Preparation method for high-porosity silver electrode

A silver electrode, porosity technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as surface bending, battery short circuit, battery failure, etc., to improve flatness, weaken the effect of lead lug welding stress, lead lug Uniform effect of welding points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

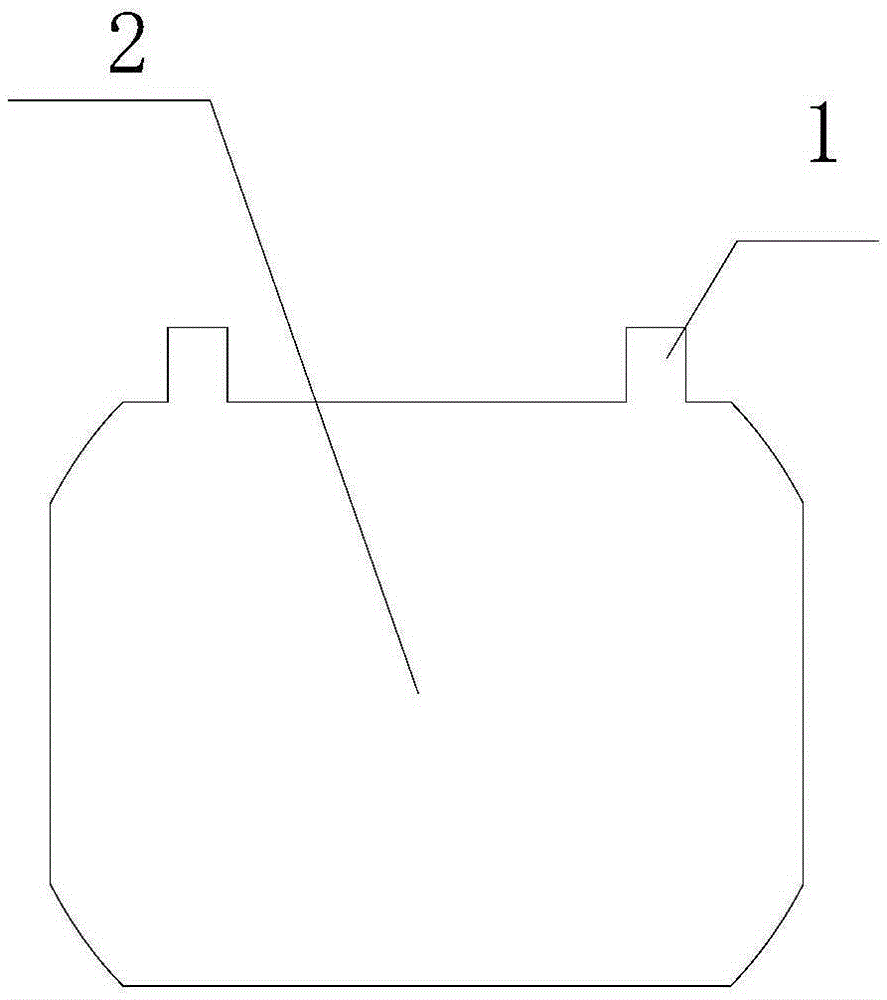

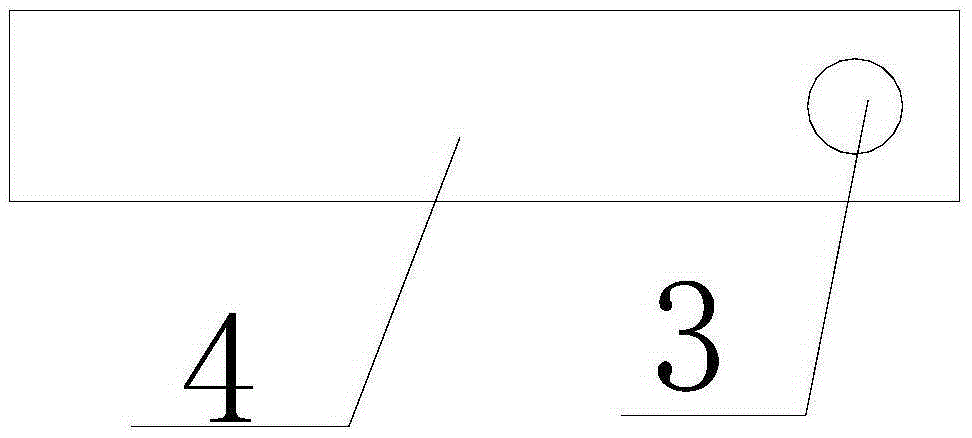

[0029] see figure 1 , a kind of preparation method of macroporous silver electrode, following steps:

[0030] Step 101, manufacturing a large-porosity blank silver electrode:

[0031] The raw material for the large-porosity rough silver electrode is silver acetate powder, and the electrode skeleton is silver mesh. The preparation method adopts a one-time roll forming method; the specific steps are: put the silver acetate powder into the hopper of the roller press, and put the silver mesh into the reel of the roller press , start the roller press, adjust the thickness of the prepared silver electrode to 0.45-0.55mm, generally the preferred thickness of the silver electrode is 0.45mm, 0.5mm, or 0.55mm, and then cut it into the required size; u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com