Double-workpiece-platform same-phase rotation exchange method based on parallel connection mechanisms, and device thereof

A technology of double worktable and worktable, which is applied in the field of double worktable rotary exchange in the same phase, can solve the problems of laser interferometer target loss, shorten the balance time, and large impact torque, so as to improve the efficiency of stage change, shorten the The effect of channel change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

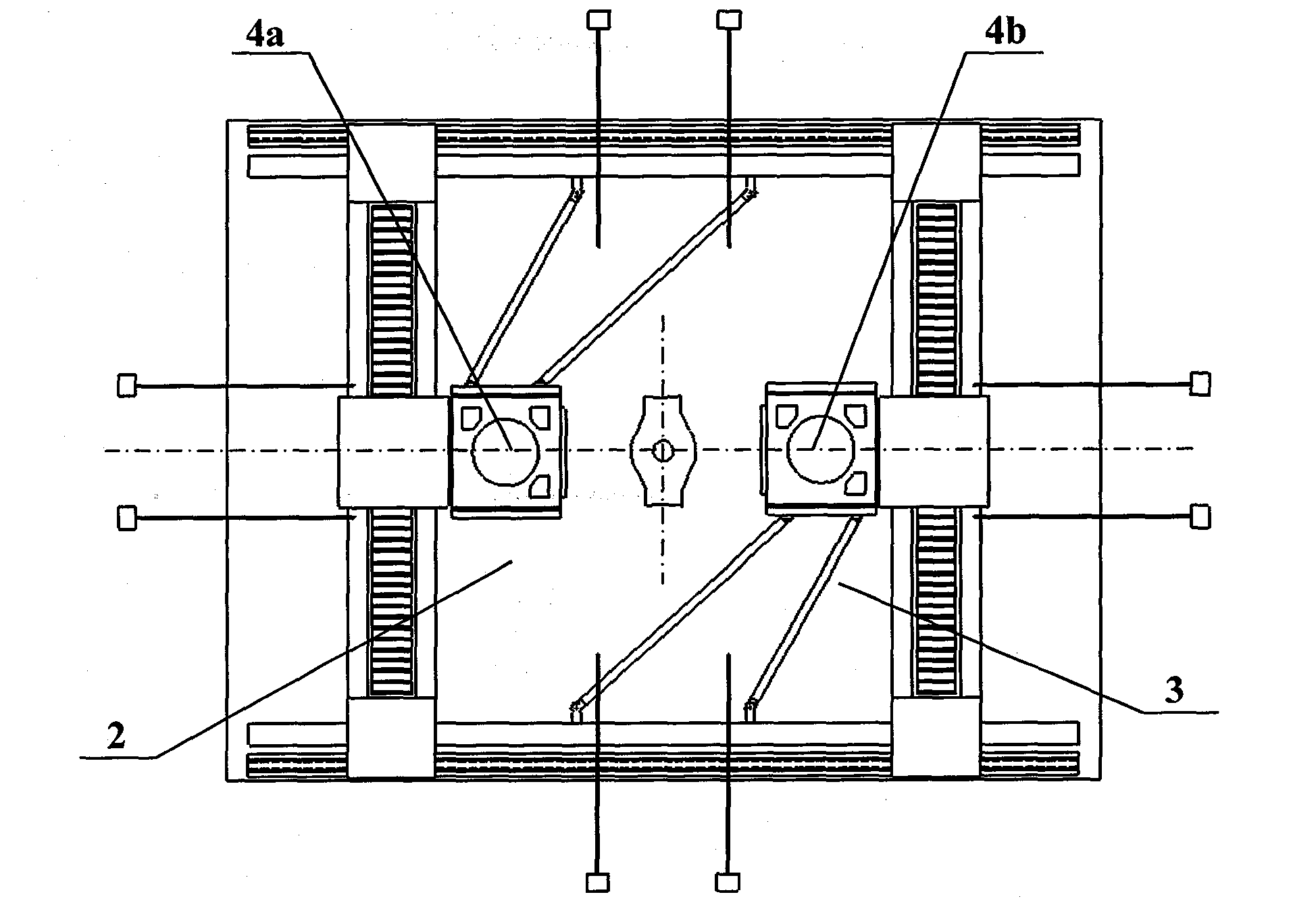

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, embodiment of the present invention is described in further detail:

[0023] Based on the parallel mechanism, the double-workpiece stage rotation exchange method in the same phase is composed of three beats. The first beat is: after the first worktable completes the exposure process and the second workbench completes the pretreatment process, respectively from the exposure work The station and the pretreatment station move to the center of the abutment, and the clamping device of the rotary conversion table electromagnetically absorbs the first workpiece table rotary ring sleeve of the first workpiece table and the second workpiece table rotary ring sleeve of the second workpiece table. At the same time, X Loosen the first workpiece table adapter device of the first workpiece table and the second workpiece table adapter device of the second workpiece table respectively to the gripping mechanism on the first linear motor mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com