Sunscreen cream and preparation method thereof

A sunscreen and sunscreen technology, applied in the field of daily chemicals, can solve the problems of increased epidermal water evaporation, telangiectasia and congestion, adverse effects on the skin, etc., and achieve the effect of non-irritating, non-allergic, and excellent absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a preparation method of the sunscreen according to the present invention, comprising: a step of mixing the components of the sunscreen.

[0050] According to the method of the present invention, comprise the following steps:

[0051] 1) Grinding after mixing the physical sunscreen and liquid oil to obtain a powder;

[0052] 2) Add the ground powder, oil phase thickener, emulsifier, antioxidant, chemical sunscreen, oil-soluble preservative into the emulsification pot, stir and heat to 80-85°C to dissolve;

[0053] 3) Add deionized water, humectant, complexing agent, crosslinking agent, and inorganic salt into the water phase stirring pot, stir and heat to 80-85°C and dissolve completely to obtain the water phase substance;

[0054] 4) Pump the water phase material into the emulsification pot, stir and heat to 80°C, and then cool down after homogeneous stirring.

[0055] 5) Cool down to 42-45°C, add antisensitizers, polypeptides, flav...

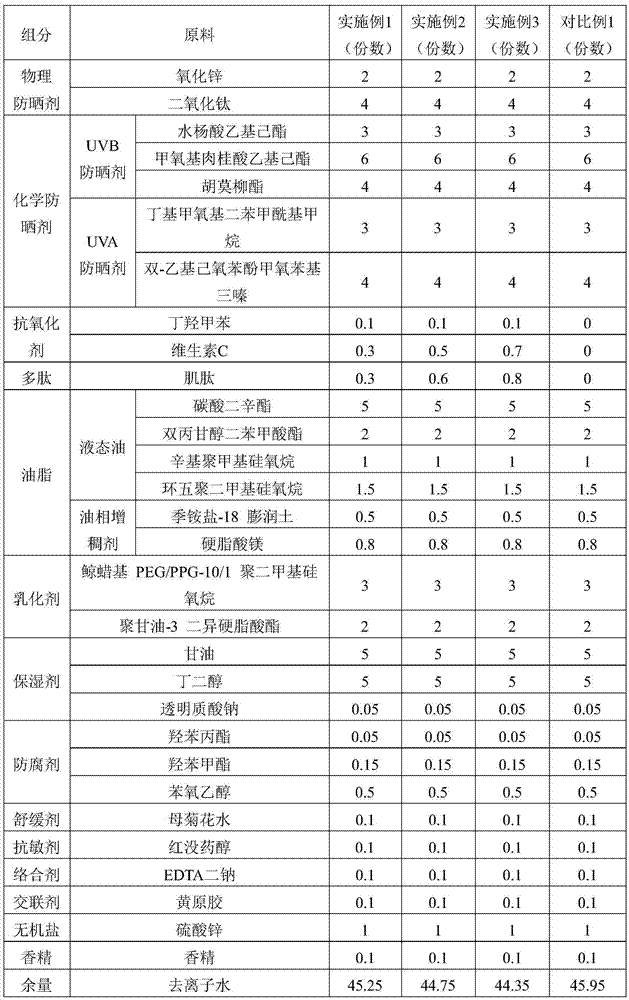

Embodiment 1-3

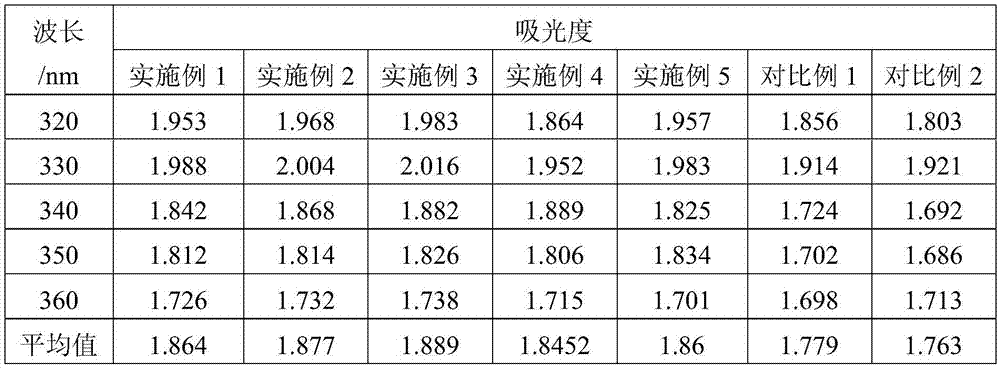

[0060] According to the content (number of parts) of each component of the sunscreen of Example 1-3 in the following table 2, and according to the steps of the following preparation method, sunscreen I-III is prepared, and the ultraviolet absorbance of sunscreen I-III is measured and infrared absorbance.

[0061] The preparation method is:

[0062] 1) Combine physical sunscreens (zinc oxide, titanium dioxide) with liquid oils (cyclopentamethicone, dioctyl carbonate, dipropylene glycol dibenzoate, octylmethicone) After mixing, grind finely with a colloid mill to obtain a powder.

[0063] 2) Combine the ground powder with oil phase thickener (quaternary ammonium salt-18 bentonite, magnesium stearate), emulsifier (cetyl PEG / PPG-10 / 1 polydimethylsiloxane, Polyglyceryl-3 Diisostearate), Antioxidants (Butylated Hydroxytoluene, Vitamin C), Chemical Sunscreens (UVB Sunscreens: Ethylhexyl Salicylate, Ethylhexyl Methoxycinnamate, Hu Mosalate; UVA sunscreen agent: butyl methoxy dibenz...

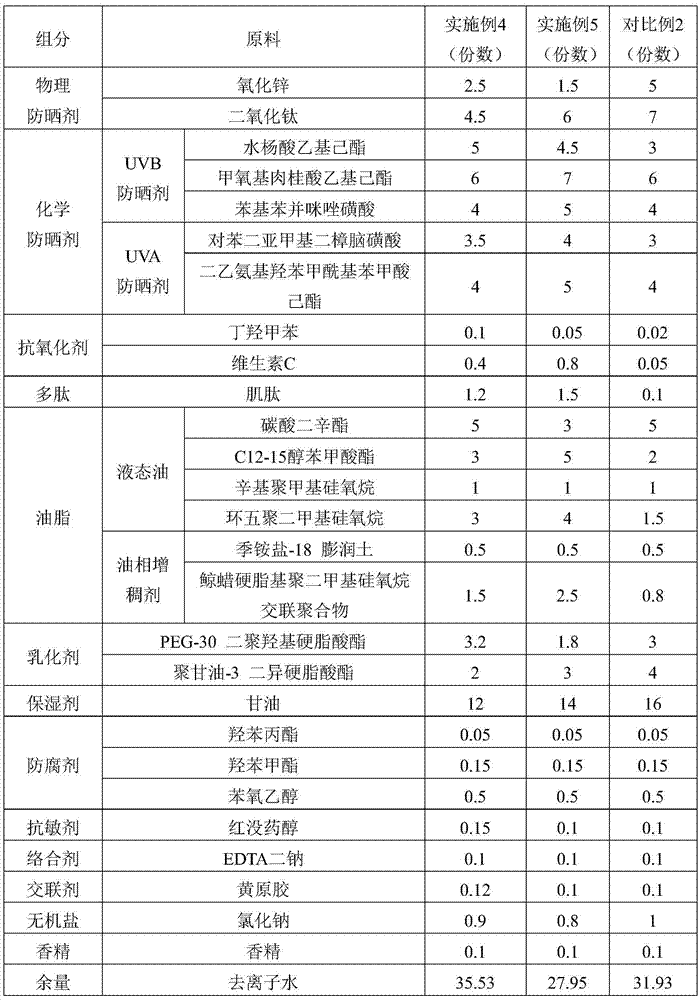

Embodiment 4-5

[0077] Sunscreens IV-V were prepared according to the content (number of parts) of each component of the sunscreen in Example 4-5 in Table 3 below, and according to the steps of the following preparation method.

[0078] The preparation method is:

[0079] 1) Mix physical sunscreens (zinc oxide, titanium dioxide) with liquid oils (dioctyl carbonate, C12-15 alcohol benzoate, caprylylmethicone, cyclopentasiloxane) Finally, grind finely with a colloid mill to obtain a powder.

[0080] 2) Combine the ground powder with oil phase thickener (quaternary ammonium salt-18 bentonite, cetearyl polydimethylsiloxane crosslinked polymer), emulsifier (PEG-30 dipolyhydroxy Stearate, Polyglyceryl-3 Diisostearate), Antioxidant (Butylated Hydroxytoluene, Vitamin C), Chemical Sunscreen (UVB Sunscreen: Ethylhexyl Salicylate, Ethyl Methoxycinnamate Hexyl hexyl ester, phenyl benzimidazole sulfonic acid; UVA sunscreens: terexylylene biscamphor sulfonic acid, diethylamino hydroxybenzoyl hexyl benzoa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com