A controllable batch preparation method of organic/inorganic hybrid Janus particles

A particle-inorganic technology, applied in the field of controllable batch preparation of organic/inorganic hybrid Janus particles, can solve the problem of difficult to achieve strict division of chemical composition and fine control of microstructure, inability to obtain sub-micron or even nano-scale materials, lack of Janus particle fine control method, etc., to achieve high industrial application potential, realize batch industrial production, and facilitate multi-functionalization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

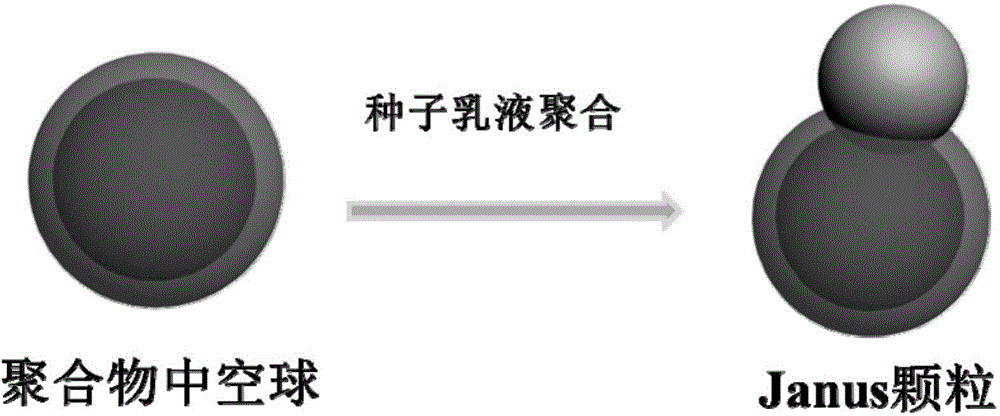

[0050] Based on the present invention, the present invention provides organic / inorganic hybrid Janus particles with separated organic and inorganic parts and methods for their preparation, such as figure 1 As shown, it is a schematic diagram of the preparation process of organic / inorganic hybrid Janus particles prepared by the present invention. The organic / inorganic hybrid Janus particles provided by the present invention are prepared by emulsion polymerization. The method comprises the steps of:

[0051] 1) dispersing polymer hollow spherical particles in water to obtain seed emulsion;

[0052] 2) Add the silane coupling agent emulsion to the seed emulsion, carry out the polymerization reaction under mechanical stirring, and produce phase separation to obtain the Janus particle emulsion; the silane coupling agent emulsion includes the silane coupling agent monomer and the polymerization initiator .

[0053] 3) The Janus particle emulsion obtained in step 2) is spray-dried ...

Embodiment 1

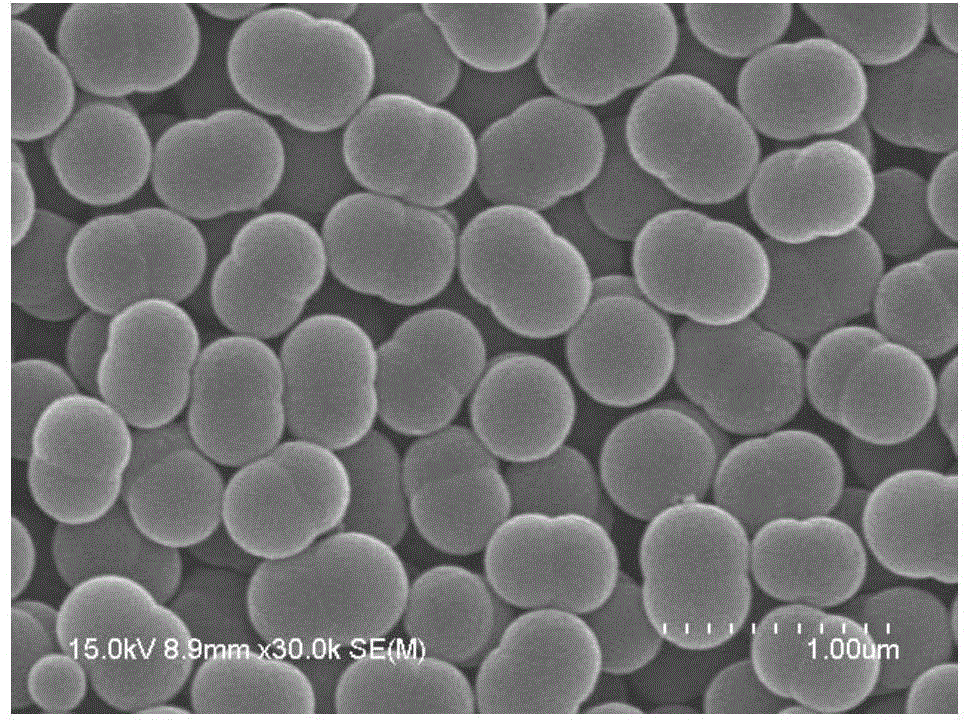

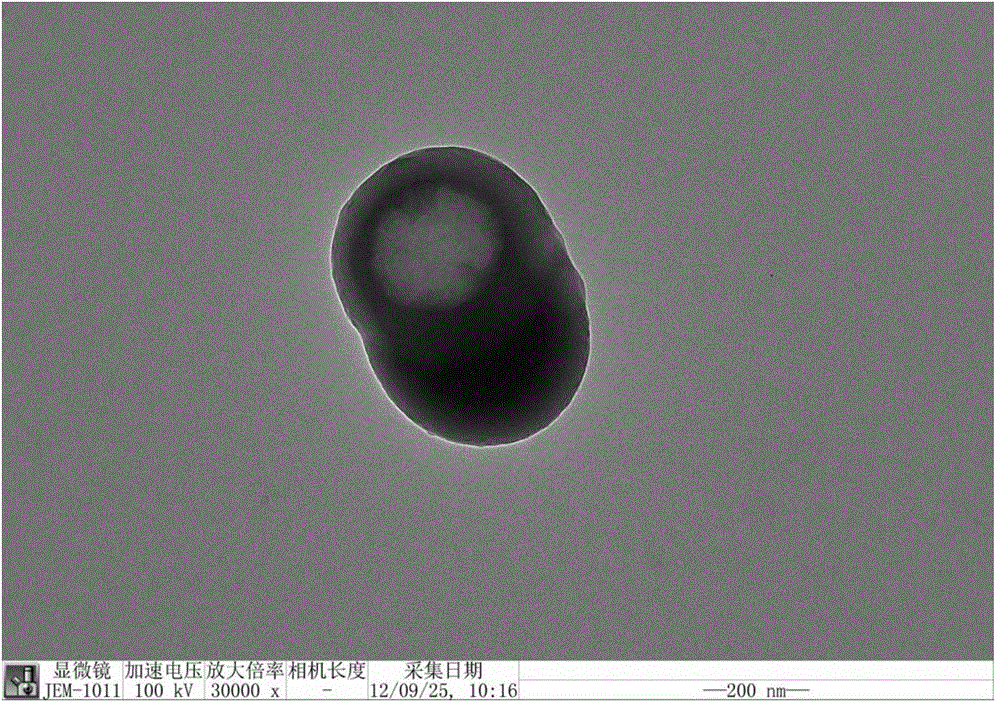

[0057] Add 20 g of deionized water to 2.667 g of linear polystyrene (PS) hollow sphere emulsion with a solid content of 37.5%, and mechanically stir to form a uniform seed sphere emulsion (with a solid content of 4.41%). Adopt 2.0g oil-soluble silane coupling agent monomer (3-(methacryloxy) propyltrimethoxysilane (MPS)), initiator (1% potassium persulfate solution (KPS)) 2.0g, 0.02g Surfactant (sodium dodecyl sulfate (SDS)) and 10g deionized water ultrasonically form a homogeneous silane coupling agent monomer emulsion (silane coupling agent monomer 14.2%, initiator 1.42‰; surfactant 1.42‰, The balance is water). The rotation speed is 400rpm and mechanical stirring is performed, the seed emulsion is heated to 70°C, and the above-mentioned silane coupling agent monomer emulsion is added to the seed ball emulsion at a speed of 2.5rpm with a mechanical peristaltic pump. Under continuous mechanical stirring, the whole system was polymerized at 70° C. for 24 hours. At the beginni...

Embodiment 2

[0059] Add 10 g of deionized water to 2.667 g of linear polystyrene (PS) hollow sphere emulsion with a solid content of 37.5%, and mechanically stir to form a uniform seed sphere emulsion (with a solid content of 4.41%). Adopt 1.0g oil-soluble silane coupling agent monomer (3-(methacryloyloxy) propyltrimethoxysilane (MPS)), initiator (1% potassium persulfate solution (KPS)) 2.0g, surface activity Agent (sodium dodecyl sulfate (SDS)) 0.02g and 10g deionized water ultrasonically form a homogeneous monomer emulsion (silane coupling agent monomer 14.2%, initiator 1.42‰; surfactant 1.42‰, the balance is water ). The rotation speed is 400rpm and mechanical stirring is performed, the seed emulsion is heated to 70° C., and the silane coupling agent monomer emulsion is added to the seed ball emulsion at a speed of 2.5 rpm with a mechanical peristaltic pump. Under continuous mechanical stirring, the whole system was polymerized at 70° C. for 24 hours to obtain a silica / polystyrene Janu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com