A method for controlling the process of changing stages in a double-workpiece stage system

A technology of double workpiece table and process control, which is applied in the direction of photolithography process exposure device, microlithography exposure equipment, etc., can solve the problems of large impact of table body and low positioning accuracy of workpiece table.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

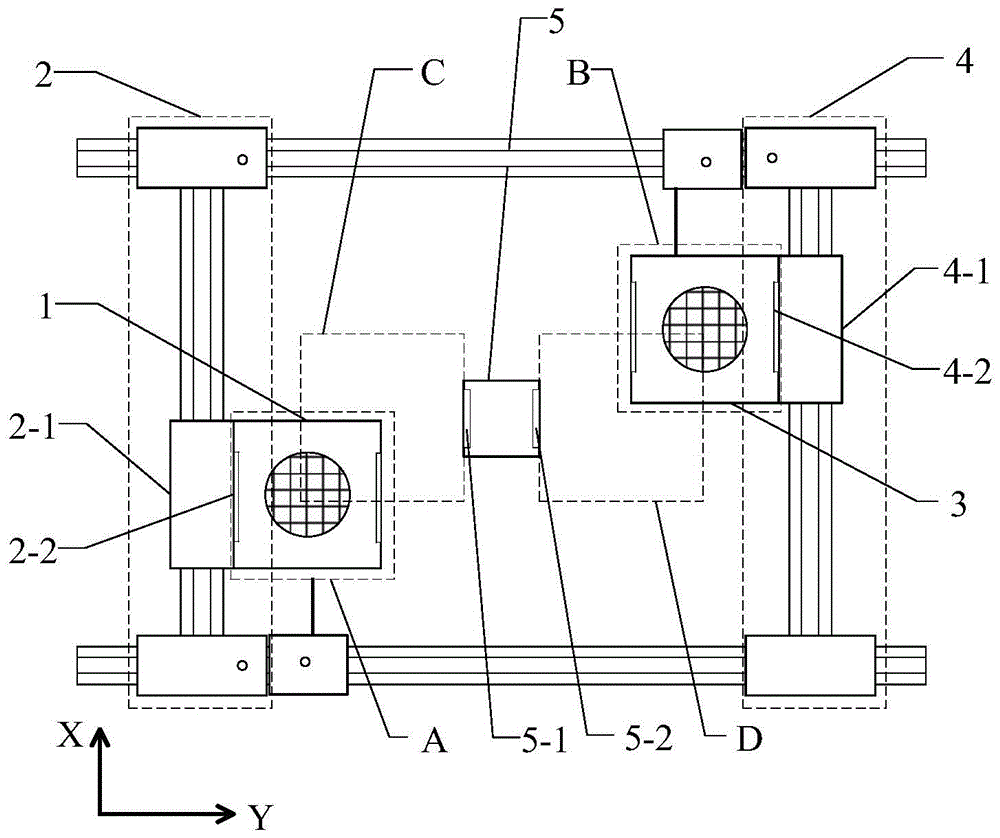

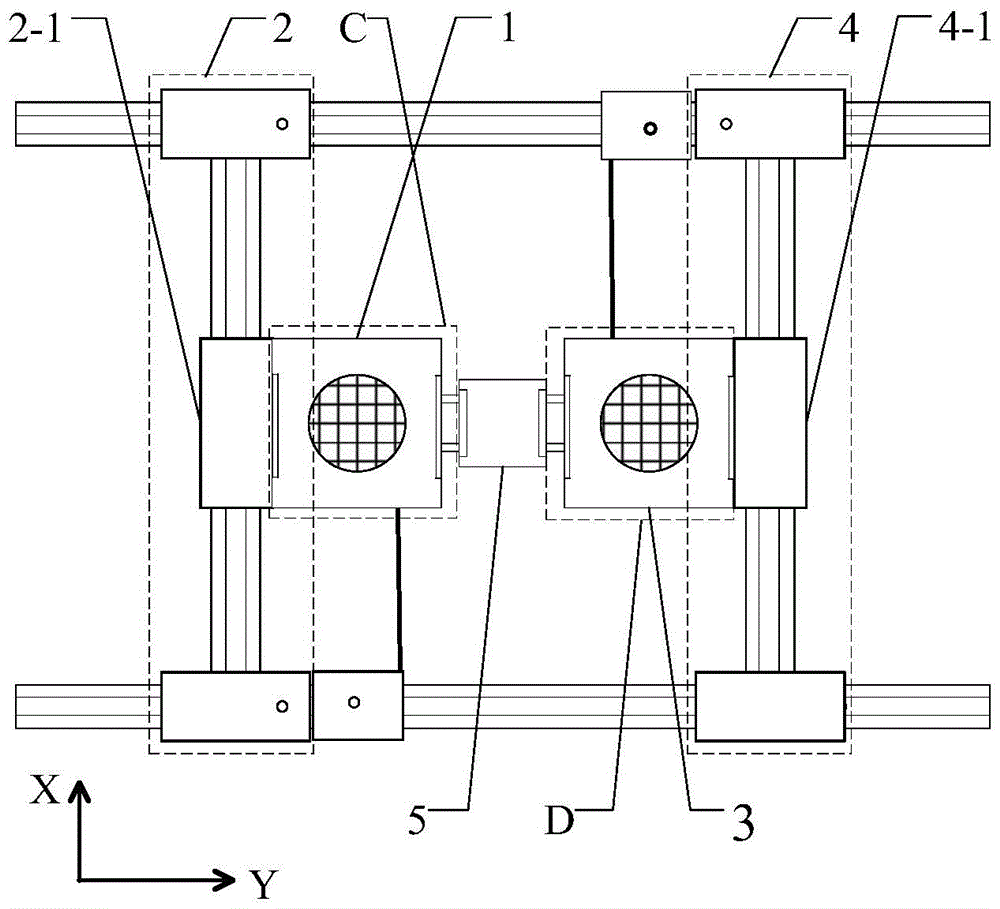

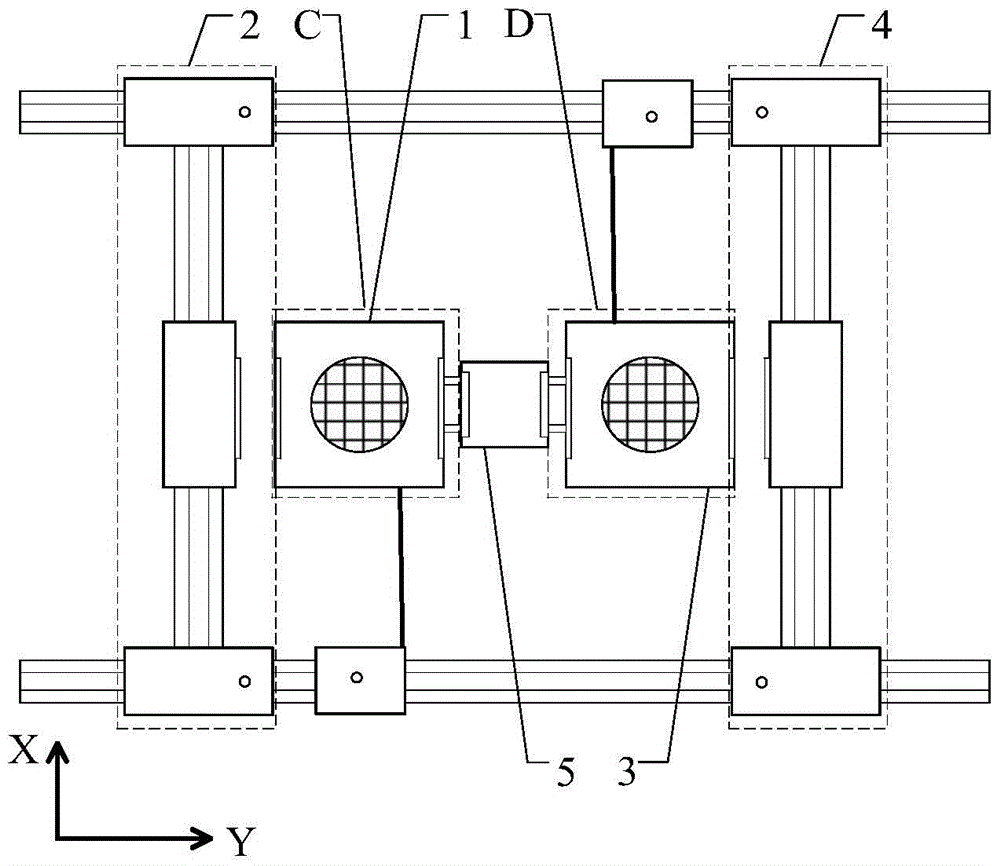

[0027] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, its method steps are:

[0028] Step 1: The first clamping mechanism 2-2 on the first X-direction moving platform 2-1 in the first horizontally moving platform assembly 2 grabs the first workpiece table 1, and the first horizontally moving platform assembly 2 Move the first workpiece table 1 to the left pretreatment working position A through its own Y-direction movement and the X-direction movement of the first X-direction moving platform 2-1; The second clamping mechanism 4-2 on the second X-direction moving platform 4-1 grabs the second workpiece table 3, and the second horizontal moving platform assembly 4 moves through its own Y direction and the second X direction The X-direction movement of the mobile platform 4-1 moves the second workpiece table 3 to the right exposure working position B;

[0029] Step 2: After the preprocessing work and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com