, 2 parts of sorbitol, 0.5 parts of jasmine essence, 40 parts of deionized water.

Embodiment 3

[0016] A kind of antibacterial dry cleaning agent for clothes of the present invention comprises the following raw materials in parts by weight: 30 parts of polyoxyethylene lauryl ether, 5 parts of citric acid, 10 parts of protease, 10 parts of polyethylene glycol, octadecyl dihydroxyethyl 20 parts of betaine, 5 parts of saponin powder, 5 parts of oxalic acid, 10 parts of triethanolamine, 5 parts of castor oil, 5 parts of sorbitol, 1 part of jasmine essence, 50 parts of deionized water.

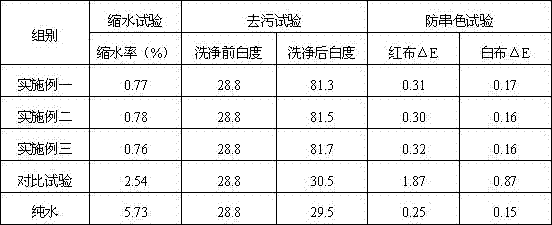

[0017] The dry cleaning agent obtained in Examples 1 to 3 and the commercially available dry cleaning agent (tetrachloroethylene) were subjected to a comparative test of shrinkage, stain removal and anti-cross-color performance. The specific test method was carried out as described below, and the test results are shown in Table 1.

[0018] (1) Shrinkage comparison test: Use the wool shrinkage sample cloth 300╳300mm required by the national standard MLBT4288-2008 as the test sample cloth, soak ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com