Piston-cylinder-fixed type air pressure multi-disc friction clutch

A friction clutch, piston cylinder technology, applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve the problems of high clutch purchase, maintenance and repair costs, high maintenance and maintenance costs, and limited capacity, etc., to expand the application. Field and scope of application, reduction of manufacturing and use costs, and the effect of increasing the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

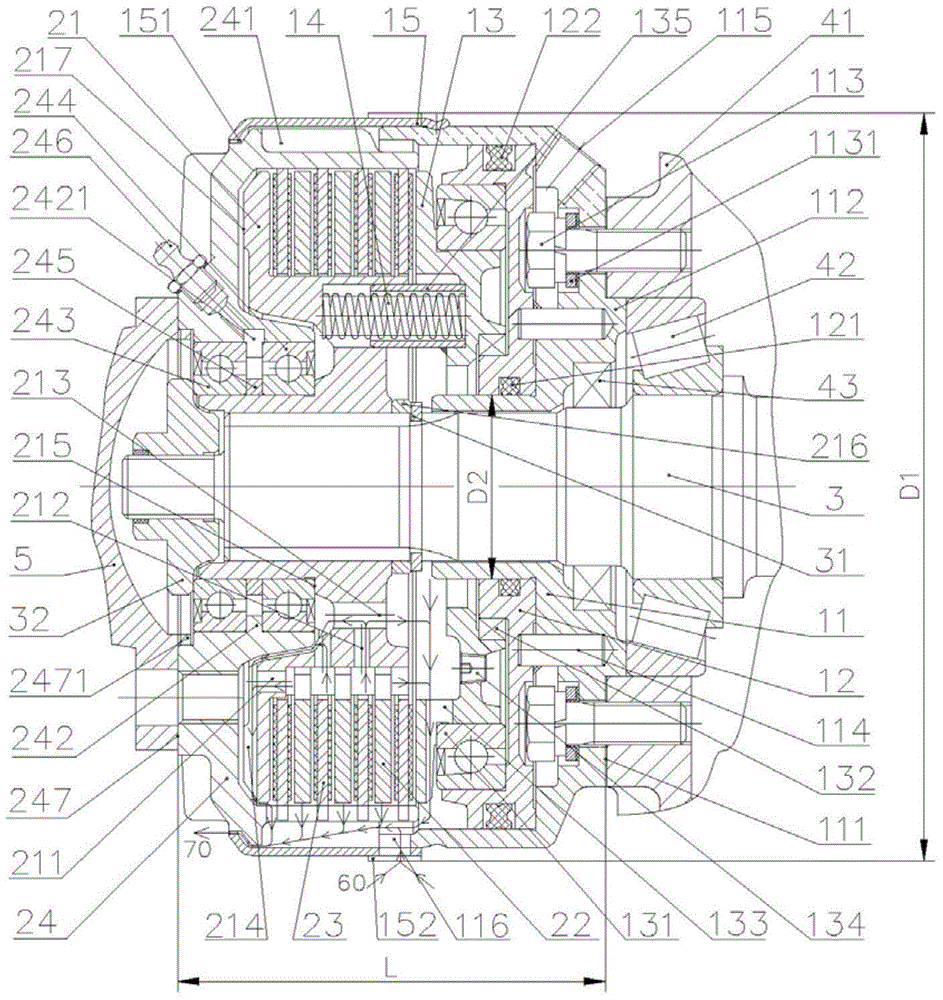

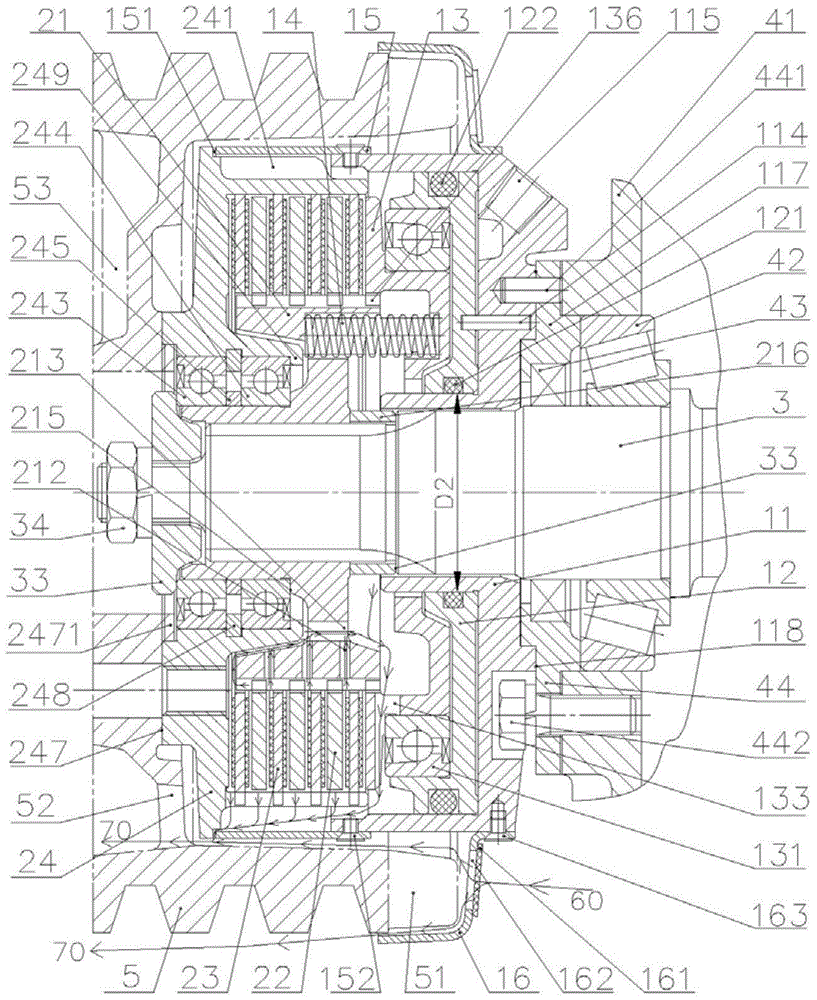

[0026]The invention discloses a piston cylinder fixed pneumatic multi-disc friction clutch, which is connected between a first transmission device and a second transmission device. The pneumatic multi-disc friction clutch includes a front section structure, a rear section structure and a connecting shaft, wherein the The first transmission device is connected to the first end of the connecting shaft through the first supporting bearing, the second transmission device is arranged at the second end of the connecting shaft, and the connecting shaft runs through the front section structure and the The rear section structure, the front section structure includes a piston cylinder, piston, pressure plate and return spring; the rear section structure includes an inner friction plate seat, a plurality of inner friction plates, a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com