Moving coil gas-magnetism combined air-suspension double-workpiece-stage vector circular-arc exchange method and device based on staggered magnetic steel arrangement

A technology of double workpiece table and workpiece table, which is applied to the exposure device of the photoplate making process, the photoplate making process of the pattern surface, optics, etc. The main structure of the engraving machine is increased, etc., to achieve the effect of shortening the time for changing channels, improving the efficiency of changing channels, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

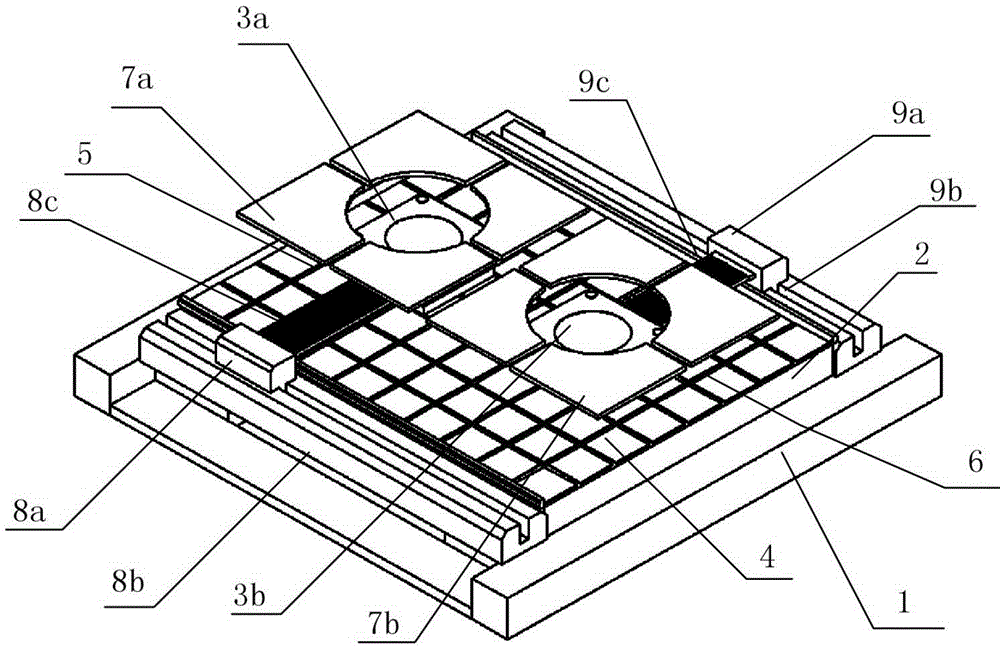

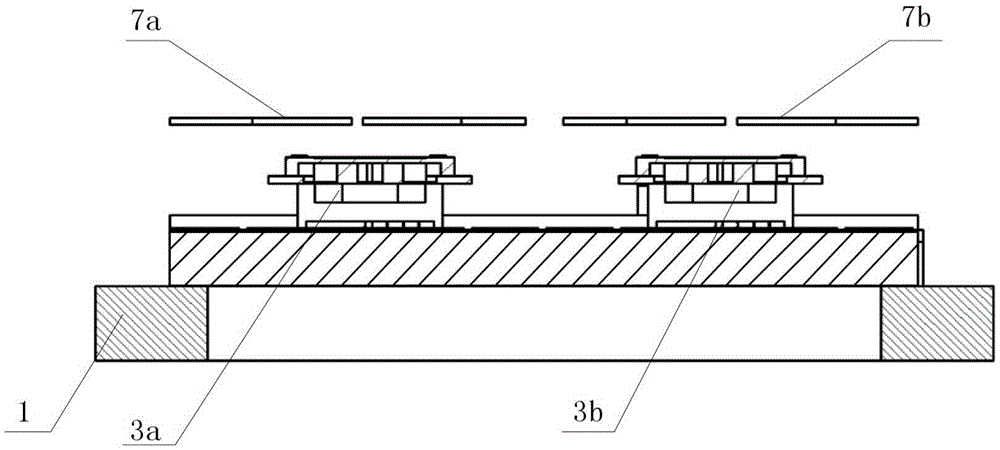

[0024] Below in conjunction with accompanying drawing, embodiment of the present invention is described in further detail:

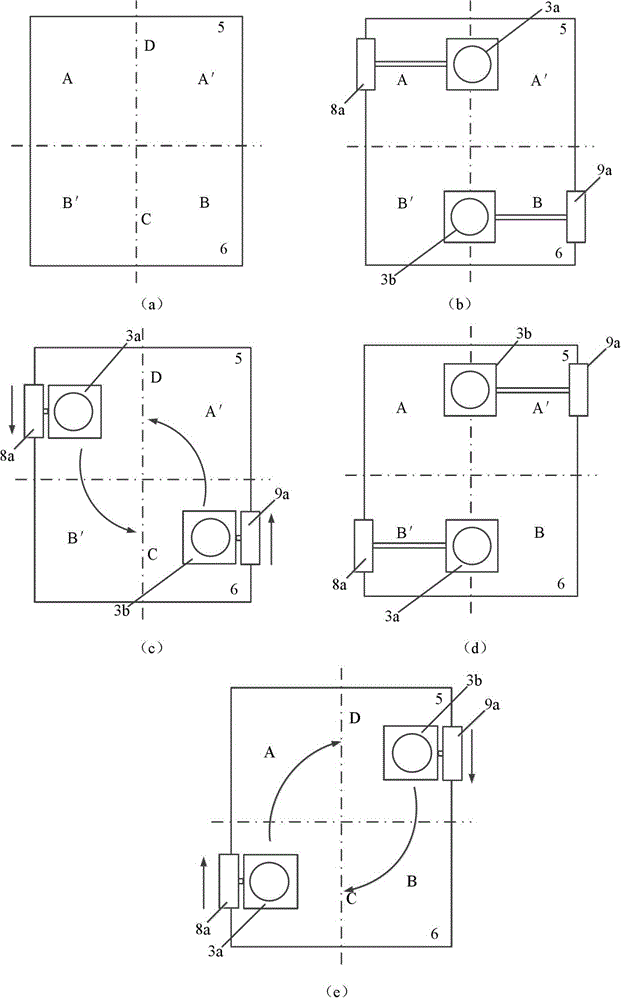

[0025] The moving coil aeromagnetism combined with air-flotation double workpiece stage vector arc transfer method based on the staggered magnetic steel arrangement includes the following steps: initial working state, the first workpiece stage at the measurement position is in a pre-aligned state, and the second workpiece stage at the exposure position In the exposure state; in the first step, after the pre-alignment of the first workpiece table at the measurement position, it is driven by the moving coil to move to the preset position A of the measurement position and waits, and the second work table at the exposure position is driven by the moving coil to move to The exposure position is changed to the predetermined position B; in the second step, the first workpiece table and the second workpiece table move counterclockwise along the circular arc track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com